Powder metallurgy forming mold carrier with two point five or three point five lower palates

A technology of powder metallurgy and 2.5, which is applied in the field of powder forming hydraulic machine formwork, which can solve the problems of unfavorable market competition, time-consuming, and increased material consumption, and achieve the effects of improving market competitiveness, reducing production costs, and simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

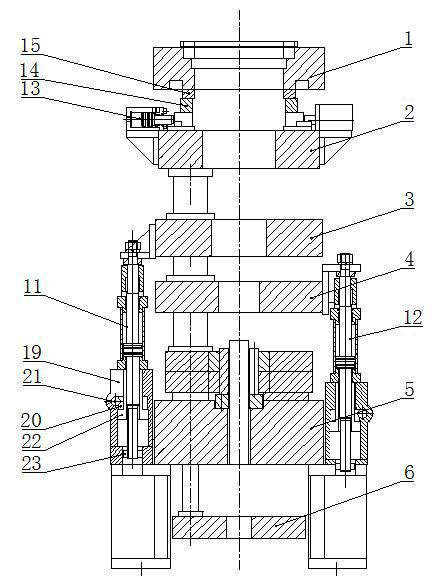

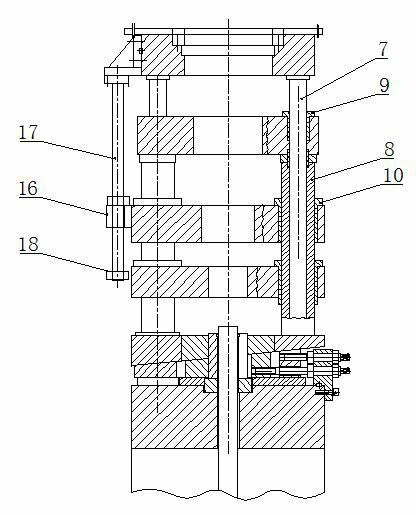

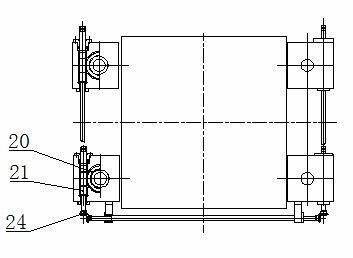

[0015] Such as figure 1 , 2 As shown, the lower formwork includes female formwork 1, upper fixed plate 2, floating plate I3, floating plate II4, lower fixed plate 5, lower formwork 6, lower guide column 7, support column 8, guide sleeve I9, guide sleeve II10, Floating cylinder 11, floating cylinder 12, side oil cylinder 13, block II14, block I15, limit seat 16, pull-off rod 17, limit nut I18, worm gear box 19, worm gear 20, worm 21, external thread adjustment Screw rod 22, limit nut II 23.

[0016] Above-mentioned lower formwork is provided with female template 1, upper fixed plate 2, floating plate, lower fixed plate 5 and lower template 6 successively from top to bottom, and floating plate has at least one layer. The lower 2.5 formwork adopts a female template, a floating plate and an upper fixed plate. The lower 3.5 formwork adopts a negative template, two floating plates and an upper fixed plate, and so on.

[0017] In the present embodiment, the lower formwork is a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com