Thermosetting reflection thermal insulation coating and preparation method thereof

A reflective thermal insulation coating, thermosetting technology, applied in the direction of reflective/signal coatings, coatings, etc., can solve the problems of less heat and light reflective functional pigments, affecting the solar heat reflectivity, adding too much filler, etc., to achieve shrinkage The effect of low rate, good stain resistance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

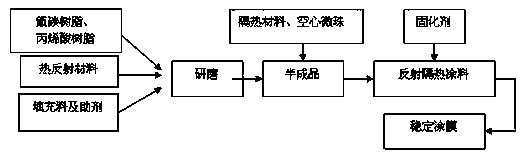

Method used

Image

Examples

Embodiment 1

[0032]First, 100 kg of fluorocarbon resin, 30 kg of acrylic resin, 40 kg of rutile titanium dioxide, 20 kg of silicon dioxide, 0.5 kg of dispersant BYK-116, 0.5 kg of leveling agent BYK-358N, and 0.4 kg of defoamer BYK-141 , Anti-sedimentation agent BYK-410 0.6 kg is uniformly mixed in a high-speed disperser, the speed is 1000-1400 rpm, and the time is 15 minutes; the mixed material is ground three times by a sand mill, and the time for each time is about 1 hour. When the fineness reaches below 25 microns, it can be used as a semi-finished product; then add the measured hollow microspheres to the semi-finished product, and then stir for 20 minutes at a speed of 600-800 rpm, and finally the finished thermosetting reflective heat insulation can be obtained coating. When used, the weight ratio is: thermosetting reflective heat-insulating coating: curing agent = 100:10; add biuret, stir well, and use after 30 minutes of curing.

Embodiment 2

[0034] First, 120 kg of fluorocarbon resin, 35 kg of acrylic resin, 50 kg of rutile titanium dioxide, 25 kg of silicon dioxide, 0.6 kg of dispersant BYK-116, 0.6 kg of leveling agent BYK-358N, and 0.5 kg of defoamer BYK-141 , Anti-sedimentation agent BYK-410 0.6 kg is uniformly mixed in a high-speed disperser, the speed is 1000-1400 rpm, and the time is 15 minutes; the mixed material is ground three times by a sand mill, and the time for each time is about 1 hour. When the fineness reaches below 25 microns, it can be used as a semi-finished product; then add the measured hollow microspheres to the semi-finished product, and then stir for 20 minutes at a speed of 600-800 rpm, and finally the finished thermosetting reflective heat insulation can be obtained coating. When used, the weight ratio is: thermosetting reflective heat-insulating coating: curing agent = 100:10; add biuret, stir well, and use after 30 minutes of curing.

Embodiment 3

[0036] First, 150 kg of fluorocarbon resin, 40 kg of acrylic resin, 60 kg of rutile titanium dioxide, 30 kg of silicon dioxide, 0.8 kg of dispersant BYK-116, 0.8 kg of leveling agent BYK-358N, 0.6 kg of defoamer BYK-141 kg, anti-sedimentation agent BYK-410 is 0.8 kg, and is uniformly mixed in a high-speed disperser at a speed of 1000-1400 rpm for 15 minutes; the mixed material is ground three times by a sand mill, and the time for each pass is about 1 Hours, when the fineness reaches below 25 microns, it can be used as a semi-finished product; then add the measured hollow microspheres to the semi-finished product, and then stir for 20 minutes at a speed of 600-800 rpm, and finally the finished heat-cured reflector can be obtained. Insulation paint. When used, the weight ratio is: thermosetting reflective heat-insulating coating: curing agent = 100:10; add biuret, stir well, and use after 30 minutes of curing.

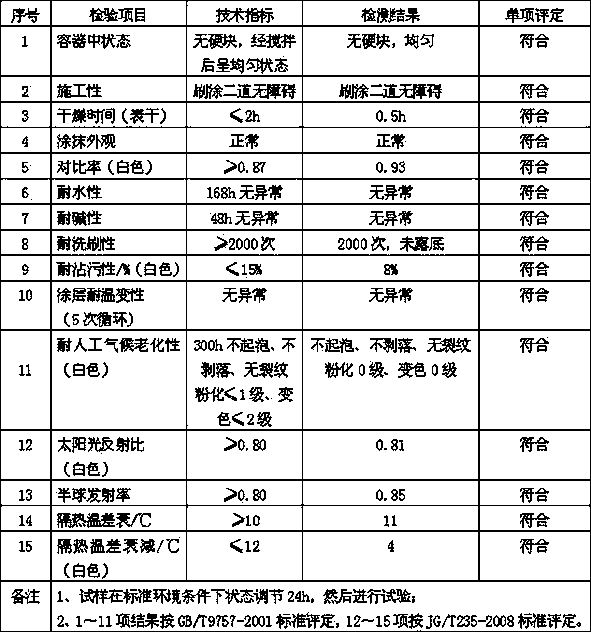

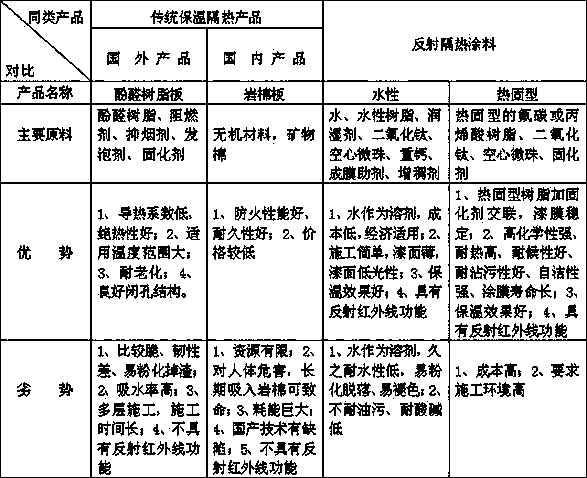

[0037] Comparison of the characteristics of reflective thermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com