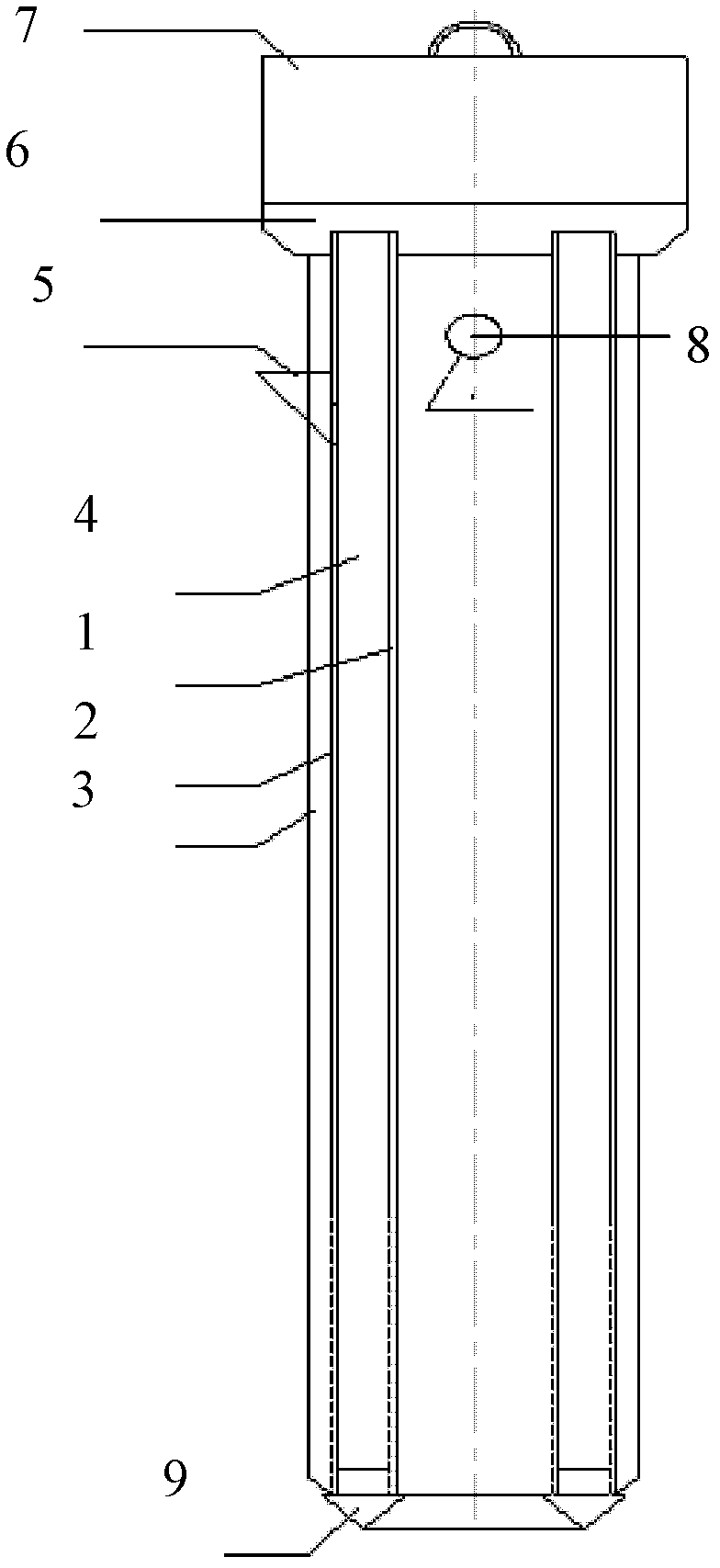

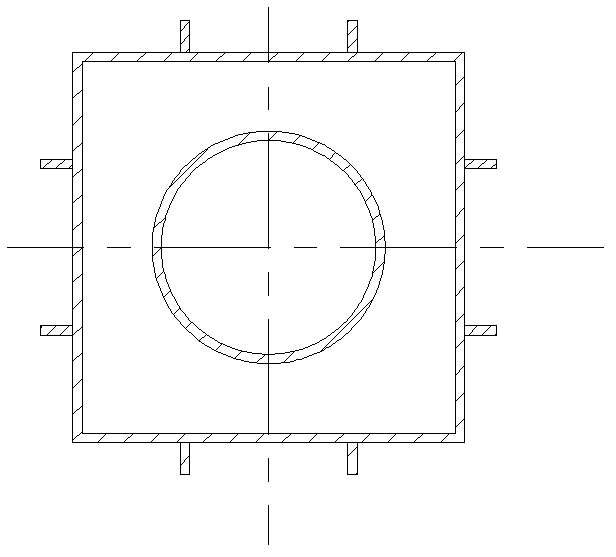

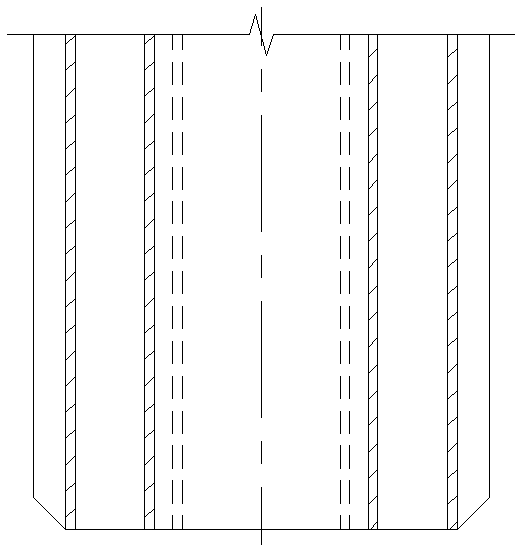

Large-cross-section driven-casing cast-in-place post-grouted concrete hollow square pile and production method thereof

A technology of hollow square pile and immersed tube grouting, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problem that the strength of the pile body and the strength of the steel bar cannot be fully exerted, the moment of inertia, the horizontal and bending stiffness are small, and the horizontal Small bearing capacity and other problems, to achieve the effect of saving project cost, moment of inertia and perimeter, high horizontal bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1: A certain pile foundation project originally used φ800mm bored piles, the section is solid, the circumference of the circular section is small, and the cross-sectional area A=5026cm 2 , section coefficient W=50278cm 3 , moment of inertia I=2010619cm 4 . In addition, when the bored piles are piled, mud is used to protect the walls, and the mud pollution of the site is serious. After the piles are piled, there is mud skin on the pile side and sediment at the pile bottom. Although measures such as pile side and pile end grouting have been taken, the project is located in a deep soft soil area with a small circumference, and the resistance of the pile circumference and pile end soil provides a single pile bearing capacity that is far lower than the design value of the axial compressive strength of the pile body. , the moment of inertia of the section is small, and there are many reinforcements, the strength of the pile body and the strength of the reinforcement...

Embodiment 2

[0064] Example 2: A foundation pit support project, the depth of the foundation pit is 8m, the original use of φ800mm bored piles, the pile spacing is 1000mm, the cross-sectional area A = 5026cm 2 , section coefficient W=50278cm 3 , moment of inertia I=2010619cm 4 , and the bored piles and other piles are formed with mud wall protection, and the mud pollution of the site is serious. The groundwater level is -1.0m, and the soil layer is divided into 5 layers, which are miscellaneous fill, silty clay, silty clay, silt, and silty fine sand. The calculation results of the supporting piles are:

[0065] The maximum positive bending moment is 243.3kN-m, and the maximum negative bending moment is 288.2kN-m;

[0066] The maximum positive shear force is 106.3kN, the maximum negative shear force is -176.8kN, and the total reinforcement is 10Φ22;

[0067] Maximum displacement 27.3mm, cross-sectional area 5026cm 2 , moment of inertia 2019619cm 4 .

[0068] 800×800 perfusion large-se...

Embodiment 4

[0074] Embodiment 4: A certain oil tank foundation project requires the characteristic value of the foundation bearing capacity to reach 180kpa, but the site is in a newly filled deep soft soil area. Although the plastic drainage board is inserted and the preloading process is performed, the characteristic value of the foundation bearing capacity is only Reaching 80kpa, the foundation bearing capacity and foundation settlement cannot meet the requirements of the oil tank foundation. Therefore, the composite foundation schemes of cement-soil mixing piles, CFG piles, plain concrete piles, and immersed tube perfusion plain concrete hollow square piles were compared and selected:

[0075] Cement-soil mixing pile composite foundation scheme: the strength and elastic modulus of the pile body are very low. Under the action of load, the compression of the pile body is large, and the bearing capacity of the single pile is low. The bearing capacity of the composite foundation is greatly r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com