Submersible aerator

A kind of aerator, submersible technology, applied in water aeration, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of short service life, not stable enough, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

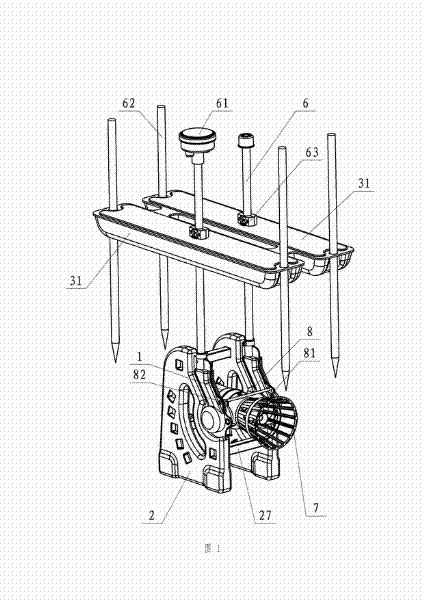

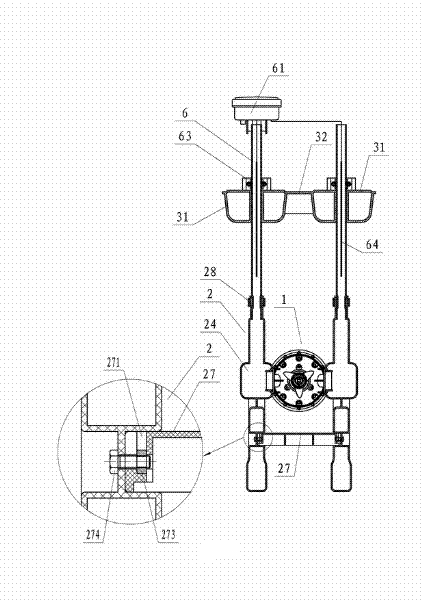

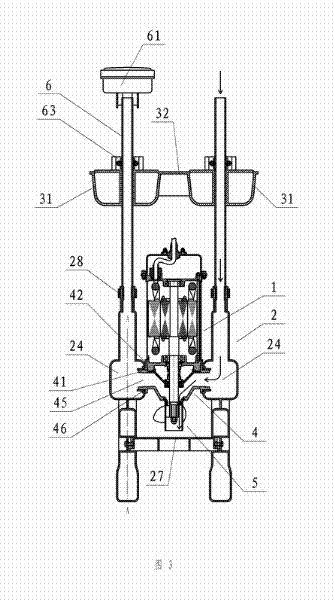

[0037] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-12 :

[0038] A submersible aerator of the present invention is mainly composed of a floating body 3, a submersible motor 1, a base 2 and an air intake channel, etc., the floating body 3 is two conjoined pontoons 31 formed by blow molding at one time. The two pontoons 31 each have a hole 311 that can pass through the air intake pipe 6 up and down, and the air intake passage is: the bottoms of the two air intake pipes 6 are respectively fixed in the connecting ports 23 of the left and right bases 2, and the left and right The two bases are hollow bodies formed by blow molding. There is a base air passage 24 in the base 2. The base air passage is a closed passage sealed by an isolation belt 26. The upper end of the base air passage 24 is the connection port 23 of the air intake pipe 6. , the lower end of the air channel of the base commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com