Sliding vane pump and method using sliding vane pump to convey fluid

A technology for transporting fluid and sliding vane pumps, which is applied in the hydraulic field, can solve the problems of difficulty in adapting to tubular spaces, large radial dimensions of sliding vane pumps, and small pumping pressure of sliding vane pumps, and achieve a reduction in radial dimensions and radial volume, high lift capacity, effect of potential energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

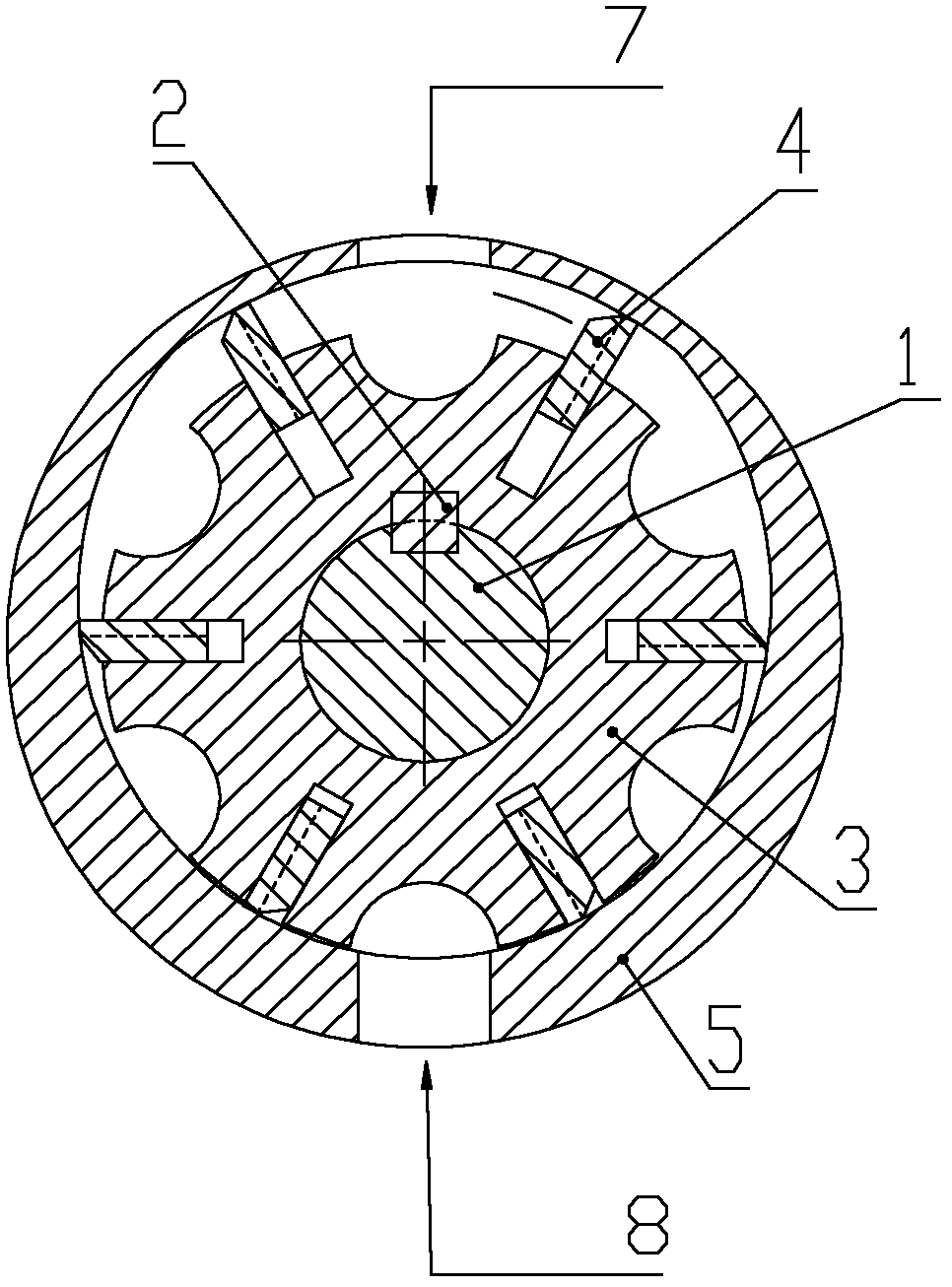

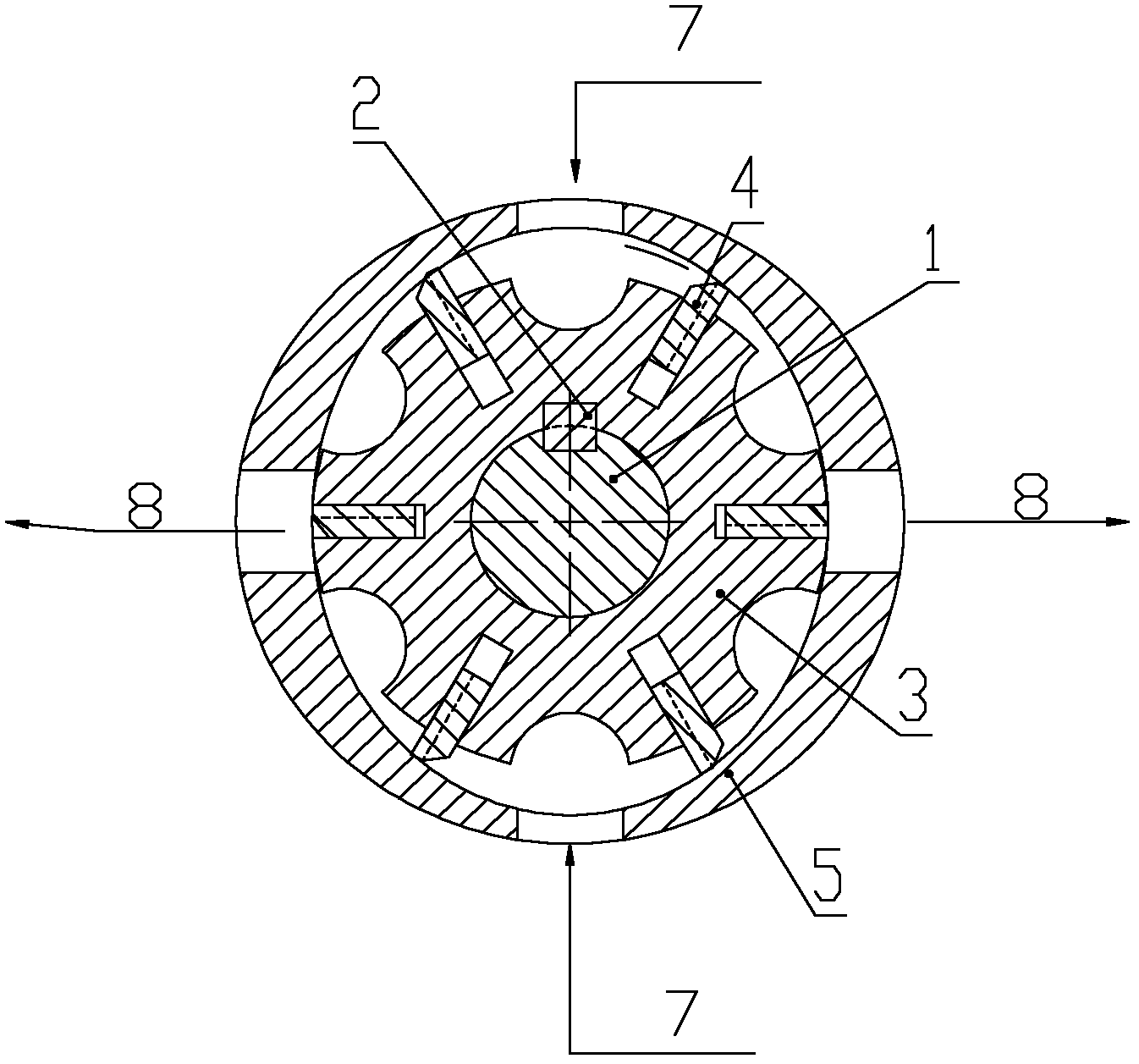

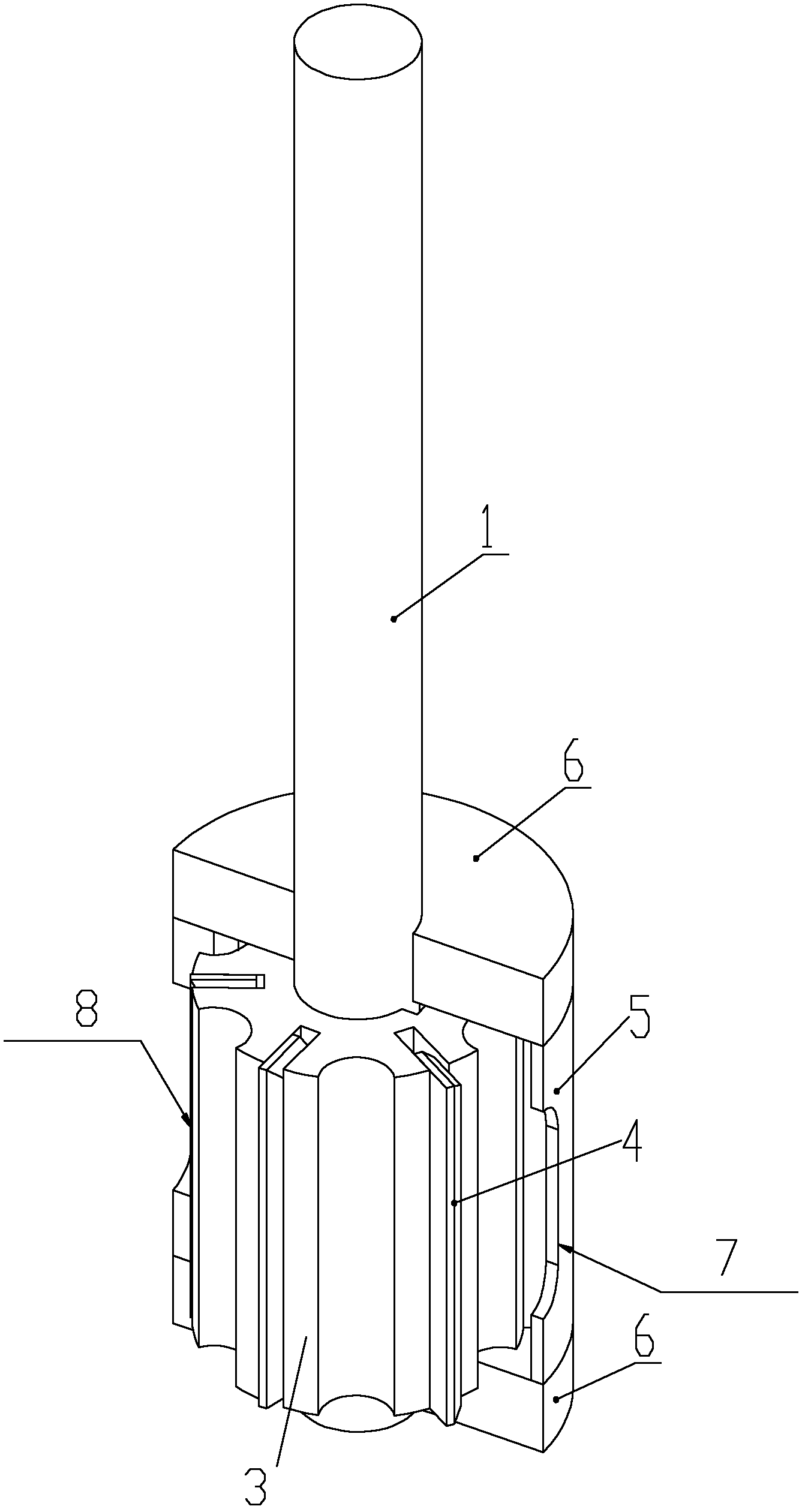

[0053] like Figure 4 to Figure 6 As shown, the present invention proposes a sliding vane pump, the sliding vane pump has a cylindrical pump casing 5, and the pump casing 5 is provided with: a drive shaft 1, a rotor 3 sleeved on the drive shaft, the rotor 3. The sliding vane 4 is fixedly connected with the drive shaft 1 through the connecting key 2 and is arranged on the rotor 3. The sliding vane 4 is in contact with the inner cavity of the pump casing 5, and the end of the pump casing 5 is provided with There is an end cover, and the sliding vane pump also has a sliding vane pump suction port 70 and a sliding vane pump discharge port 80, and the sliding vane pump suction port 70 and / or the sliding vane pump discharge port 80 are located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com