Touchable sensing matrix unit of co-constructed active array, active array and display

An active array and touch sensing technology, applied in the field of touch sensing matrix and sensing conduction matrix, can solve the problems of complex manufacturing process, low yield, and difficult to correct pressure sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

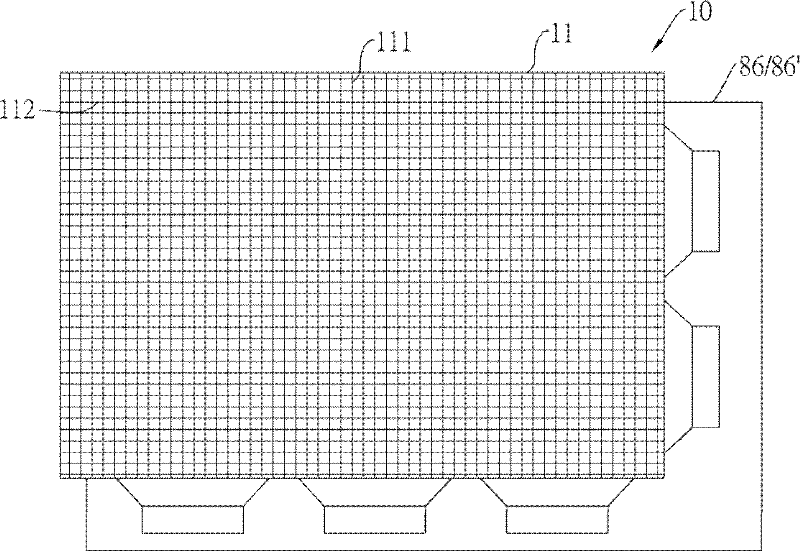

[0117] Example 1: Active Array TFT Liquid Crystal Display (1)

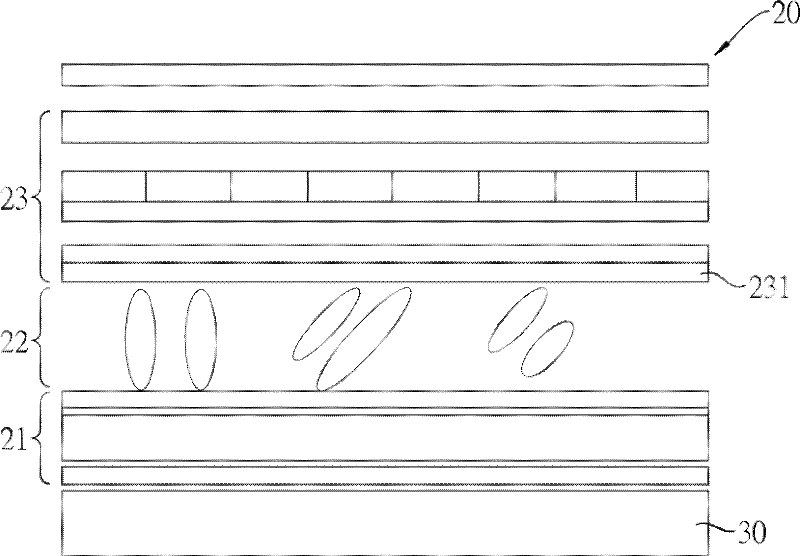

[0118] see figure 2 As shown, in this example, the active matrix TFT liquid crystal display or flat panel display can be a transmissive, reflective, or transflective TFT liquid crystal display or LTPS TFT liquid crystal display, or a microchip on a semiconductor chip. The microdisplay (Liquid Crystal on Silicon, LCoS) formed by the pixel array includes at least one upper substrate 23, which can be a color filter substrate, and the lower active array substrate 21 is a co-configuration touch sensing active array, with The liquid crystal layer 22 ; and the common electrode 231 is formed on the upper color filter substrate 23 . If it is a transmissive display, at least one backlight module 30 is further included under the display. Considering the shielding of the signal of the common electrode 231 to the signal of the capacitive touch sensing, the application of this example to the electromagnetic induction touch i...

example 2

[0119] Example 2: Active Array TFT Liquid Crystal Display (2)

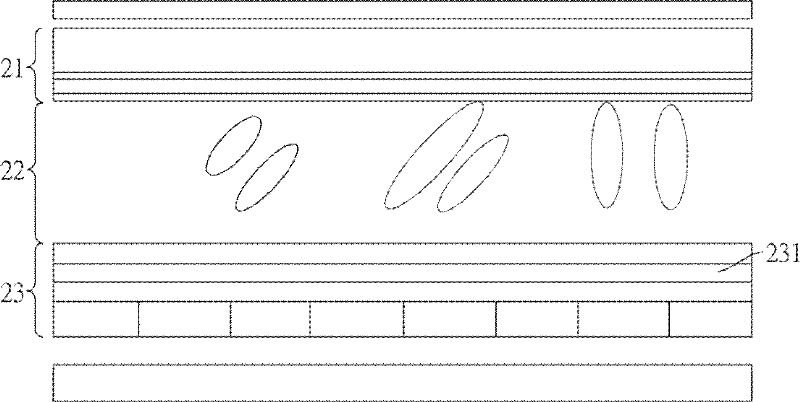

[0120] In this example, as image 3 As shown, the active array TFT liquid crystal display or flat panel display can be a transmissive TFT liquid crystal display or LTPS TFT liquid crystal display, which includes at least one upper active array substrate 21 which is a co-configured touch sensing active array and a lower color filter The substrate 23 interposes the liquid crystal layer 22 therebetween; and the first and second sensing conductive lines of the touch sensing matrix of the present invention are the data lines and scanning lines on the active array of the upper active array substrate 21 . According to the design of the co-configured touch sensing active array element, the multiple first sensing conductive lines and / or multiple second sensing conductive lines of the touch sensing matrix may be signal lines, reading lines, or bias lines, Or the control line, or part of the pixel circuit, or part of the au...

example 3

[0122] Example 3: The active matrix TFT display or flat panel display in this example is roughly the same as in Example 1, see Figure 5 As shown, it is a fringe field switching wide viewing angle (Fringe Field Switching Wide Viewing Angle) TFT liquid crystal display, which at least includes a lower active array substrate 21, an upper substrate 23' and a polarizer 24, and a liquid crystal molecule is interposed therebetween Layer 22 (LC molecule layer) is a negative type liquid crystal (ΔN=Ne-No<0) arranged horizontally; wherein the lower active array substrate 21 includes a first substrate 211, a pixel electrode layer 212 (pixel layer), a common Electrode layer 213 (common electrode layer).

[0123] The above-mentioned common electrode layer 213 and pixel electrode layer 212 are both arranged on the same side of the first substrate 211, and its structure is designed such that the fringe electric field is Figure 6 As shown in the common electrode layer 213 of the upper subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com