Independent pressure foot driving system of embroidering machine

A driving system and technology for embroidery machines, which are used in embroidery machines, embroidery machine mechanisms, textiles and papermaking, etc., can solve the problems of complex structure, sewing material movement, and high cost, and achieve precise movements, simplified structure, and increased pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

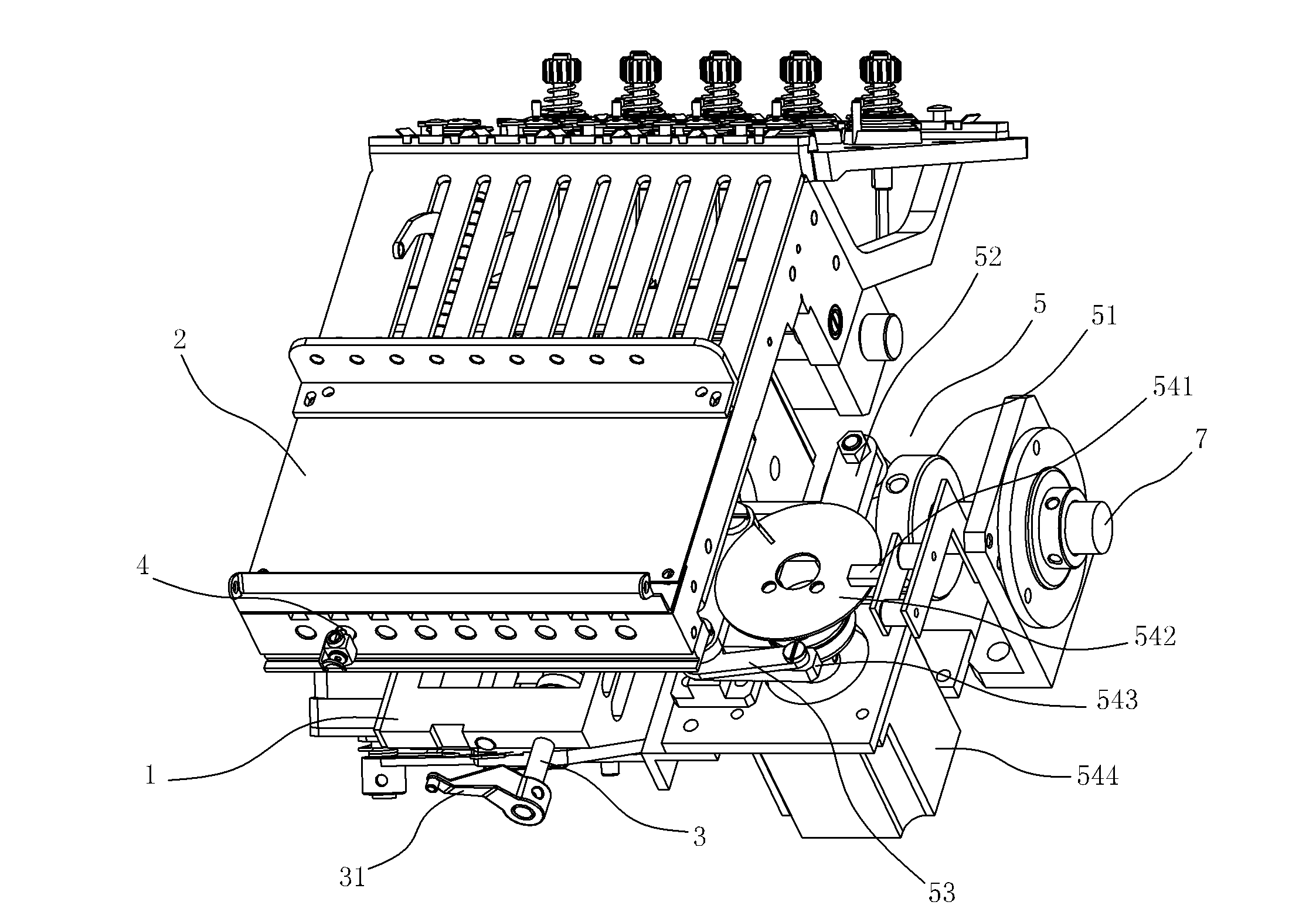

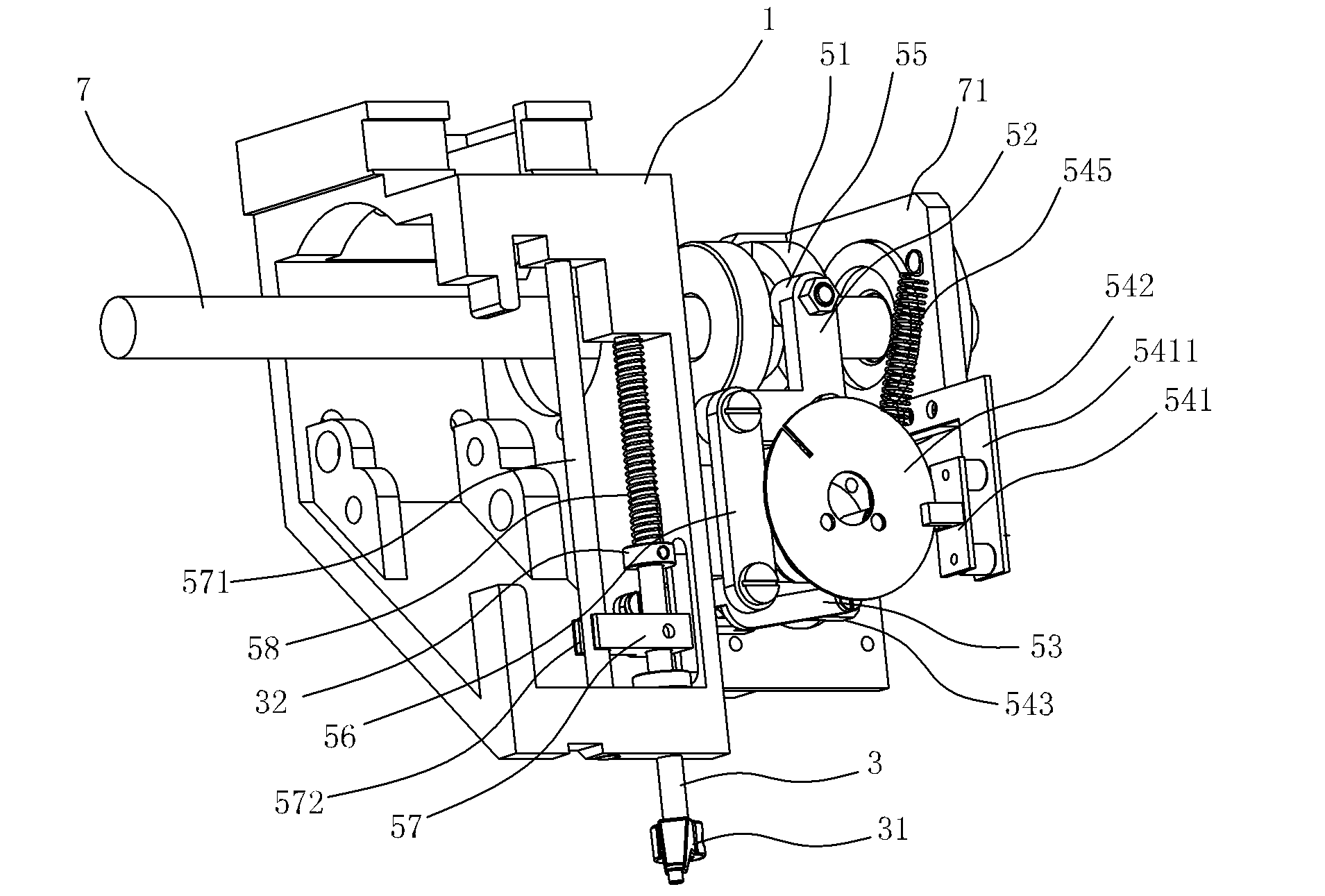

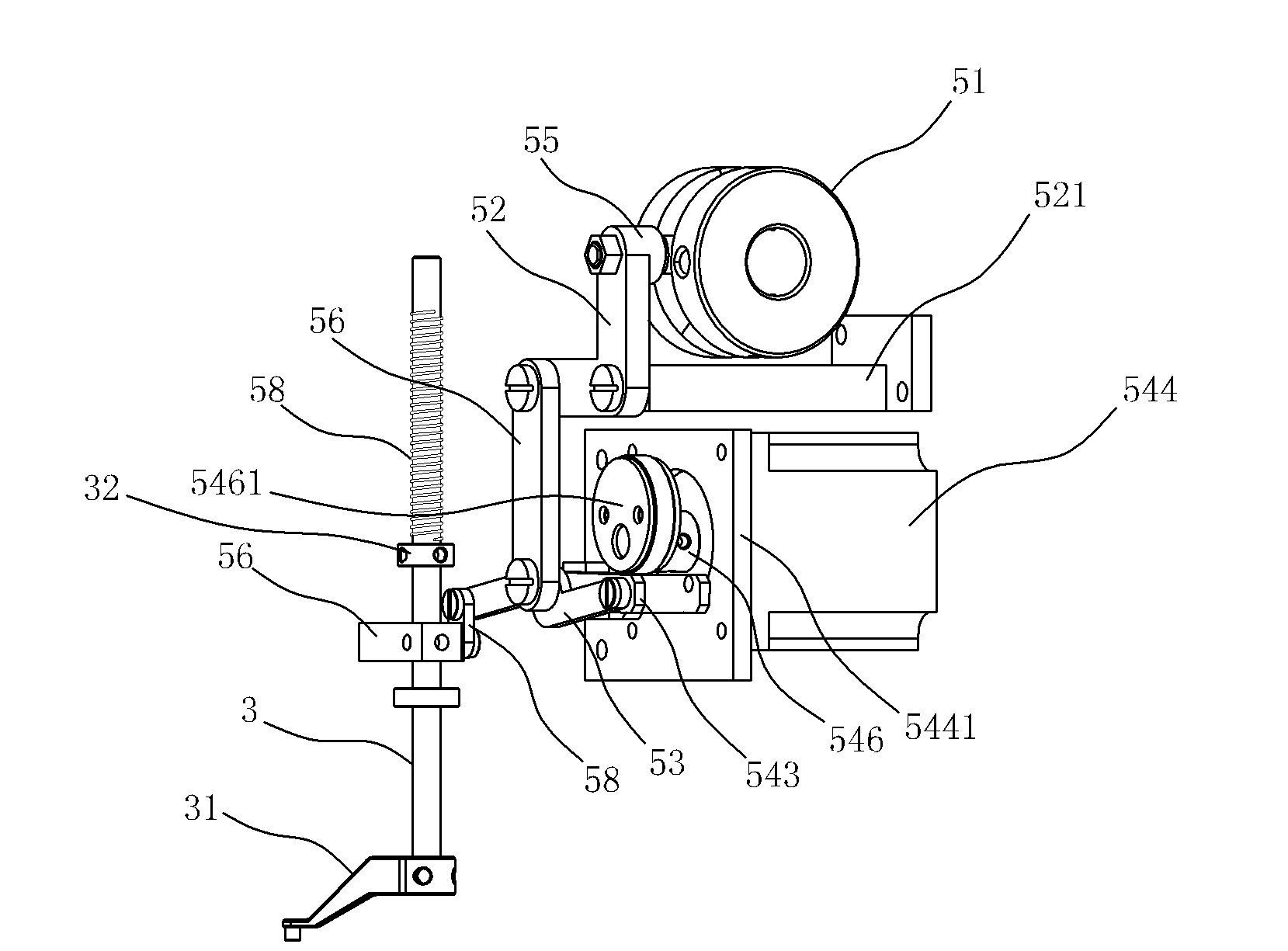

[0018] refer to Figure 1 to Figure 4 Shown, combined with an embroidery machine using an independent presser foot drive system for detailed description:

[0019] An embroidery machine that adopts an independent presser foot drive system includes a frame (not shown in the figure), a machine head 1 arranged on the frame, an upper shaft 7 arranged laterally on the frame 1 through an upper shaft seat 71, which can be horizontally Needle bar box 2 movably arranged on the machine head 1, several needle bars 4 arranged on the needle bar box 2 movable up and down, connected to drive the needle bar box 2 to move laterally to select the color-changing drive for a needle bar 4 to work Mechanism (not shown in the figure), the needle bar driving mechanism (not shown in the figure) that the needle bar 4 that connects the driving selection moves up and down, the presser foot bar 3 that can move up and down arranged on the machine head 1, and the connecting drive The presser foot drive mech...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap