Slag pouring barrel for electroslag remelting

An electroslag remelting and slag pouring technology is applied in the field of metallurgical supplies, which can solve the problems of slag solidification and easy ironing through, and achieve the effects of preventing slag solidification, preventing ironing through, and slowing down the temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

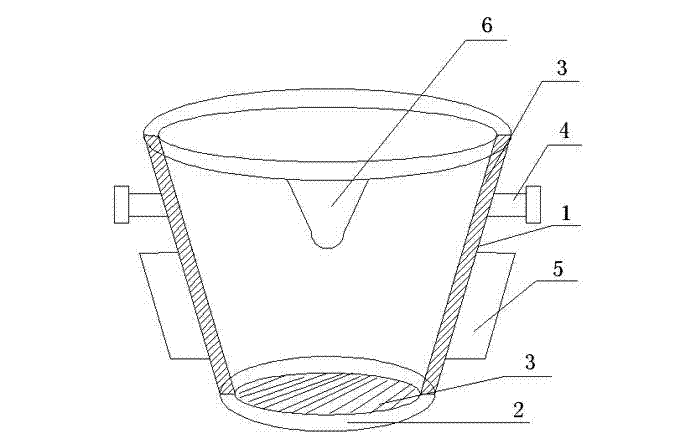

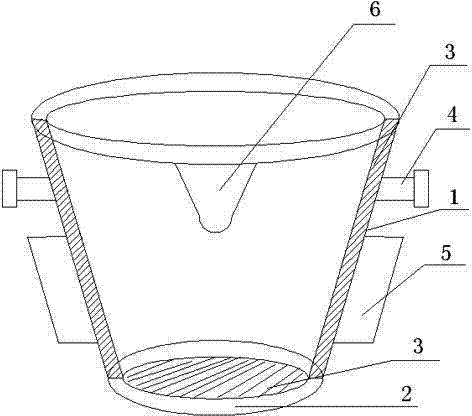

[0010] Such as figure 1 As shown, an electroslag remelting slag dumping bucket includes a bucket body 1 and a bucket bottom 2, and is characterized in that: the bucket body 1 has an insulation layer 3 inside (the insulation layer is made of refractory and insulation materials to achieve heat preservation The purpose of preventing scalding).

Embodiment 2

[0012] An electroslag remelting slag dumping bucket is the same as the first embodiment. The difference is that: the bucket body is also designed with a lifting lug 4, which can facilitate the lifting of driving.

Embodiment 3

[0014] An electroslag remelting slag dumping bucket is the same as the first embodiment. The difference is that: the top of the bucket is designed with a nozzle 6 to facilitate slag dumping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com