System, method and device for controlling material transfer

A transfer device and control device technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems that the travel position of the material transfer device cannot be predicted in advance, and it is impossible to accurately control the operation of the transfer device, so as to avoid potential safety hazards and improve efficiency. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

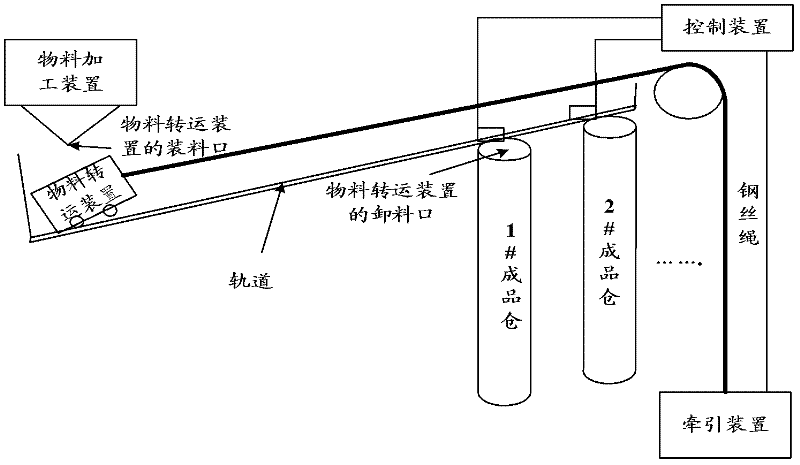

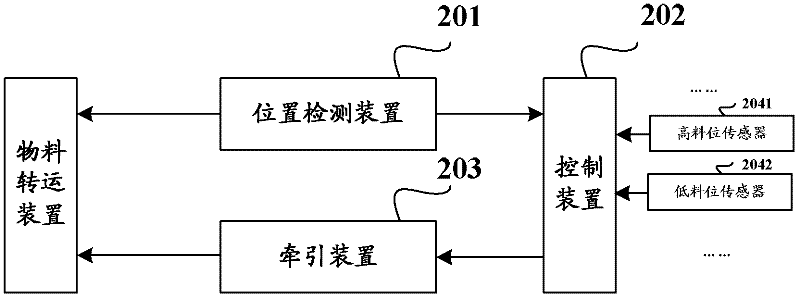

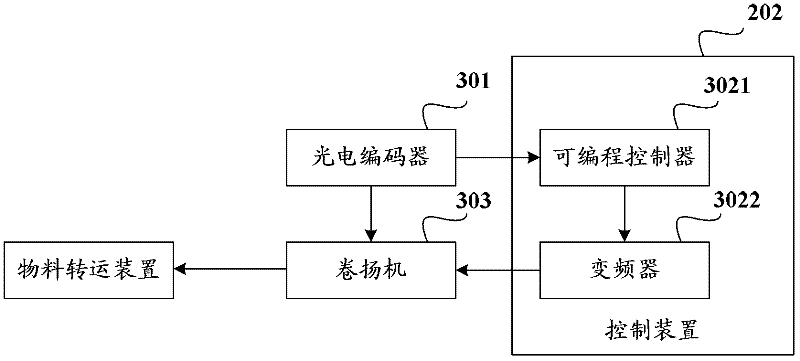

[0037] Such as figure 1 As shown, it is a schematic diagram of the principle of the material transfer control system provided by the embodiment of the present invention. There can be one finished product warehouse for the material, or multiple parallel ones, such as the No. 1 finished product warehouse and No. 2 finished product warehouse shown in the figure. The material transfer device of asphalt mixture is pulled by the traction equipment, and can run along the track from the discharge port of the mixing main engine to the material connection port of the finished product warehouse. For the material transfer device, the discharge port of the material processing device is the material transfer device The first interface for loading materials and the material receiving port of the finished product warehouse are the second interface for unloading materials from the material transfer device. The positions of the first interface and the second interface of each finished product wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com