Crystal boat converter

A converter and positioning area technology, which is applied in semiconductor/solid-state device manufacturing, conveyor objects, electrical components, etc., can solve problems such as wafer fragmentation, wafer falling out of the wafer boat, collision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Since the present invention discloses a wafer boat converter, the manner of wafer boat conversion used therein has been understood by those with ordinary knowledge in the relevant technical field, so it will not be fully described in the following description. At the same time, the following diagrams are used to express the structural representations related to the features of the present invention, and they are not and need not be completely drawn according to the actual size, so they will be described first.

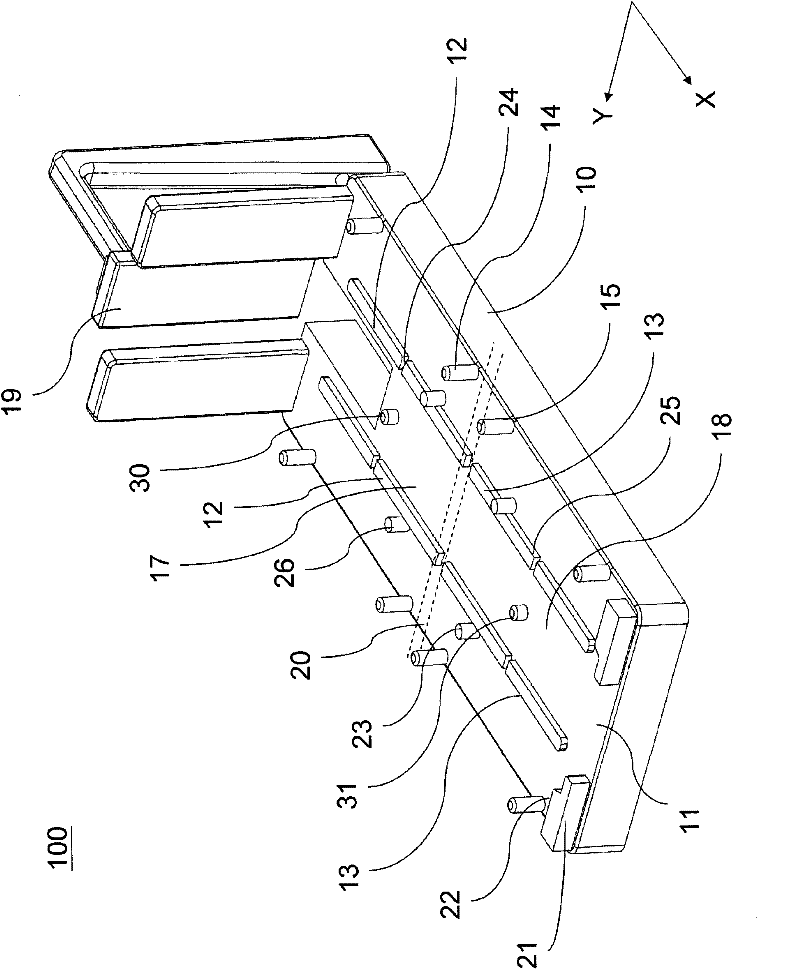

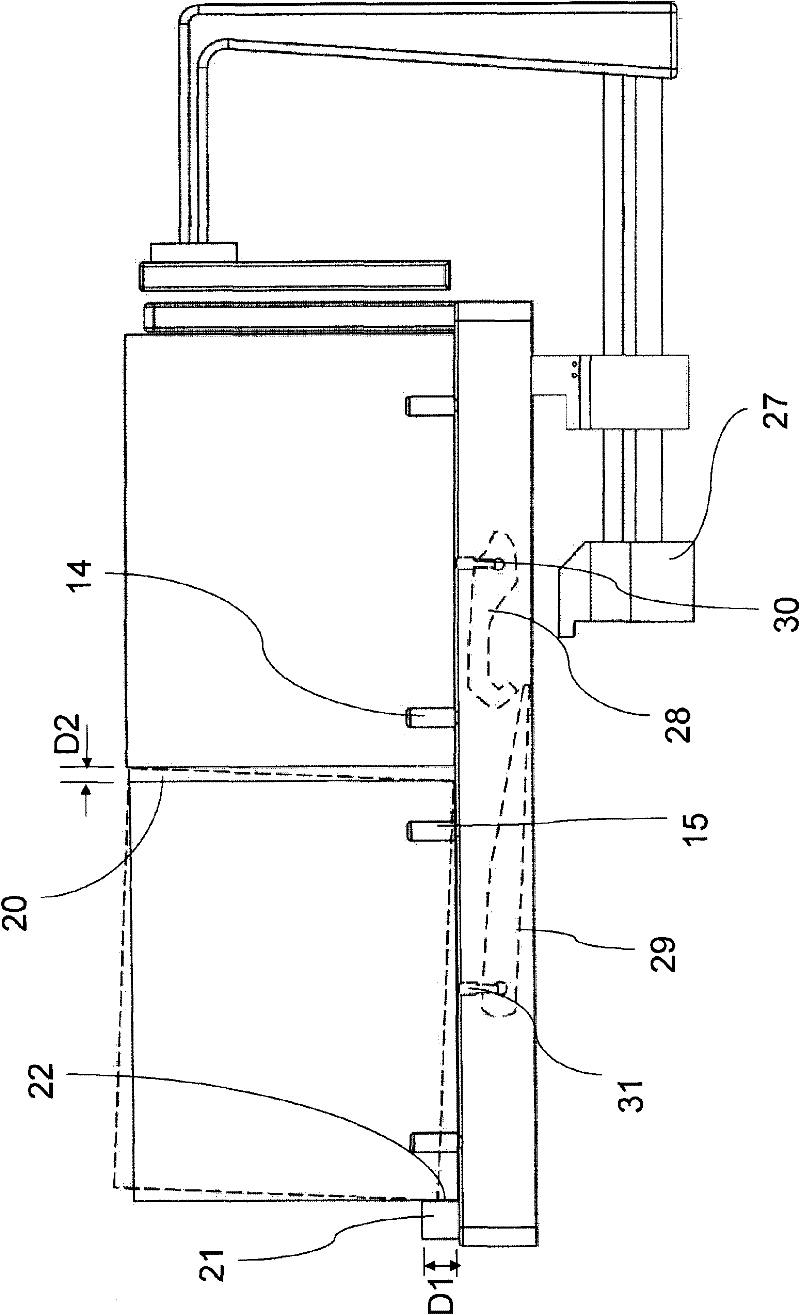

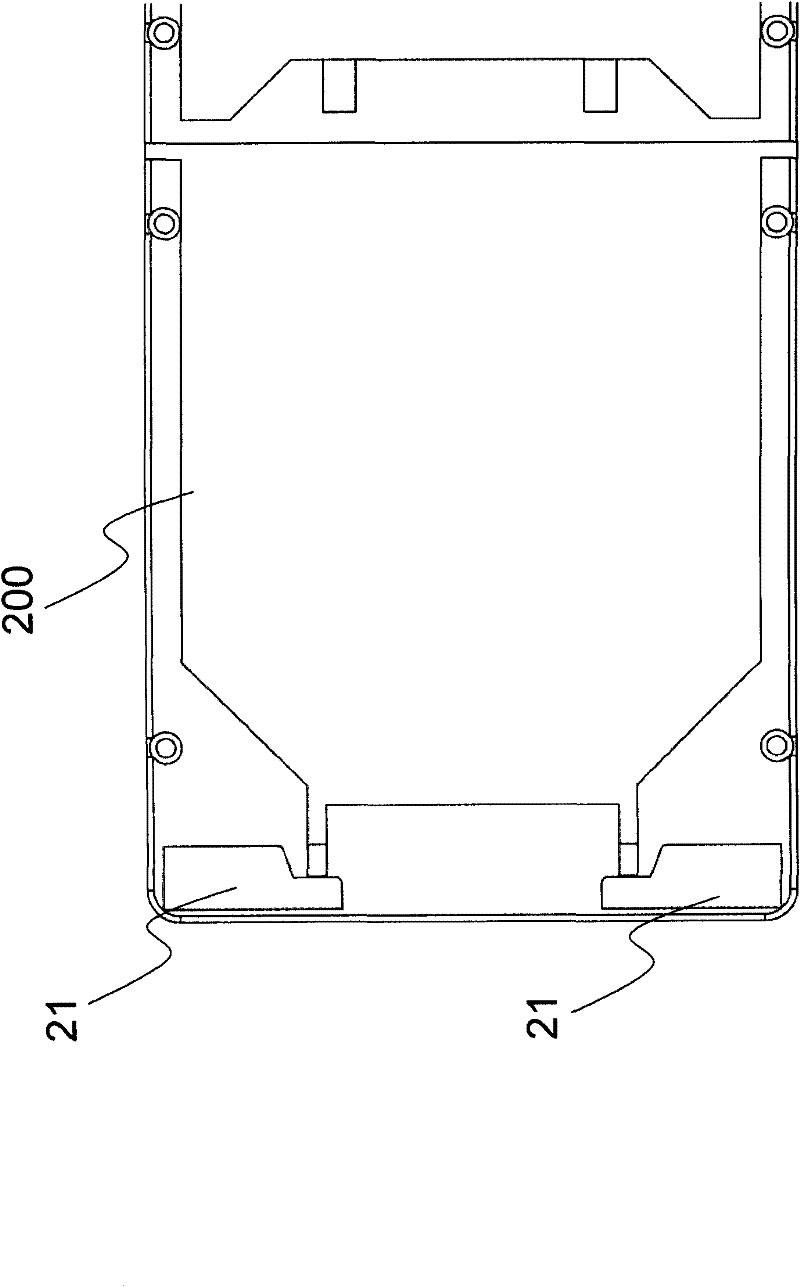

[0056] Please refer to Figure 1 to Figure 2 , is a first preferred embodiment proposed according to the present invention, which is a wafer converter 100 . This crystal boat converter 100 includes a base 10, the base 10 has a carrying plate 11, a first positioning guide rail 12, a second positioning guide rail 13, a first guiding device 14 and a second guiding device 15, and the carrying plate 11 is further A first positioning area 17 and a second positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com