Three-way valve improved by utilizing air-condition four-way valve, hot-water air-conditioning system and air conditioner

An air-conditioning system and a four-way valve technology are applied in the fields of waste heat utilization systems of air-conditioning systems and hot-water air-conditioning systems, which can solve the problems of poor commutation performance and high cost of multiple solenoid valves, improve reliability, avoid refrigerant leakage, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

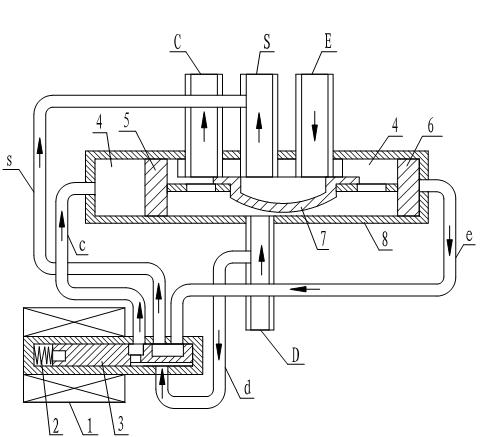

[0039] see diagram 2-1 , Figure 2-2 , Figure 3-1 and Figure 3-2 , on the basis of the structure of the original four-way valve, the pipe S is removed, the pipe S is closed with the tube root 6-8-1 of the valve body 8, and becomes a part of the valve body 6-8, the outlet end s of the capillary s -1 is the connection end with the suction pipe of the air conditioner compressor, the D pipe is the refrigerant inlet pipe, and the refrigerant outlet pipes are only the C pipe and the E pipe, so it becomes a three-way valve with one inlet and two outlets. In other words, on the basis of the structure of the original four-way valve, no S pipe is made, and the outlet end s-1 of the capillary s is connected to the suction pipe of the air-conditioning compressor. Through the above improvements, the original four-way valve becomes an electromagnetic three-way valve, which can be used as a solenoid valve in an air conditioner, or used as a solenoid valve in a hot water air conditionin...

Embodiment 2

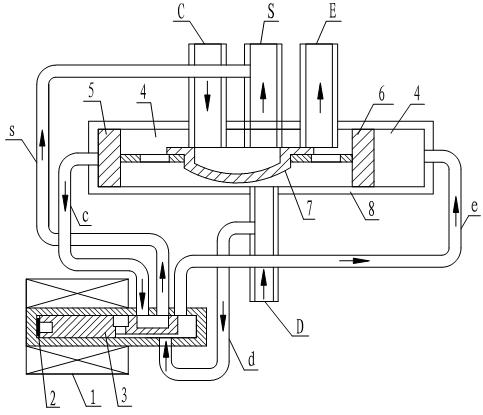

[0041] The S tube of the existing four-way valve can be retained and sealed by welding, or connected with a screw cap and a seal, so that the S tube is closed, and the outlet end s-1 of the capillary tube s is connected to the suction tube of the air conditioner compressor. connection end. Although the S tube is retained like this, because it is closed, the refrigerant cannot flow out. Similarly, the D pipe is the refrigerant inlet pipe, and the refrigerant outlet pipe is still only the C pipe and the E pipe, thus becoming a three-way valve with one inlet and two outlets.

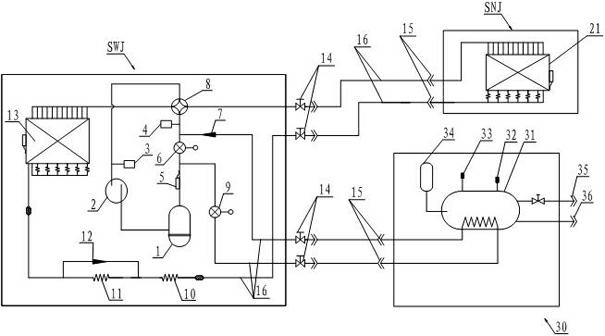

[0042] see Figure 4 , which is a system diagram of the application of the improved three-way valve 6 of the four-way valve in hot water air conditioning. The hot water air conditioning system includes a compressor 1, a four-way valve 8, a condenser 13, an evaporator 21, a water heater module 30, a plurality of one-way valves, capillary tubes, a four-way valve improved three-way valve 6, and a refrigerant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com