A kind of construction strip and the installation method of the construction strip

A technology for building slats and installation methods, which is applied in the directions of buildings, building components, building structures, etc., can solve the problems of short starting time, difficulty in achieving bonding strength, etc., and achieve the effects of long-lasting effect, easy installation and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

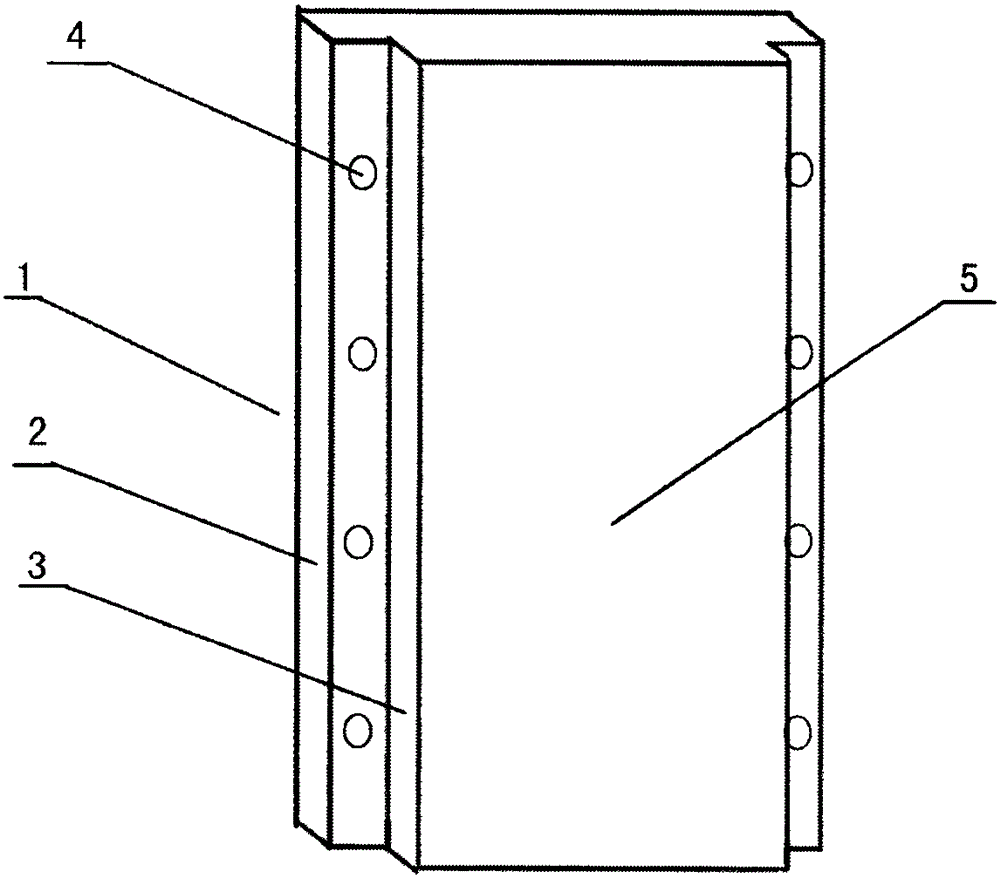

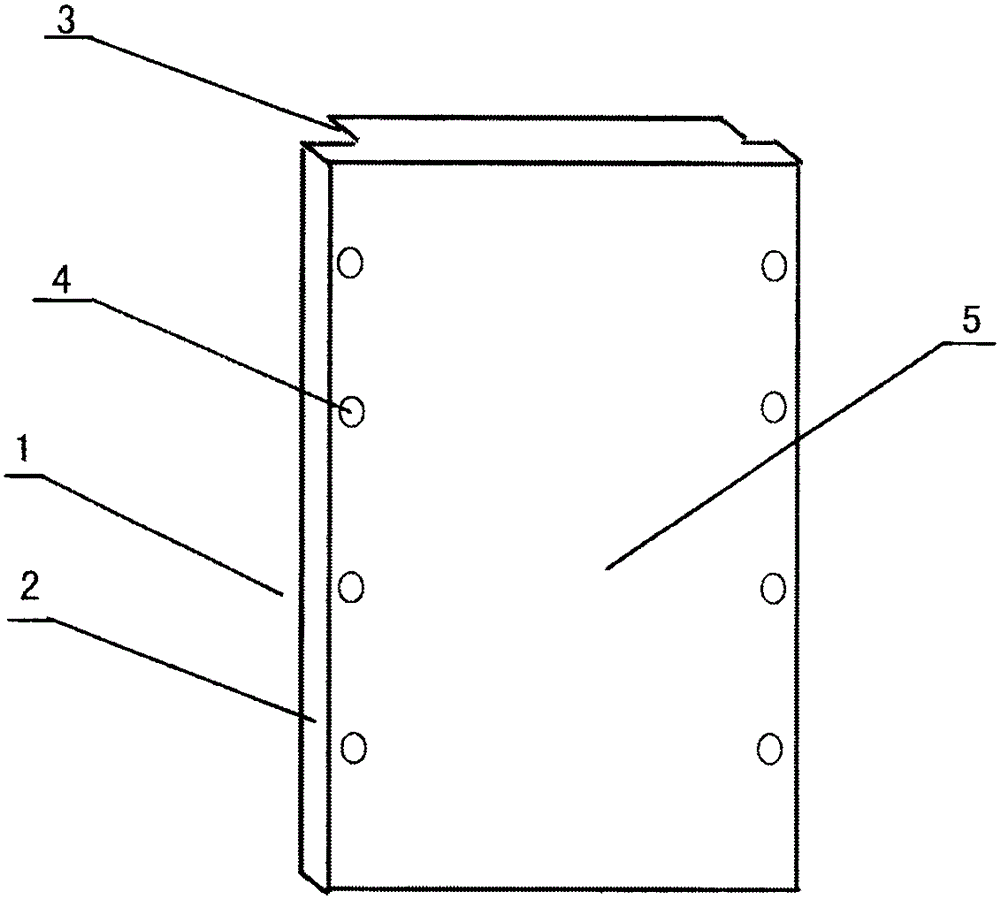

[0017] Such as figure 1 , figure 2 As shown, the side wall 1 of the building slat is divided into two parts, a large half side wall 2 and a small half side wall 3, the big half side wall 2 is wider than the small half side wall 3, and the big half side wall 2 The size and shape of the small half side wall 3 are matched with each other, and several cylindrical holes 4 penetrating the plate surface 5 are arranged on the large half side wall 2 .

example 2

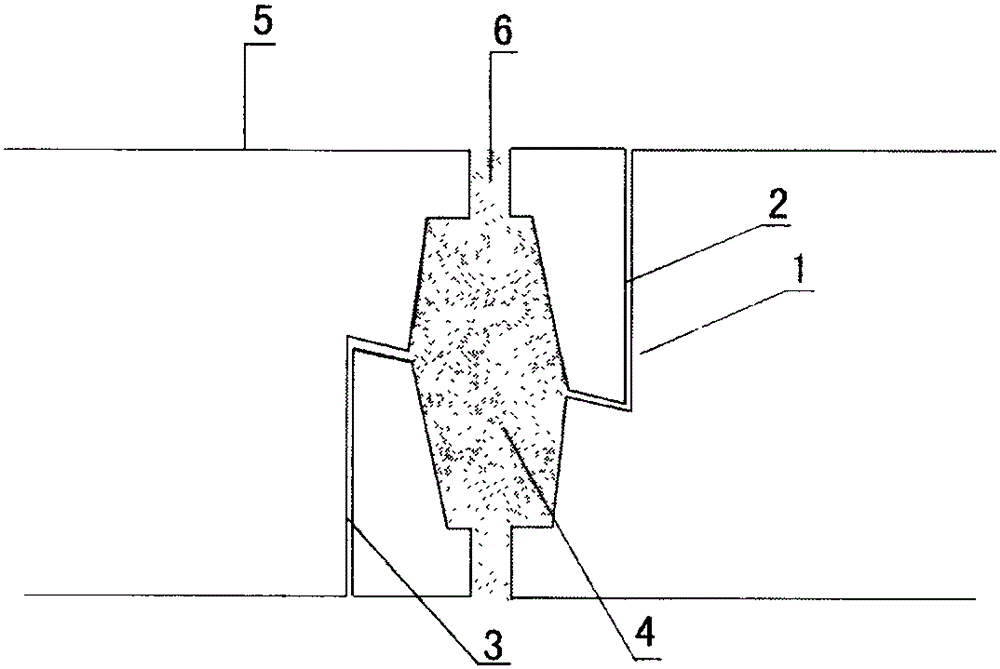

[0019] Such as image 3 As shown, the cylindrical hole 4 designed on the large half side wall 2 does not penetrate the plate surface 5 . An injection hole 6 is provided between the plate surface 5 and the cylindrical hole 4 that does not penetrate the plate surface 5 .

example 3

[0021] Such as Figure 4 As shown, the large half-side wall 2 on one side of a building slat is docked with the small half-side wall 3 on one side of another building slat, and the two large half-side walls 2 are overlapped together at the same time, and the overlapped A pair of cylindrical holes 4 on the two large half-side walls 2 are butted and penetrated, and the prepared slurry is filled in the through cylindrical holes 4, and after the slurry is solidified, two large half-side walls are formed. 2 cylinders, so that the two adjacent plates are firmly connected together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com