Low-carbon energy-saving method for reducing temperature of livestock shed in summer

An economical, animal house technology, applied in animal husbandry, animal houses, applications, etc., can solve the problems of high construction and maintenance costs, poor thermal insulation effect, small ventilation area, etc., to achieve low system equipment costs and improve cooling. good effect, cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

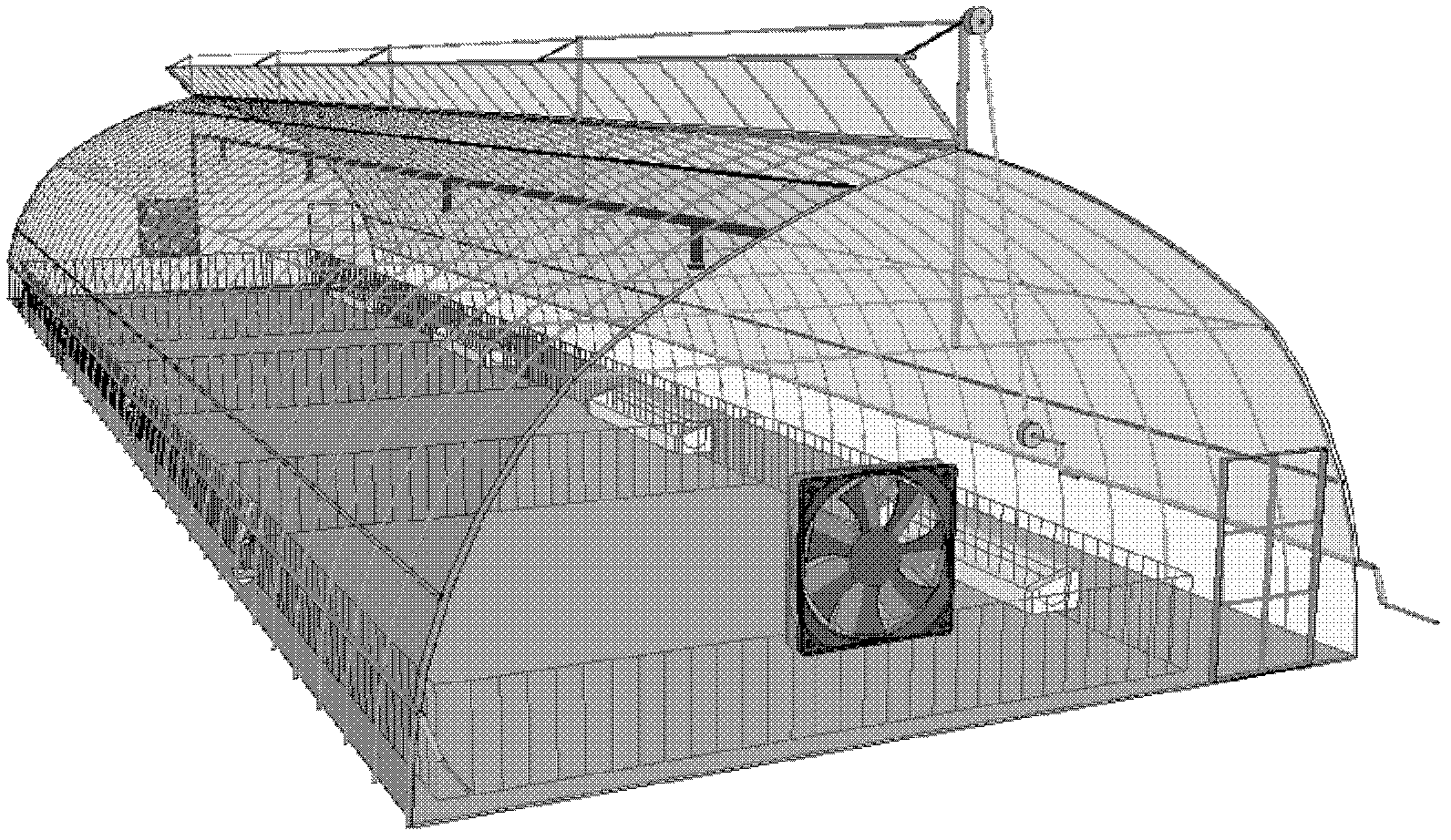

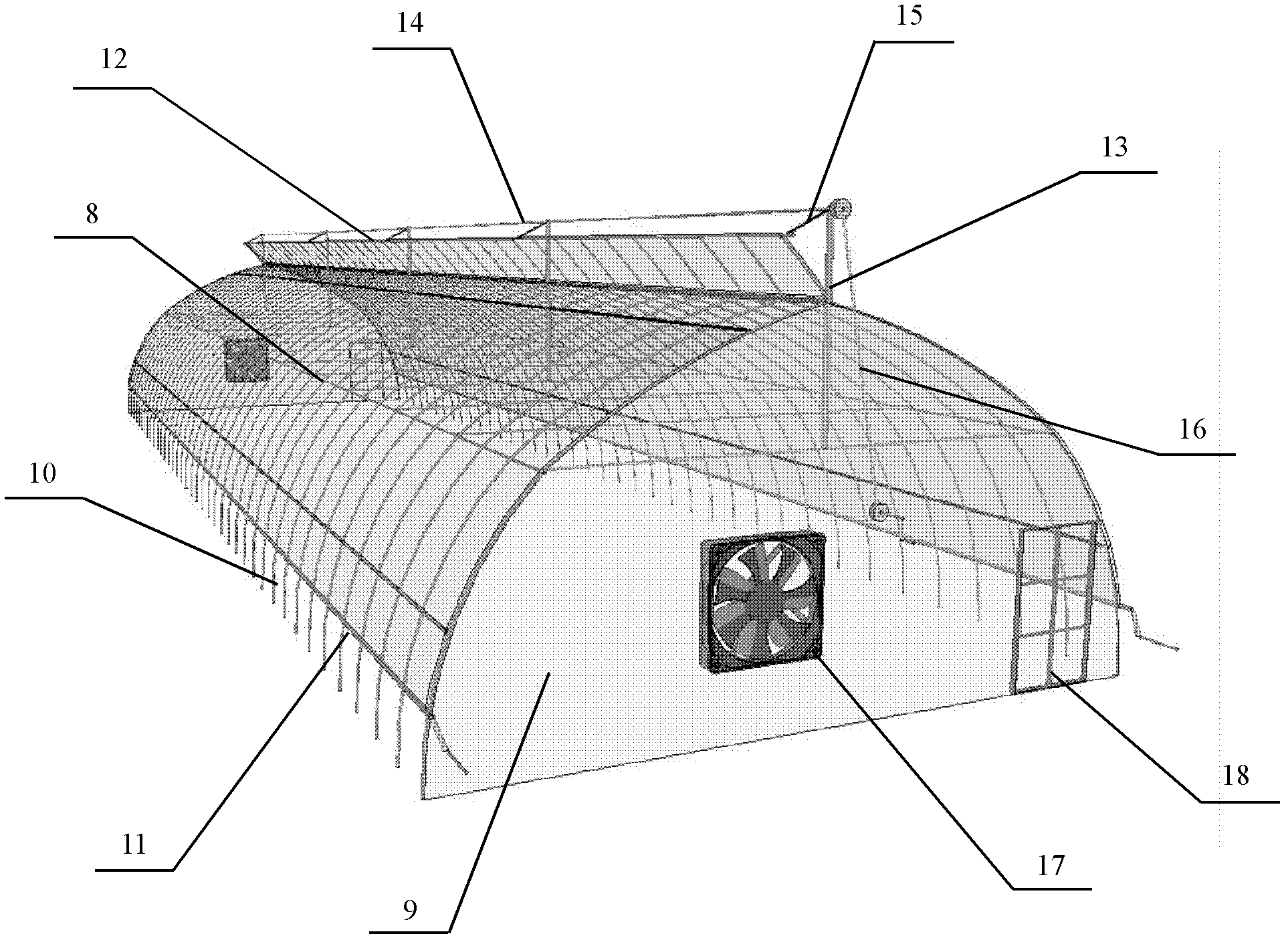

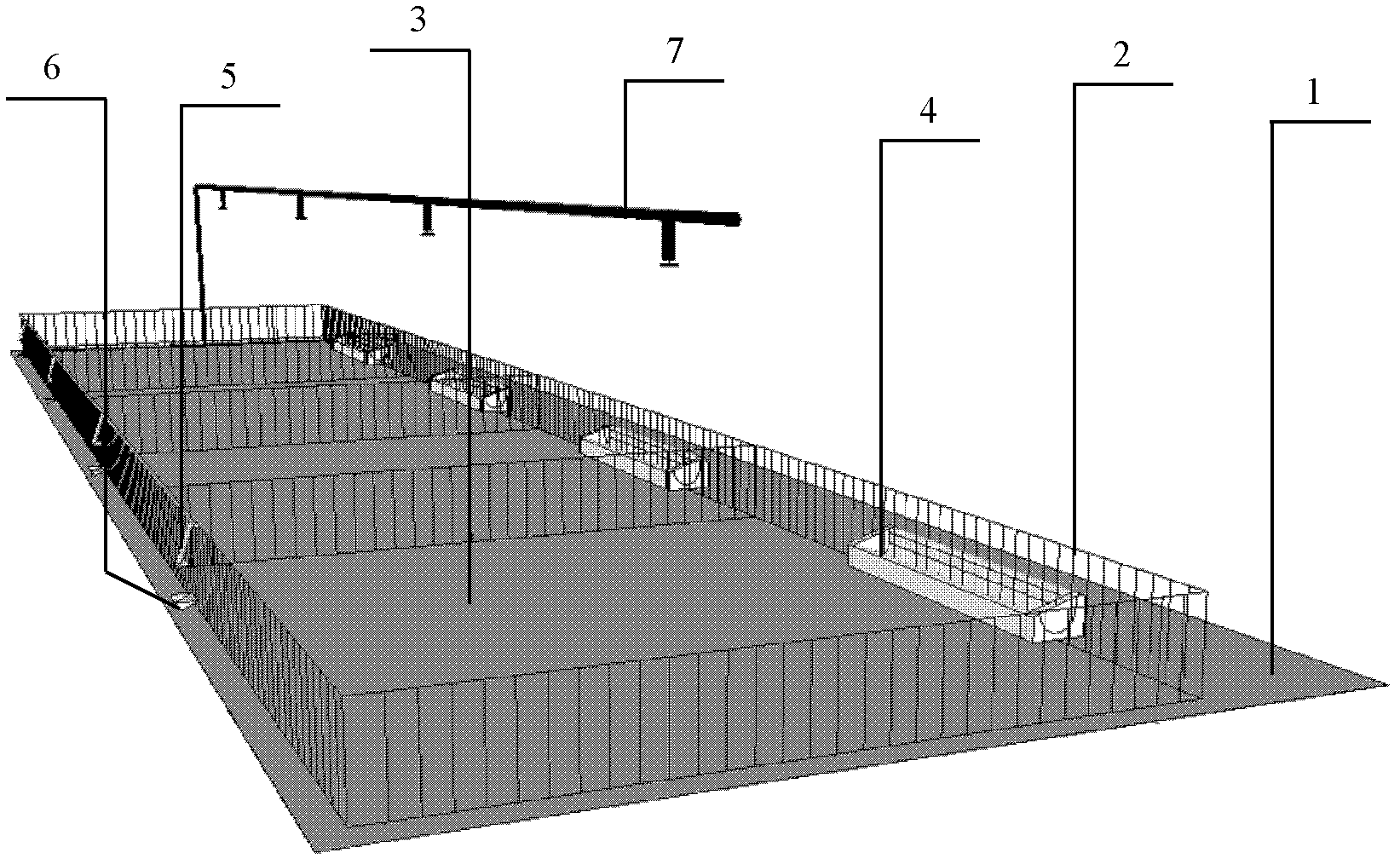

[0028] Below in conjunction with accompanying drawing the implementation details of the present invention are described as follows:

[0029] A low-carbon and energy-saving method for cooling livestock houses in summer, such as figure 1 As shown, the livestock house adopts a galvanized steel pipe greenhouse structure with a width greater than 8m and a height greater than 4m, and the surface of the livestock house is covered with a plastic light-transmitting film with waterproof and heat-insulating properties; figure 2 As shown, the roof (8) and gable wall (9) of the barn above 1.5m above the ground are covered with double-layer sunshade nets with a shading rate of 95% to shield strong light; since the barn is constructed with a greenhouse structure, the construction time is very short and the area 240㎡ 2 The barn usually takes 3-5 days to complete. The galvanized steel pipe used in the galvanized steel pipe greenhouse is a commercially available hot-dip galvanized steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com