Integrally-moving device for railway turnout junctions

A technology of overall movement and turnout, which is applied to roads, tracks, laying tracks, etc., can solve the problems of unsafe construction process, occupying a large blockage time, and a large amount of manpower and material resources, so as to achieve compact operation procedures, reduce construction time, and save machinery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

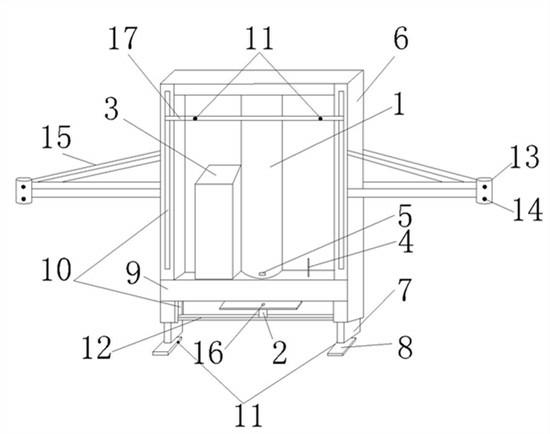

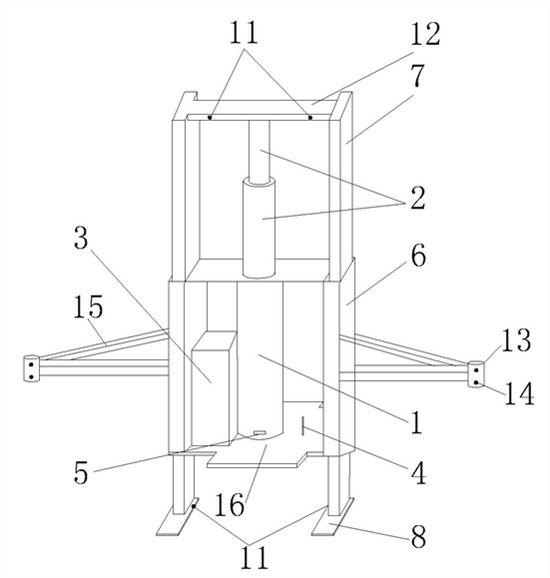

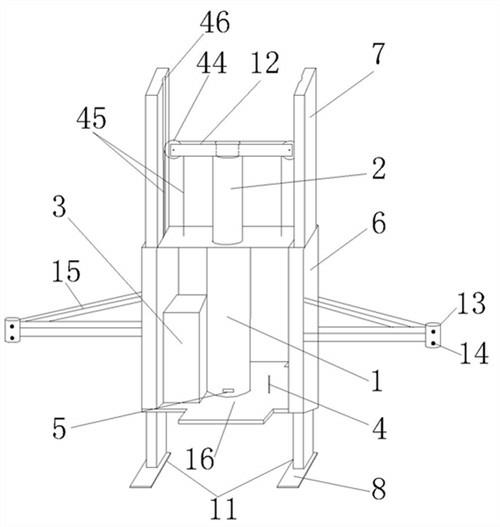

[0076] The present invention will be described in detail according to Figs. 1-12. The whole moving device of the railway turnout moves the whole pre-paved turnout I laterally to the position to be replaced, and a plurality of guide slide rails 42 are arranged within the lateral movement range of the pre-paved turnout I, wherein: at least 5-15 groups of moving units are included, and each group moves The unit is equipped with two fork changing trolleys II, which are respectively arranged on the slide rails 42 at both ends of two adjacent turnout sleepers (two equal-length turnout sleepers should be selected) of the pre-paved turnout I, that is, each slide rail 42 is equipped with two fork changing trolleys Ⅱ. Each turnout trolley II is composed of three parts: hydraulic lifting device, lateral moving block, and longitudinal adjustment block; the hydraulic lifting device uses hydraulic devices to lift or lower the turnout, and the lateral moving block uses a gear set variable fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com