Flange catcher

A catcher and flange technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as flange collisions of submarine oil pipelines, potential safety hazards of divers, and low underwater visibility. Achieve the effect of improving safety factor and overall construction safety, shortening working time and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

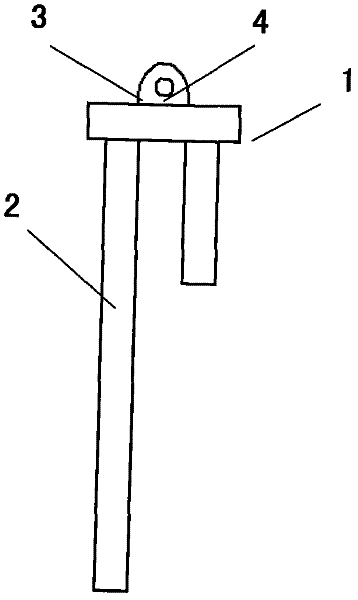

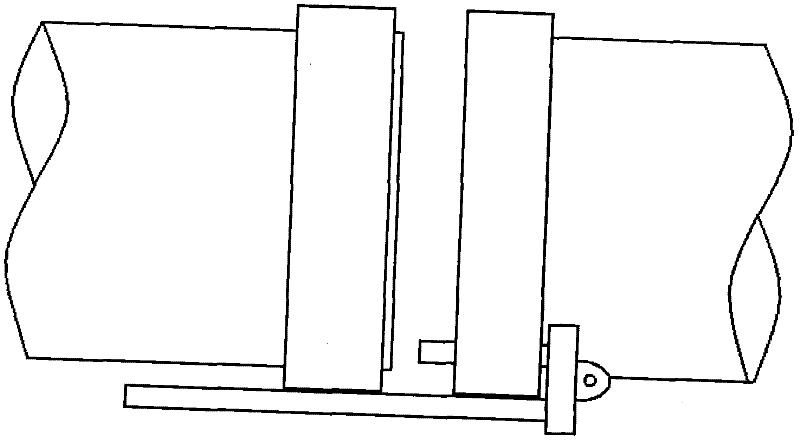

[0016] Such as figure 1 Shown, catcher 1 of the present invention adopts steel plate and two steel columns 2 of different lengths or two bolts of different lengths to be welded into an n-shaped body, and short steel columns 2 (or short bolts) are used to be inserted in the sea pipe method The flange catcher 1 is fixed in the blue bolt hole, and a lifting lug 3 is vertically welded on the steel plate surface at the upper end of the η-shaped body. The lifting lug 3 is made of steel plate, and a hole 4 is provided on the lifting lug 3 for dismounting from the flange. Flange catch1. In actual application, a pair of flange catchers are used each time, which are respectively installed in the bolt holes at the 5:00 and 7:00 positions of the flange.

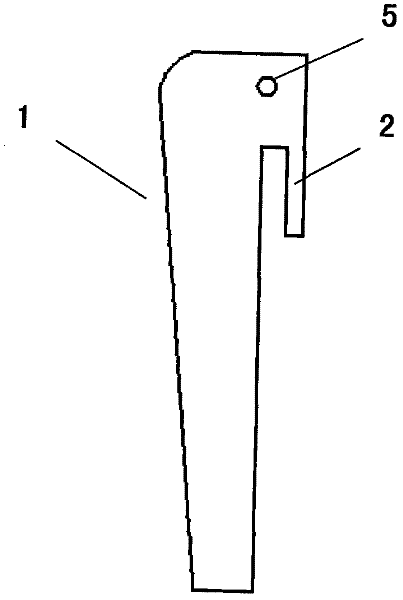

[0017] Such as figure 2 As shown, another embodiment of the catcher 1 of the present invention: the catcher 1 is an L-shaped body, and a hole 5 is arranged on the L-shaped catcher. The main body of the L-shaped body is a steel plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com