Method for embedding multiple conductive terminals in circuit board, and conductive terminal

A technology of conductive terminals and circuit boards, applied in circuits, electrical components, circuit/collector parts, etc., can solve the problems of easy deformation of conductive terminals, many operation steps, and inability to meet the requirements of light and thin products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0036] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

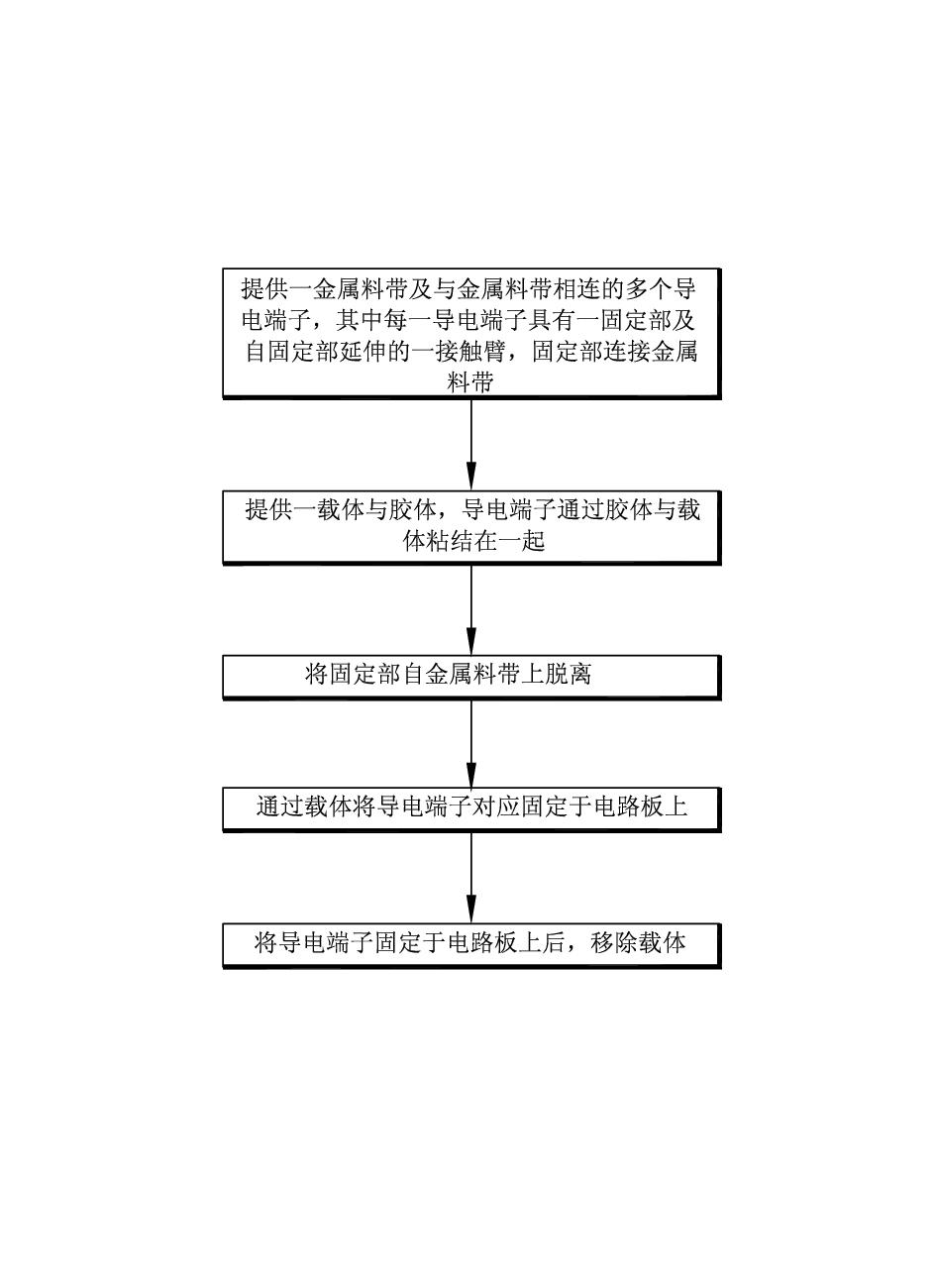

[0037] Please refer to figure 1 A schematic flow chart of the implementation of the present invention, a method for planting a plurality of conductive terminals on a circuit board includes the following steps.

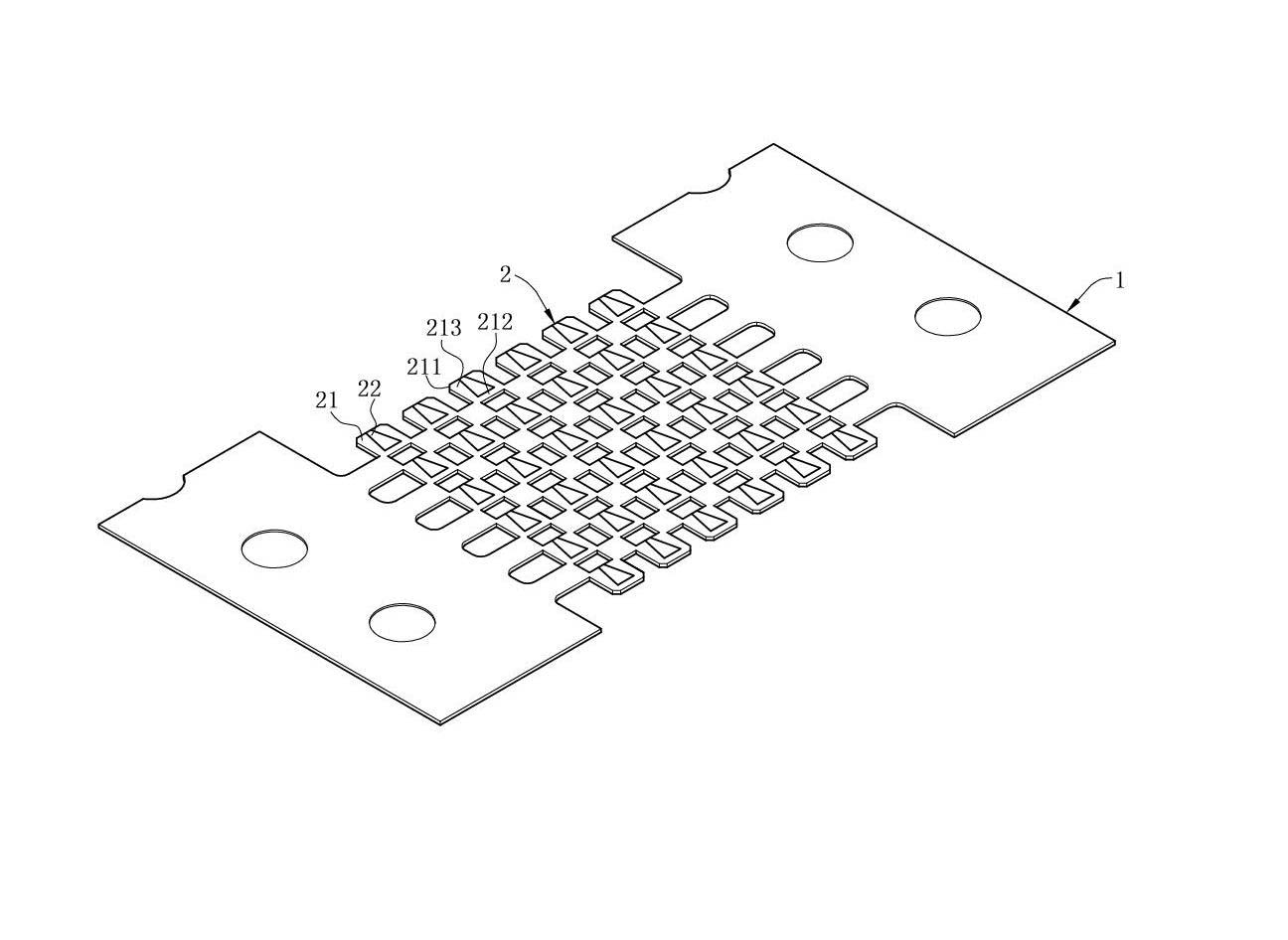

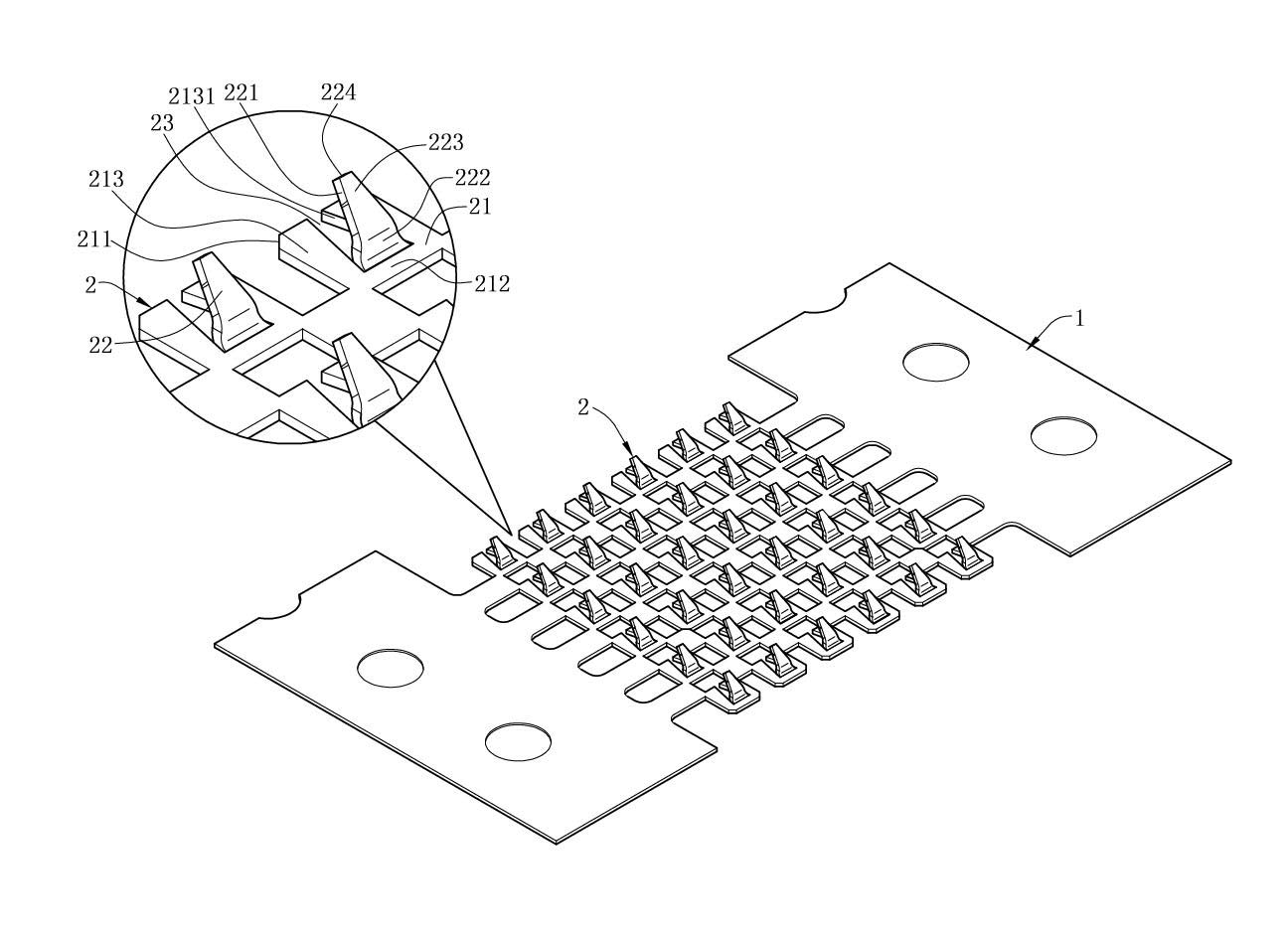

[0038] Please refer to image 3 , Step 1: providing a metal strip 1 and a plurality of conductive terminals 2 connected to the metal strip 1 .

[0039] A plurality of the conductive terminals 2 are arranged in a matrix, each of the conductive terminals 2 has a fixing portion 21 and a contact arm 22 extending from the fixing portion 21 .

[0040] The fixing portion 21 is flat and roughly rectangular, and each adjacent two sides form a chamfered side 211 (such as Figure 6 ), the fixing portion 21 is connected to the metal strip 1 at the chamfered edge 211. The fixing part 21 has a first plate 212 and two second plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com