Intelligent heater utilizing superheat degree of industrial extraction steam

An industrial steam extraction and heater technology, which is applied to feed water heaters, lighting and heating equipment, preheating, etc., can solve the problems of superheated steam overheating, mismatching heating parameters, and poor energy loss, etc., to improve Feed water temperature, saving boiler coal consumption, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

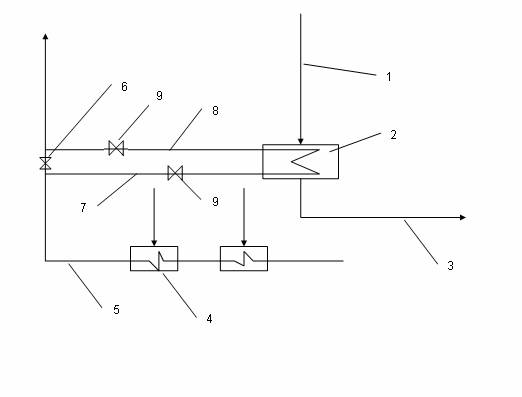

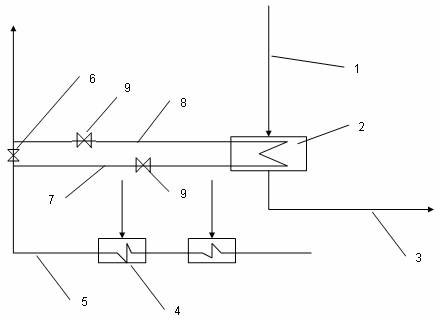

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises the intelligent heater 2 that is provided with extraction heat supply pipeline 1 and extraction steam outlet pipe 3, is connected with cold diversion feedwater inlet pipe 7 and hot diversion feedwater outlet pipe 8 on described intelligent heater 2, intelligent heater The water supply pipe 5 of 2 is provided with an intelligent flow distribution valve 6, and the intelligent heater 2 is connected in parallel with the intelligent flow distribution valve 6 on the water supply pipe 5; Valve 9; several high-pressure heaters 4 are installed on the water supply pipe 5, and the intelligent heater 2 is installed on the water supply pipe 5 where the outlet of the high-pressure heater 4 is located.

[0016] The smart heater 2 is connected with a cold split feed water inlet pipe 7, a hot split feed water outlet pipe 8, and an extraction steam outlet pipe 3 for heating users. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com