Three-speed temperature controlled power switch

A power switch and medium temperature technology, applied in the direction of thermal switch components, etc., can solve the problem that temperature control materials cannot respond quickly to temperature changes and deformation, and achieve the effect of rapid and accurate response, fast speed and stable structural state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

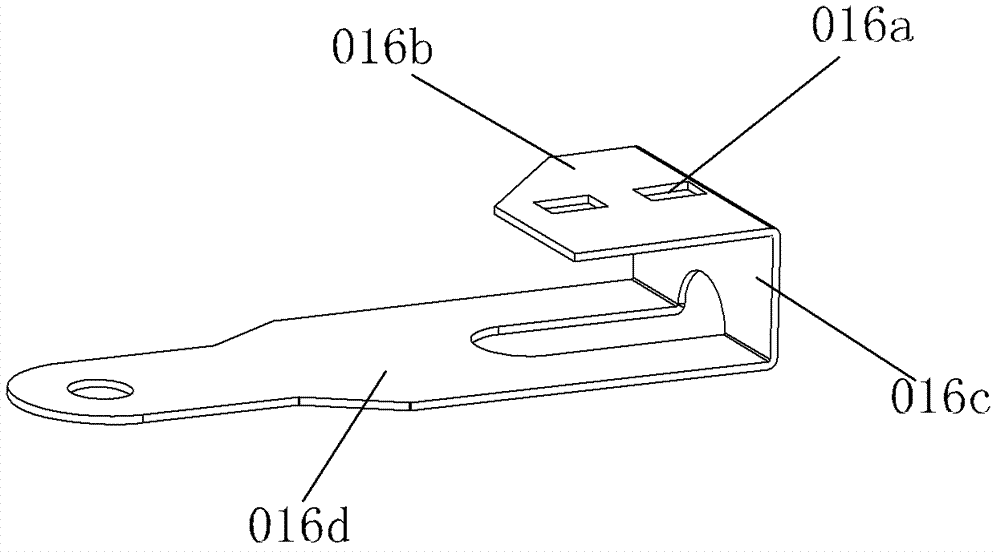

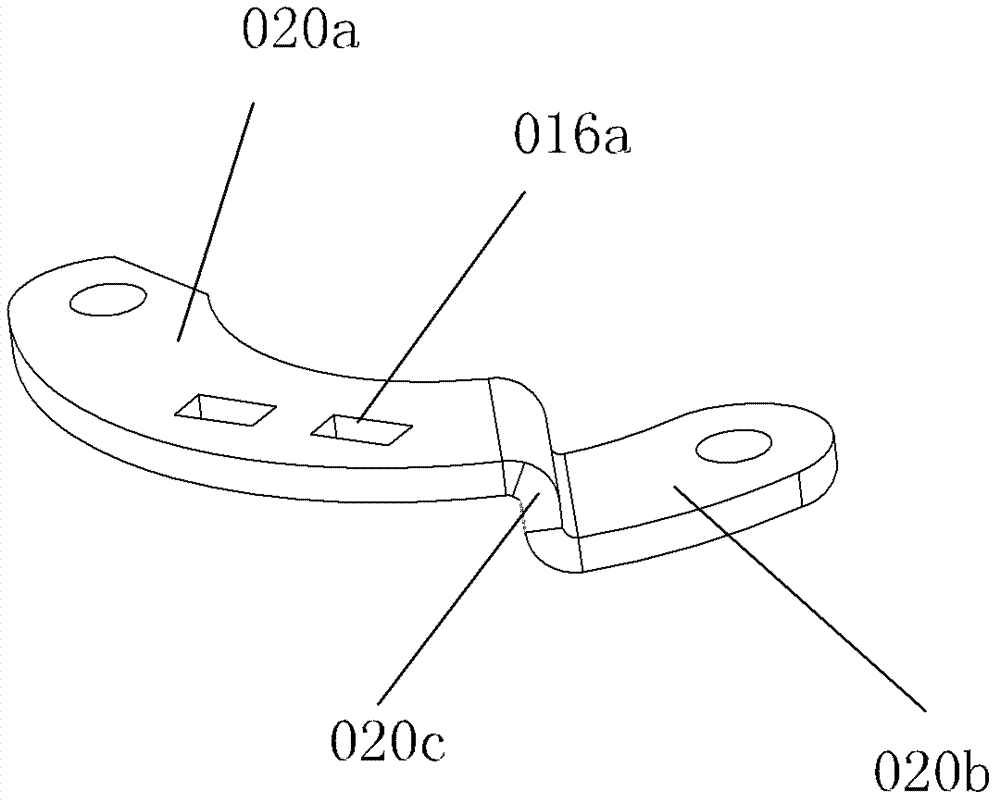

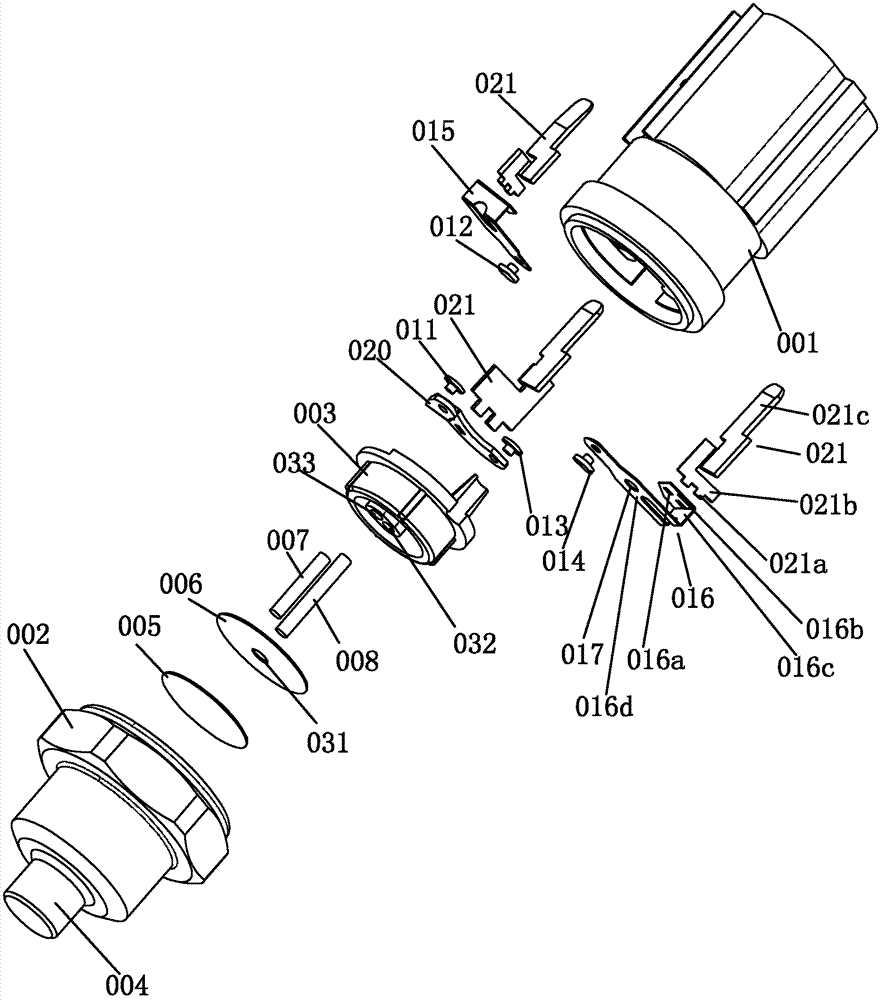

[0050] The transmission device of embodiment 1 includes a medium-temperature bimetallic strip 005, a high-temperature bimetallic strip 006, a first push rod 008, a second push rod 007, a fixed contact piece 020, a first movable contact piece 015, and a second movable contact piece 016. Such as Figure 4 As shown, the medium temperature bimetal 005 is placed on the first platform 009 at the bottom of the sensor housing 002, the high temperature bimetal 006 is placed on the second platform 010, the passive layer of the medium temperature bimetal 005 and the high temperature bimetal The passive layers of the metal sheet 006 are adjacent. Such as Image 6 , Figure 7 with Figure 8 As shown, the upper end surface of one end of the fixed contact 020 is provided with a first contact 011, and the upper end of the other end is provided with a second contact 013. The fixed contact 020 is bent so that there is a gap between the first contact 011 and the second contact 013. Height di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com