Gas stove

A gas furnace and gas burner technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problem that the main body of the burner is difficult to disassemble, and achieve the effect of maintaining the relative state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

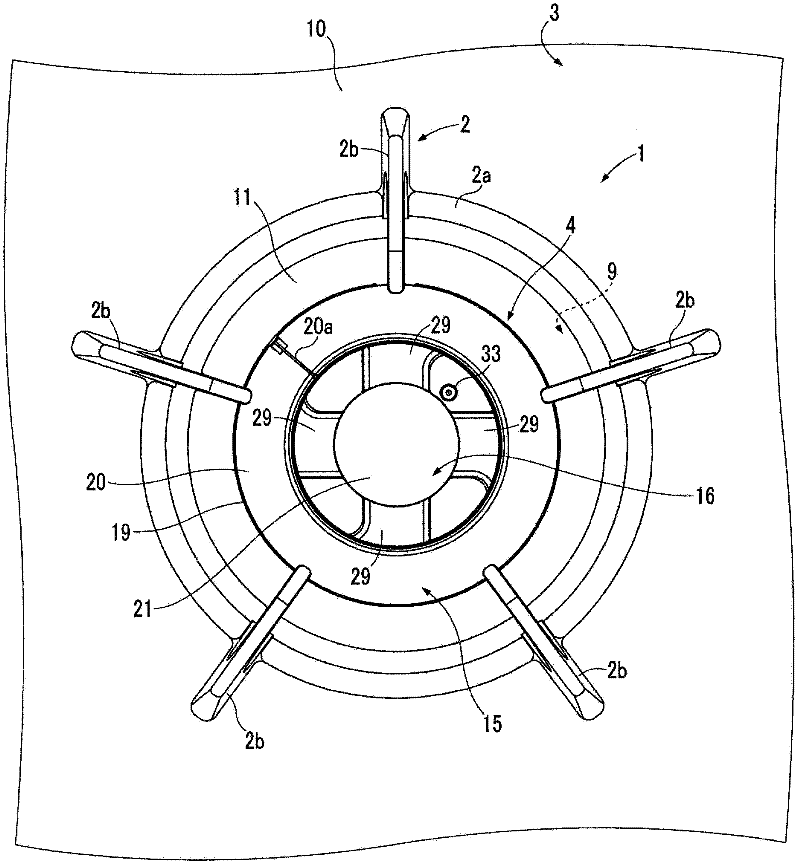

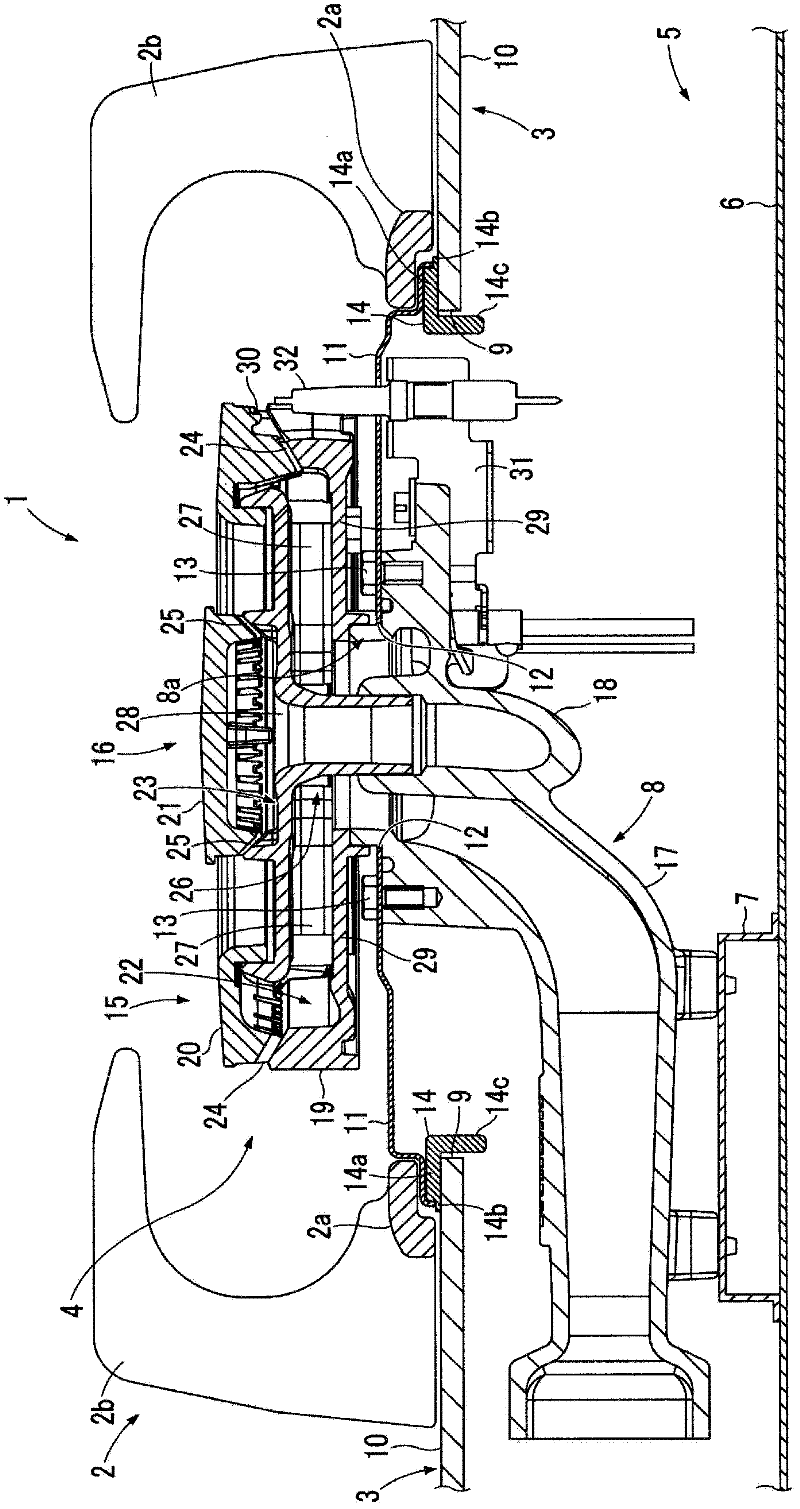

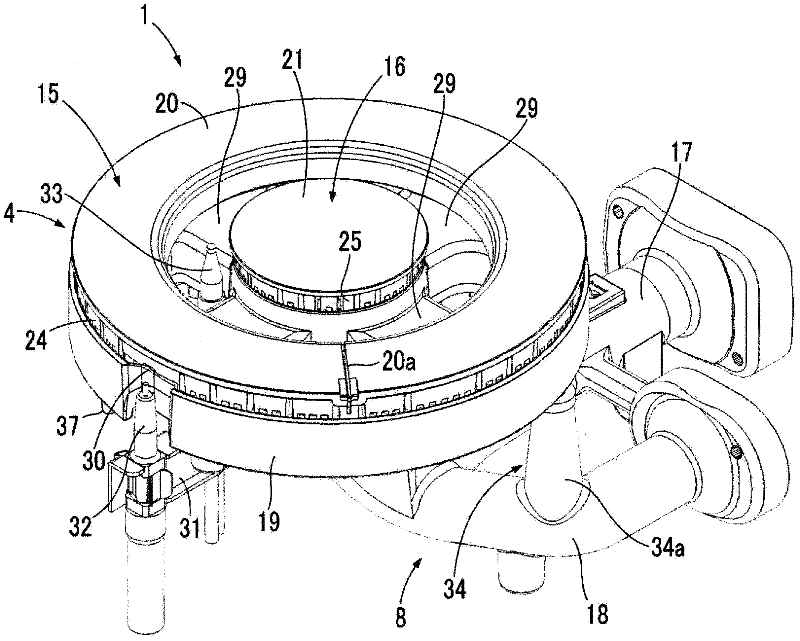

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings. The gas stove of this embodiment is such as figure 1 and figure 2 The gas burner 1 and the fire support 2 provided around the gas burner 1 are provided as the main part is shown.

[0026] The gas burner 1 includes a burner body 4 and a mixing tube 8 . The burner main body 4 is exposed on the upper surface of the panel 3 constituting a part of the structure of the gas stove. The mixing tube 8 is accommodated inside the stove main body 5 constituting the structure of other parts of the gas stove, and is coupled and fixed to the bottom plate 6 of the stove main body 5 via the base portion 7 . The downstream end 8a of the mixing tube 8 opens upward.

[0027] Such as figure 2 As shown, the panel 3 is arranged to cover the top of the stove main body 5 . The panel 3 is composed of a panel body 10 formed with a burner installation opening 9 whose inner diameter is larger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com