High strength low alloy structural normalizing A633GRD steel plate and production method thereof

A high-strength, low-alloy, production method technology, applied in the field of steel plate production, can solve problems such as less production and inability to meet market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

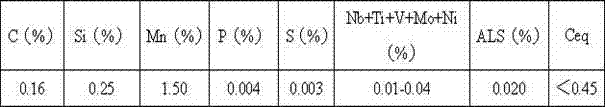

[0032] Through KR molten iron pretreatment, converter smelting, LF refining, VD vacuum refining, continuous casting, heating, rolling, controlled cooling, slow cooling, and normalizing processes, high-strength low-alloy structure normalizing with chemical composition as shown in Table 1 below is obtained Steel plate A633GRD steel plate finished steel, wherein the mechanical properties of the high-strength low-alloy structure normalized steel plate A633GRD steel plate are shown in Table 3 below.

[0033] Table 1 Chemical Composition of Steel in Example 1

[0034]

Embodiment 2

[0036] Through KR molten iron pretreatment, converter smelting, LF refining, VD vacuum refining, continuous casting, heating, rolling, controlled cooling, slow cooling, and normalizing processes, high-strength low-alloy structure normalizing with chemical composition as shown in Table 2 below is obtained Steel plate A633GRD steel plate finished steel, wherein the mechanical properties of the high-strength low-alloy structure normalized steel plate A633GRD steel plate are shown in Table 3 below.

[0037] Table 2 Chemical Composition of Steel in Example 2

[0038]

[0039] The process route of the present invention: KR molten iron pretreatment→converter smelting→LF refining→VD vacuum smelting→continuous casting machine pouring→slab slow cooling→slab heating→slab dephosphorization→TMCP rolling→controlled cooling→steel plate straightening→stacking Pile slow cooling → positive harvest → surface inspection → finishing → flaw detection → performance inspection → qualified products...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com