Multifunctional spraying device and method for electrical equipment maintenance based on unmanned aerial vehicles

A technology for electric equipment and spraying devices, which is applied in the field of multifunctional spraying devices for electric equipment maintenance, can solve the problems of high cost and low comprehensive efficiency, and achieve the effects of low labor intensity, small operation risk and wide operation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

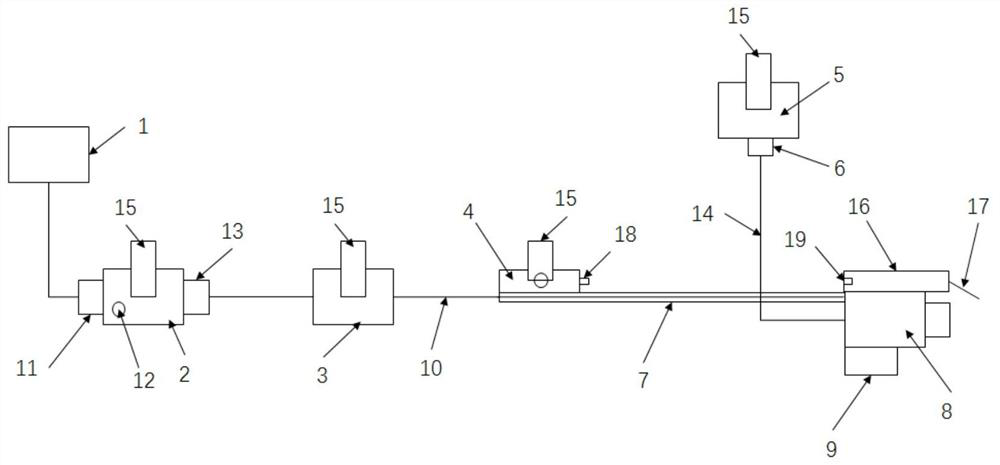

Image

Examples

Embodiment 1

[0047] PRTV spraying

[0048] 1) Install each component to the corresponding position of the drone;

[0049] 2) The miniature air compressor 1 takes out the miniature air compressor 1 after inflating the compressed gas cylinder 2 under high pressure;

[0050] 3) Add PRTV paint to material bottle 5;

[0051] 4) Start the drone to fly to the position to be sprayed and hover;

[0052] 5) Use the remote controller on the ground to control the controller on the UAV, adjust the pitch angle of the electric gimbal 4 so that the nozzle 8 is aligned with the position to be sprayed, and observe the laser sight shot through the camera, image transmission and display of the UAV during this process. to judge the aiming point;

[0053] 6) Control the controller on the drone through the remote controller on the ground, open the electromagnetic gas valve 3, and the high-pressure gas of the compressed gas cylinder 2 is transmitted to the nozzle 8 through the gas pipe 10, and the high-speed air...

Embodiment 2

[0057] liquid fuel fire

[0058] 1) Install each component to the corresponding position of the drone;

[0059] 2) The miniature air compressor 1 takes out the miniature air compressor 1 after inflating the compressed gas cylinder 2 under high pressure;

[0060] 3) adding liquid fuel to feed bottle 5;

[0061] 4) Start the UAV to fly to the position where it needs to spray fire to remove flammable foreign objects;

[0062] 5) Use the remote controller on the ground to control the controller on the UAV, adjust the pitch angle of the electric gimbal 4 so that the nozzle 8 is aligned with the position where the foreign matter needs to be removed by fire, and observe the laser aiming through the camera, image transmission and display of the UAV during this process Judging by the aiming point emitted by the device;

[0063] 6) Control the controller on the drone through the remote controller on the ground, open the electromagnetic gas valve 3, and the high-pressure gas of the co...

Embodiment 3

[0067] Cold Zinc Spraying

[0068] 1) Install each component to the corresponding position of the drone;

[0069] 2) The miniature air compressor 1 takes out the miniature air compressor 1 after inflating the compressed gas cylinder 2 under high pressure;

[0070] 3) Add cold zinc gas to feed bottle 5;

[0071] 4) Start the drone to fly to the position to be sprayed and hover;

[0072] 5) Use the remote controller on the ground to control the controller on the UAV, adjust the pitch angle of the electric gimbal 4 so that the nozzle 8 is aligned with the position to be sprayed, and observe the laser sight shot through the camera, image transmission and display of the UAV during this process. to judge the aiming point;

[0073] 6) Control the controller on the drone through the remote controller on the ground, open the electromagnetic gas valve 3, and the high-pressure gas of the compressed gas cylinder 2 is transmitted to the nozzle 8 through the gas pipe 10, and the high-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com