Preparation method and application of composite flocculant

A composite flocculant and reaction technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of narrow effective concentration range, seldom used alone, and less sludge generated, and achieves wide application range, adsorption bridging High capacity and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

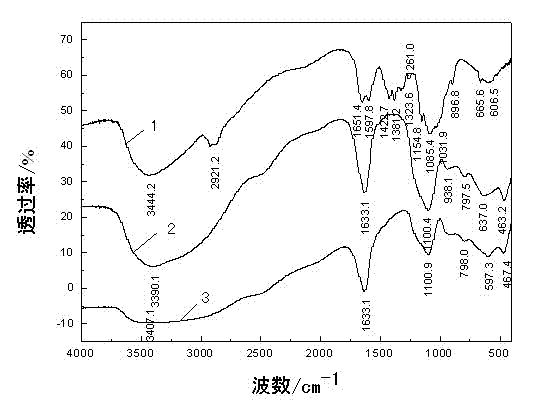

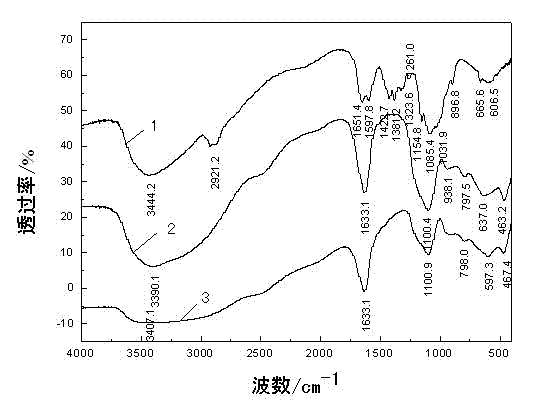

Image

Examples

Embodiment 1

[0021] Effect of Mass Ratio on Flocculation Effect of Composite Flocculants

[0022] Chitosan was dissolved in 1% acetic acid aqueous solution to form a stock solution with a concentration of 3 g / L, and polysilicate aluminum chloride ferric chloride solution was added under magnetic stirrer stirring, and the mass ratio of PSAFC and CTS was respectively set as 1:2, 1:1, 2:1, 3:1, 4:1, 5:1, 6:1, add 10% dilute hydrochloric acid dropwise to adjust the pH value to 2, stir vigorously to make it evenly mixed. Slowly heated to 70 °C, reacted at a constant temperature for 30 min, and cooled naturally to room temperature to prepare a composite flocculant, which was subjected to flocculation experiments of cyanobacterial biogas slurry.

[0023]Take 250 mL of cyanobacteria wastewater, the turbidity is 112 NTU, the TP is 87 mg / L, the dosage of PSAFC-CTS composite flocculant is 2.5 mL, and the electric stirrer is used to stir rapidly (300 r / min) and then slowly ( 100 r / min) stirring, afte...

Embodiment 2

[0025] Effect of pH value on flocculation effect of composite flocculant

[0026] Get chitosan and be dissolved in volume fraction and be that 1% acetic acid aqueous solution is made into the stock solution that concentration is 3 g / L, under the situation that guarantees raw material proportioning is 5:1, add polysilicate aluminum chloride under magnetic stirrer stirring Iron solution, the mass concentration is 10% dilute hydrochloric acid or the mass concentration is 10% sodium hydroxide to adjust the pH value, and the pH value conditions are set to 1, 1.5, 2, 2.5, 3, 4, 5, 6, 7, 8 respectively , 10. Slowly heated to 70 °C, reacted at constant temperature for 30 min, and cooled naturally to room temperature. After preparing the composite flocculant, the cyanobacterial biogas slurry flocculation experiments were carried out respectively.

[0027] Take 250 mL of cyanobacteria wastewater, the turbidity is 125 NTU, the TP is 91 mg / L, the dosage of PSAFC-CTS composite flocculant ...

Embodiment 3

[0029] Effect of Reaction Temperature on Flocculation Effect of Composite Flocculants

[0030] Get chitosan and be dissolved in volume fraction and be that 1% acetic acid aqueous solution is made into the stock solution that concentration is 3 g / L, under the situation that guarantees raw material proportioning is 5:1, add polysilicate aluminum chloride under magnetic stirrer stirring Iron solution, add 10% dilute hydrochloric acid dropwise to adjust pH=2.5, stir vigorously to make it evenly mixed. Set up to heat slowly to 40 °C, 50 °C, 60 °C, 70 °C, and 80 °C respectively, and the reaction time is 30 min, then cool naturally to room temperature, and carry out flocculation experiments on the prepared composite flocculants respectively.

[0031] Take 250 mL of cyanobacteria wastewater, the turbidity is 103 NTU, the TP is 110 mg / L, the dosage of PSAFC-CTS composite flocculant is 2.5 mL, and the electric stirrer is used to stir rapidly (300 r / min) and then slowly ( 100 r / min) sti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap