X70 steel plate for low-cost pipe fittings and production method thereof

A production method and low-cost technology, applied in the field of steel, can solve the problems of high cost, high production difficulty, and large amount of alloy added.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Through molten iron pretreatment, converter smelting, LF refining, VD vacuum refining, continuous steel casting, heating, TMCP rolling, controlled cooling, and stacking and slow cooling processes, the finished Q550D (E) steel plate with the chemical composition described in Table 1 was obtained. The process parameters and mechanical properties are shown in Tables 4 and 5 below.

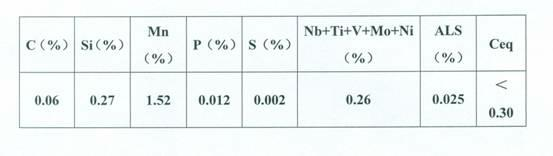

[0032] Table 1 Example 1 steel chemical composition

[0033]

Embodiment 2

[0035] Through molten iron pretreatment, converter smelting, LF refining, VD vacuum refining, continuous steel casting, heating, TMCP rolling, controlled cooling, and stacking and slow cooling processes, the finished Q550D (E) steel plate with the chemical composition described in Table 1 was obtained. The process parameters and mechanical properties are shown in Tables 4 and 5 below.

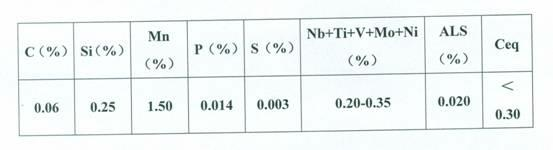

[0036] Chemical composition of table 2 embodiment 2 steel

[0037]

Embodiment 3

[0039] Through molten iron pretreatment, converter smelting, LF refining, VD vacuum refining, continuous steel casting, heating, TMCP rolling, controlled cooling, and stacking and slow cooling processes, the finished Q550D (E) steel plate with the chemical composition described in Table 1 was obtained. The process parameters and mechanical properties are shown in Tables 4 and 5 below.

[0040] The chemical composition of table 3 embodiment 3 steel

[0041]

[0042] The process route of the present invention: KR molten iron pretreatment→converter smelting→LF refining→VD vacuum smelting→continuous casting machine pouring→slab slow cooling→slab heating→slab dephosphorization→TMCP rolling→controlled cooling→steel plate straightening→stacking Pile slow cooling→surface inspection→finishing→flaw detection→performance inspection→qualified product storage.

[0043] 1.1 Steelmaking part

[0044] 1.1.1 Composition design

[0045] Since the steel plate requires high yield strength, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com