Multi-stage draggable water-jet packer tubular column and technology

A technology of hydraulic jet and hydraulic spray gun, applied in the directions of sealing/packing, wellbore/well components, production fluid, etc., can solve the problems of easy failure of the packer, and achieve simple structure, convenient operation, protection and service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

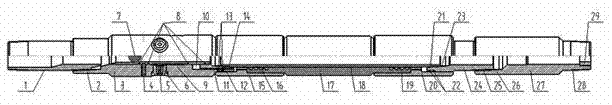

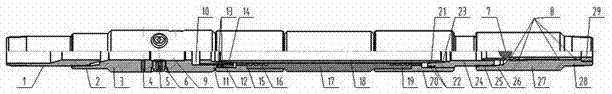

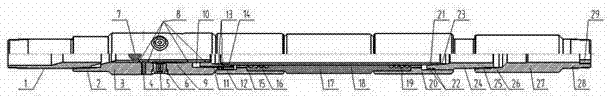

[0013] In order to overcome the problem in the prior art that the packer is prone to failure after being repeatedly set in a high-temperature and high-pressure environment for a long time, this embodiment provides a multi-stage draggable hydraulic jet packer string, including a hydraulic spray gun and a packer The packer is connected to the lower end of the hydraulic spray gun. The specific connection method is that the lower end of the hydraulic spray gun is threadedly connected with the upper end of the center pipe of the packer and the upper end of the rubber cylinder seat, so as to realize the effective integration of the hydraulic spray gun and the packer with two different performance tools. During the construction process, through The method of throwing the ball and slipping the sleeve opens the injection channel of the hydraulic spray gun and the liquid inlet channel of the packer setting at the same time.

[0014] Next, we will describe in detail the structure of a mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com