Low-alloy high-strength wide and thin steel plate

A low-alloy high-strength, steel plate technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as difficulty in controlling the shape of finished steel plates, affecting the performance of wide and thin steel plates, and economic losses of enterprises. Achieve the effect of reducing unplanned quantity, shortening production cycle and improving rolling rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

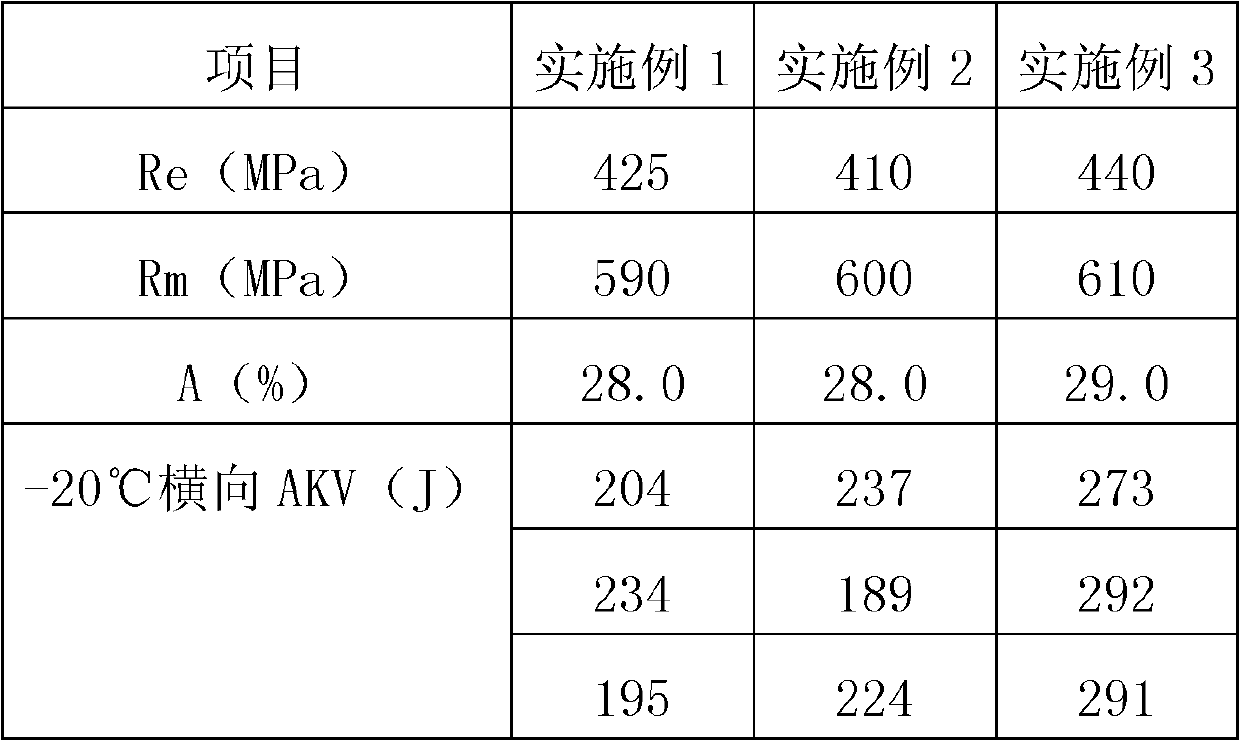

Embodiment 1

[0017] This embodiment is a specific embodiment of low-alloy high-strength wide thin steel plate, which is composed of the following chemical components in weight percentage: C 0.14%, Si 0.55%, Mn 1.6%, P 0.014%, S 0.030%, V 0.36%, the balance is Fe and unavoidable impurities.

[0018] The production method of the low-alloy high-strength wide thin steel plate of this embodiment comprises the following steps:

[0019] Steelmaking process: The molten steel is first smelted in an electric furnace to ensure slag-free tapping, and a deoxidizer is added to the molten steel for pre-deoxidation; the tapping temperature is 1560-1600°C; then it is sent to the LF refining furnace for refining to strengthen the deoxidation and ensure the white slag retention time 40min, the total effective refining time is 60min; finally vacuum treatment in VD furnace, the vacuum treatment time is below 66Pa and the holding time is ≥ 15 minutes;

[0020] Heating billet step: Put the billet into the heati...

Embodiment 2

[0023] This embodiment is a specific embodiment of low-alloy high-strength wide thin steel plate, which is composed of the following chemical components in weight percentage: C 0.18%, Si 0.40%, Mn 1.4%, P 0.011%, S 0.030%, V 0.34%, the balance is Fe and unavoidable impurities.

[0024] The production method of the low-alloy high-strength wide thin steel plate of this embodiment comprises the following steps:

[0025] Steelmaking process: The molten steel is first smelted in an electric furnace to ensure slag-free tapping, and a deoxidizer is added to the molten steel for pre-deoxidation; the tapping temperature is 1560-1600°C; then it is sent to the LF refining furnace for refining to strengthen the deoxidation and ensure the white slag retention time 20min, the total effective refining time is 40min; finally vacuum treatment in VD furnace, the vacuum treatment time is below 66Pa and the holding time is ≥ 15 minutes;

[0026] Heating billet step: Put the billet into the heati...

Embodiment 3

[0029] This embodiment is a specific embodiment of low-alloy high-strength wide thin steel plate, which is composed of the following chemical components in weight percentage: C 0.17%, Si 0.30%, Mn 1.43%, P 0.012%, S 0.030%, V 0.35%, the balance is Fe and unavoidable impurities.

[0030] The production method of the low-alloy high-strength wide thin steel plate of this embodiment comprises the following steps:

[0031] Steelmaking process: The molten steel is first smelted in an electric furnace to ensure slag-free tapping, and a deoxidizer is added to the molten steel for pre-deoxidation; the tapping temperature is 1560-1600°C; then it is sent to the LF refining furnace for refining to strengthen the deoxidation and ensure the white slag retention time 20min, the total effective refining time is 40min; finally vacuum treatment in VD furnace, the vacuum treatment time is below 66Pa and the holding time is ≥ 15 minutes;

[0032] Steps of heating the billet: Put the billet into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com