Thermal image device and shooting method for thermal image

A technology for shooting and infrared thermal imaging, which is applied in image communication, TV, color TV parts, etc., can solve the problems of slow shooting speed, easy omission, heavy workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

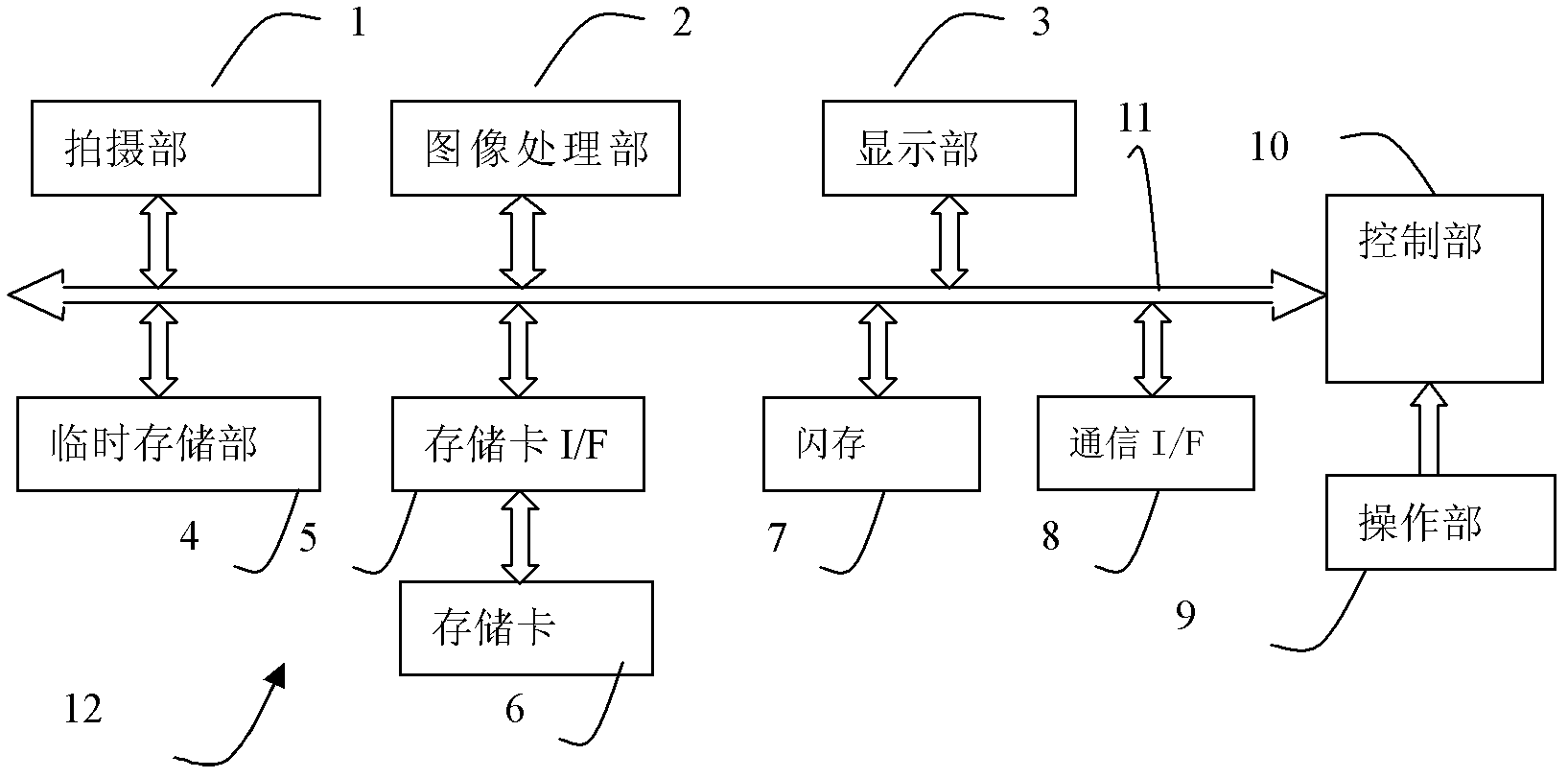

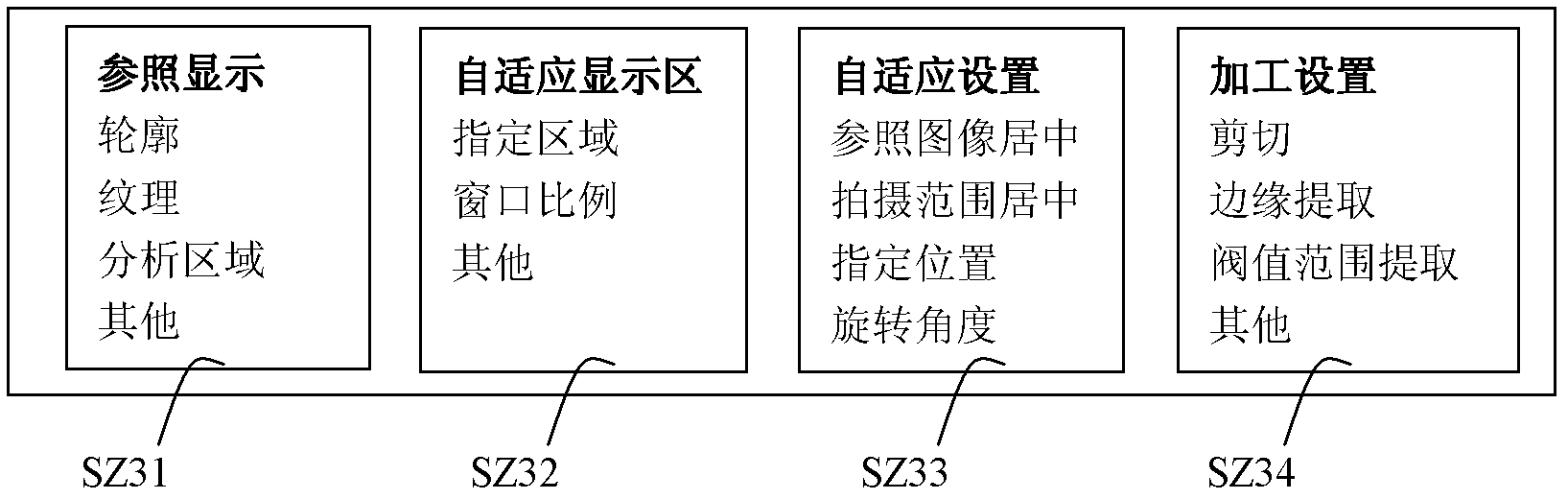

[0087] The difference from embodiment 1 is that this embodiment has the same figure 1 In the shown thermal imaging device 12 with the same structure, the flash memory 7 stores a control program for executing adaptive display of the reference image in the adaptive display area. Figure 16 It is a flowchart showing (adaptive display) reference mode processing control. Figure 17 Schematic diagram of the adaptive display effect after "centering the reference image" for the partial contour image. Figure 18 Schematic diagram of the adaptive display effect after "centering the reference range" of the local contour image. Figure 19 It is a schematic diagram of another implementation of the object information and morphological constitution data stored in the storage unit. Figure 20 It is a schematic diagram of another implementation of object information and multiple types of constituent data stored in the storage unit. Figure 21 A schematic diagram of a display interface for p...

Embodiment 3

[0106] Embodiment 3, this embodiment is with figure 1 In the thermal imaging device 12 shown with the same structure, different from the first embodiment, the flash memory 7 stores a control program for processing the determined object to obtain morphological composition data. This thermal image shooting method (processing reference mode, including processing mode and reference mode) will be described below, wherein the object designation part to be processed (control part 10) is used to designate the object to be processed; the image processing part (image processing Part 2), configured to perform at least one of processing of cutting, edge extraction, and threshold range extraction on the object to be processed; a storage portion (temporary storage portion 4, etc.), configured to store the morphological composition data obtained through processing; The reference composition determining unit (control unit 10 ) is used to determine the processed and obtained morphological comp...

Embodiment 4

[0130] This embodiment is with figure 1 In the thermal imaging device 12 with the same structure as shown, the flash memory 7 stores a control program for setting and recording related information of the configuration data. The control unit 10, the operation unit 9, and the display unit 3 are examples of the related information setting unit, which are used to set the setting information of at least one of the analysis area, object information, and indicator information corresponding to the form configuration data. 10 is used as an example of a setting recording unit to create an associated record between form configuration data and setting information.

[0131] For example, in step S303 of Embodiment 3, the morphological composition data obtained after processing is obtained. At this time, the subsequent reference mode shooting may not be performed temporarily, and the analysis area, prompt mark, and photographed area corresponding to the morphological composition data may be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com