Method for preparing inert filler for ethylene oxide/glycol device

A technology of inert filler and ethylene oxide, which is applied in chemical instruments and methods, bulk chemical production, chemical/physical processes, etc., can solve problems such as product quality decline, equipment pipeline corrosion, etc., to prolong service life, protect and Long service life, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

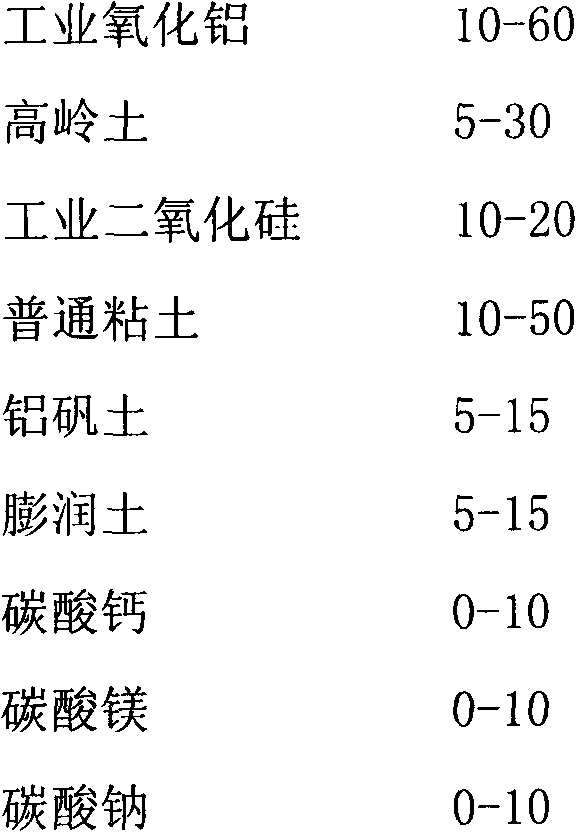

[0019] Example 1: 55% industrial alumina, 20% kaolin, 10% industrial silica, 10% ordinary clay, 5% bentonite, molded with water, calcined at 1500°C for 2 hours, and recorded as sample a.

Embodiment 2

[0020] Example 2: 30% of industrial alumina, 27% of kaolin, 17% of industrial silica, 10% of ordinary clay, 10% of bauxite, 3% of calcium carbonate, 3% of sodium carbonate and water molding, calcined at 1350 ° C for 10 hours, recorded as sample b.

Embodiment 3

[0021] Example 3: 15% industrial alumina, 22% kaolin, 38% ordinary clay, 15% bentonite, 8% calcium carbonate, 2% sodium carbonate, molded with 2% nitric acid, calcined at 1200°C for 8 hours, recorded as sample c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com