Flux-cored wire for master cable energy forced shaping, and preparation and application method thereof

A technology of flux-cored welding wire and large line energy, applied in welding equipment, welding equipment, arc welding equipment, etc., to achieve the effects of strong adaptability, improved welding deposition efficiency, and less smoke and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The preparation method of flux among the present invention is as follows:

[0075] (1) prepare each component by the mass percentage of setting;

[0076] (2) drying each component, the drying temperature of each component is not more than 450°C, and the temperature is kept for 2 to 4 hours;

[0077] (3) 100% of each component is passed through an 80-mesh sieve, and then put into a mixer for uniform mixing, and the mixing time is not less than 35 minutes.

[0078] The prepared filler flux is immediately covered with the outsourcing steel strip in a dry and sealed state, and the sealing work is done during the handling process to avoid moisture.

[0079] The method further comprises the following molding step: adding the prepared filler flux into the container on the molding machine, then adding it to the steel strip to be shaped, and crimping and sealing the steel strip with the filler flux by rollers.

[0080] The gas-electric vertical welding flux-cored wire of the p...

Embodiment 1

[0083] In this implementation case, based on the total mass of the flux cored wire: C: 0.03% to 0.04% Wt, Si: 0.3% to 0.45% Wt, Mn: 1.3% to 1.6% Wt, Ni: 0.2% to 0.5% Wt, Mo: 0.2%~0.3%Wt, Ti: 0.05%~0.07%Wt, B: 0.003%~0.009%Wt, Mg: 0.01%~1.0%Wt, Al: ≤0.1%Wt; And Cu, V, Cr, Nd and other unavoidable metal impurities and S, P and other non-metallic impurities; the steel strip is made of flux cored wire special steel strip (SPCC) with C content not exceeding 0.07% and other impurities. The content of the slagging agent based on the total mass of the flux-cored wire is: potassium fluoride / sodium / lithium: 1.5%-4%Wt, fluorite: 1.2%-4%Wt, rutile: 1%-3.5%Wt. The amount of flux in the flux-cored wire accounts for 15% of the total mass of the wire.

Embodiment 2

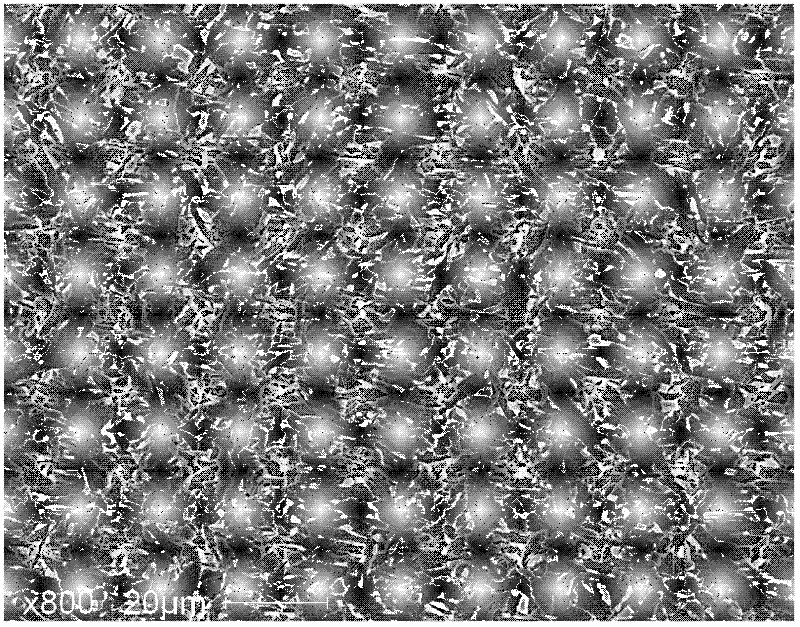

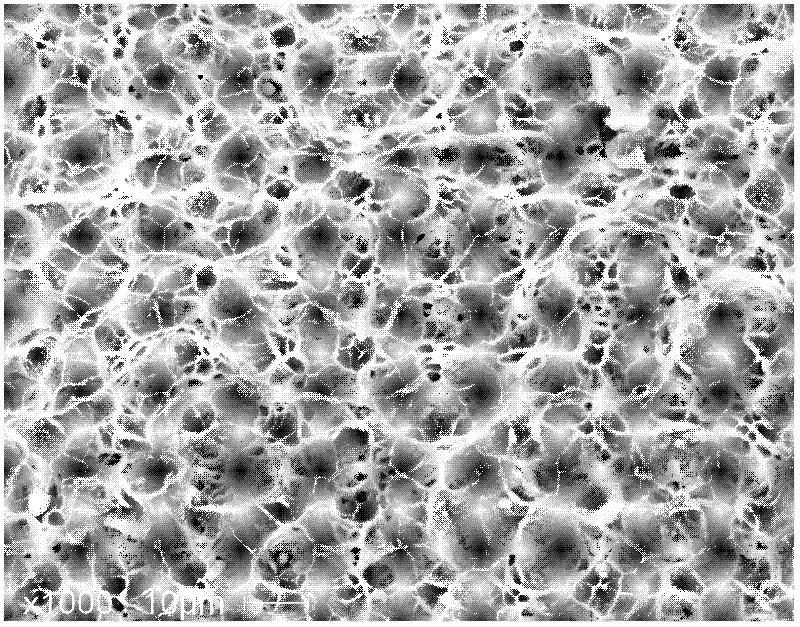

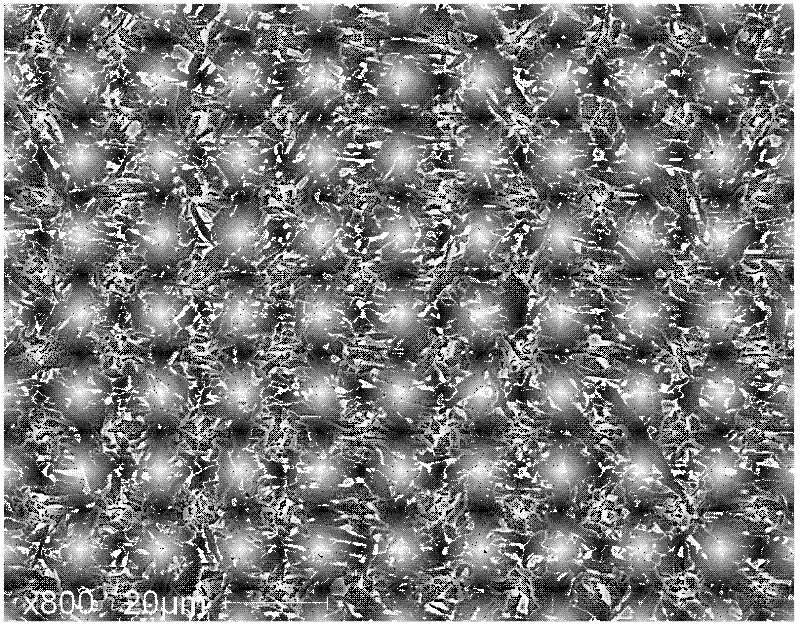

[0085] In this implementation case, based on the total mass of the flux cored wire: C: 0.035% to 0.045% Wt, Si: 0.35% to 0.5% Wt, Mn: 1.35% to 1.65% Wt, Ni: 0.2% to 0.45% Wt, Mo: 0.2%~0.25%Wt, Ti: 0.05%~0.065%Wt, B: 0.003%~0.008%Wt, Mg: 0.01%~0.8%Wt, Al: ≤0.1%Wt; And Cu, V, Cr, Nd and other unavoidable metal impurities and S, P and other non-metallic impurities; the steel strip is made of flux cored wire special steel strip (SPCC) with C content not exceeding 0.07% and other impurities. The content of the slagging agent based on the total mass of the flux-cored wire is: potassium fluoride / sodium / lithium: 1.5%-3.5%Wt, fluorite: 1.2%-6%Wt, rutile: 1.5%-3%Wt. The amount of flux in the flux-cored wire accounts for 21% of the total mass of the wire. attached figure 1 It is the SEM photo of the weld metal of embodiment 2, consisting of uniform acicular ferrite; figure 2 It is the SEM photo of the fracture of the impact sample of the weld at -20°C in Example 2, which is a dimple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com