Tester for measuring real stress-strain curve of plate material under unidirectional compression state

A technology of unidirectional compression and true stress, which is applied in the direction of measuring devices, testing the ductility of materials, analyzing materials, etc., can solve the problems that cannot truly reflect the mechanical properties of the sheet metal, and it is difficult to eliminate the friction of the end surface, so as to achieve good lubrication and contact small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

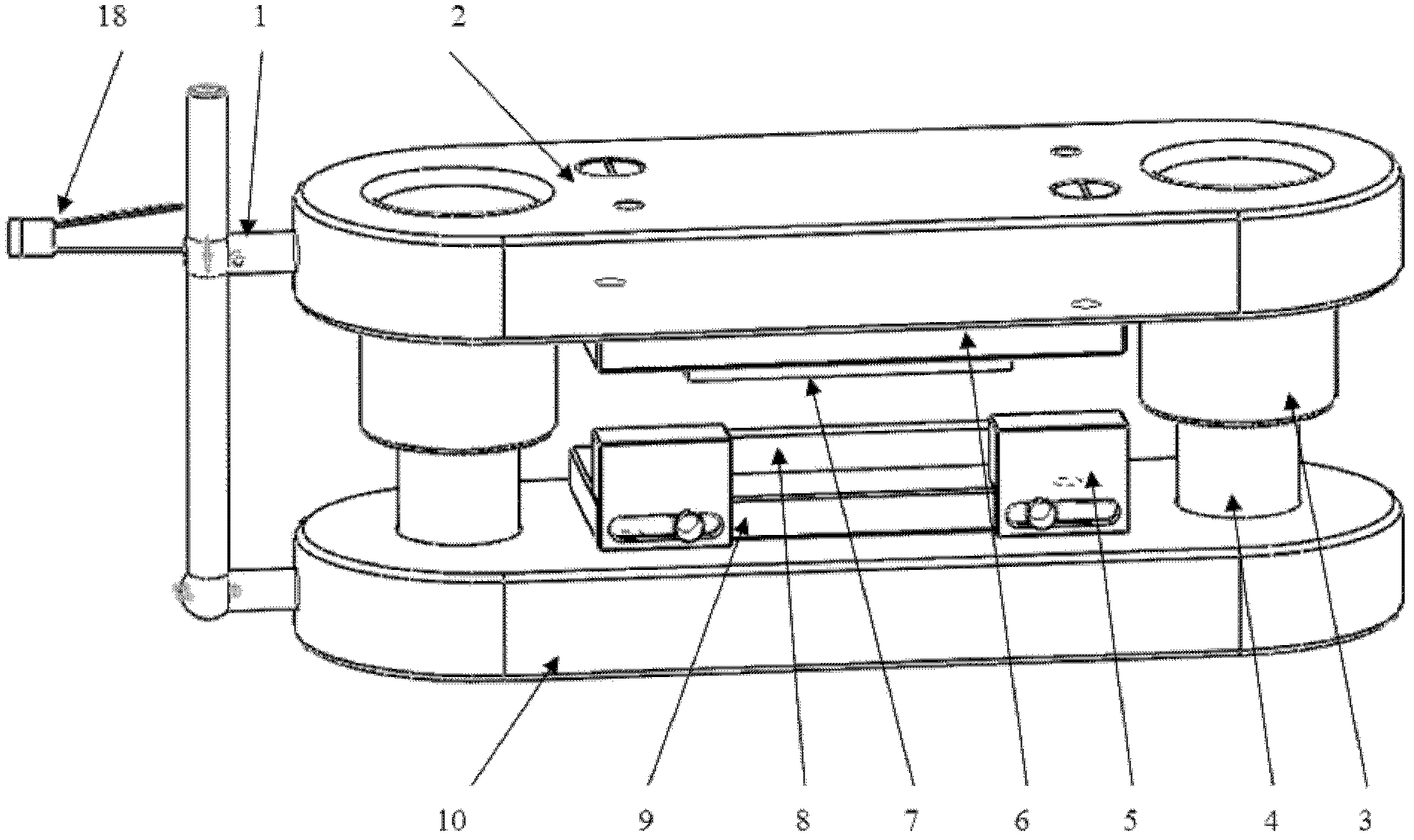

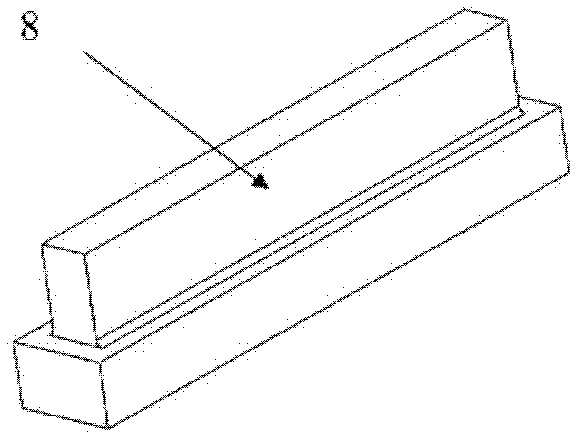

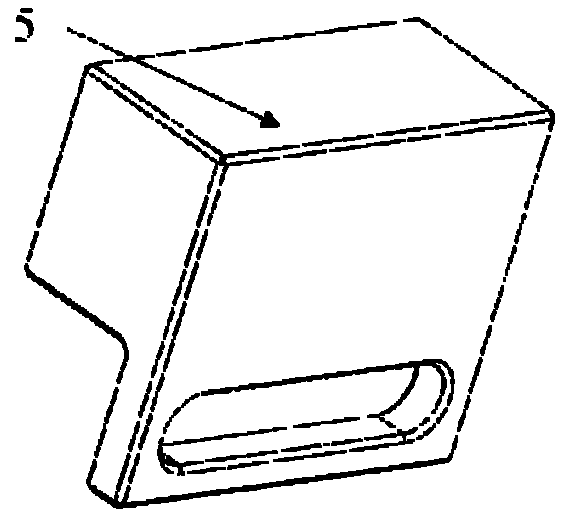

[0020] This example includes the upper mold base 2, the lower mold base 10, the upper insert 6, the lower insert 9, the upper punch 7, the lower punch 8, the guide post 4, the guide sleeve 3, the positioning block 5, the measuring frame 1 and the extension Count 18.

[0021] Adopt symmetrical guide post mold base, and A-type guide post guide sleeve, as shown in the drawings figure 1 Shown.

[0022] A guide sleeve 3 is provided at each end of the lower surface of the upper mold base 2, and a guide post 4 is provided at each end of the upper surface of the lower mold base 10, and the guide post 4 and the guide sleeve 3 are nested with each other After sliding connection, a space is formed between the lower surface of the upper mold base 2 and the upper surface of the lower mold base 10. The base of the upper punch 7 is located at the center of the lower surface of the upper die base 2; the upper surface of the base of the upper punch 7 is attached to the lower surface of the upper d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com