Energy dissipating water distributor of cross flow type cooling tower with hydrodynamic fan

A technology of hydrodynamic fans and cooling towers, applied in the field of cooling towers, can solve problems such as uneven water flow and environmental pollution, and achieve the effects of eliminating water splashes, avoiding splashes, and good anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

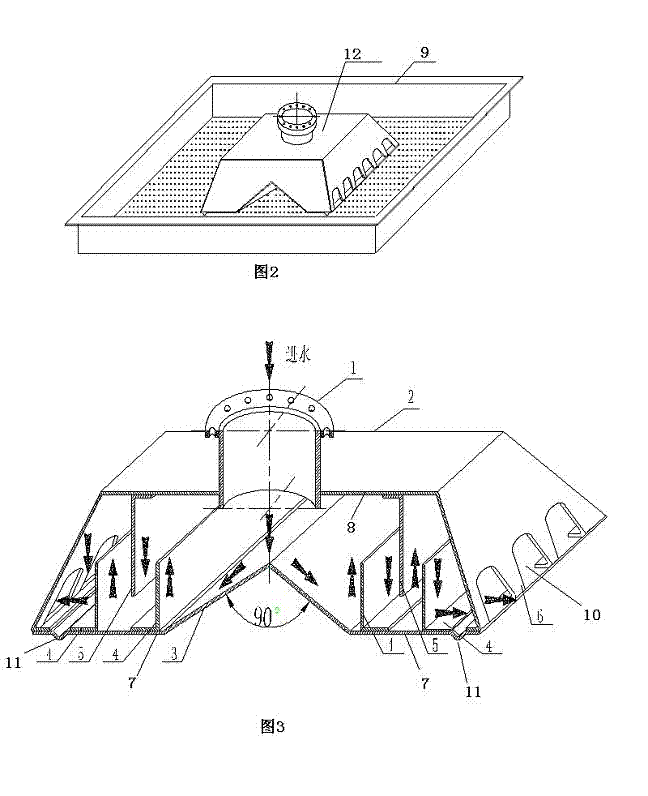

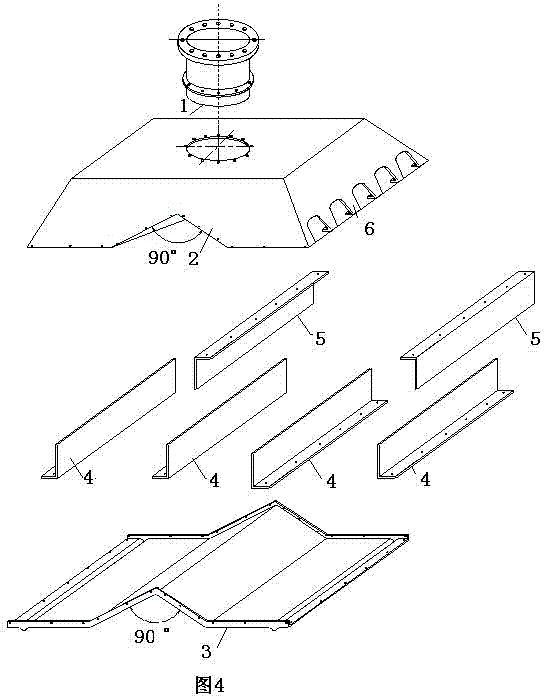

[0020] Such as image 3 , 4 shown.

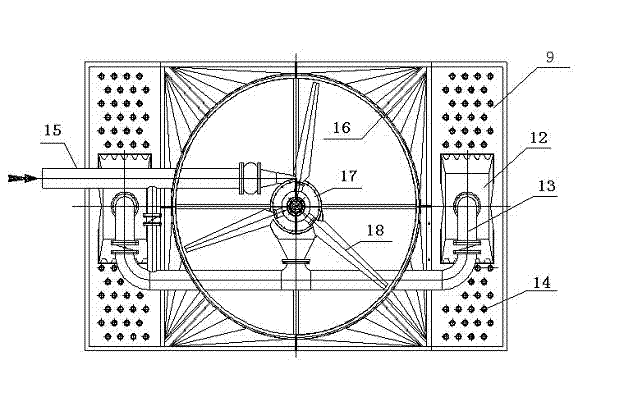

[0021] An energy dissipating water separator for a cooling tower of a cross-flow hydraulic fan can be entirely formed by pressing glass fiber reinforced plastics, and it is installed in the water distribution tank 9 of the cooling tower, such as figure 1 , 2 shown. The whole of the energy dissipating water separator is a quadrilateral frustum of cone structure, including the shell box 2, and the upper part of the shell box 2 is provided with a water inlet interface 1, which is characterized in that the bottom of the shell box 2 and the relative position of the water inlet interface 1 are provided. There is an inverted V-shaped central decompression splitter plate 3, the angle of the inverted V can be between 70-110 degrees, preferably 90 degrees, such as image 3 As shown, on the bottom plate 7 on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com