Wood drying method

A technology of wood drying and drying method, which is applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of immature technology, poor timeliness, lagging behind the time, etc., and achieve the goal of improving drying quality and preventing internal cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

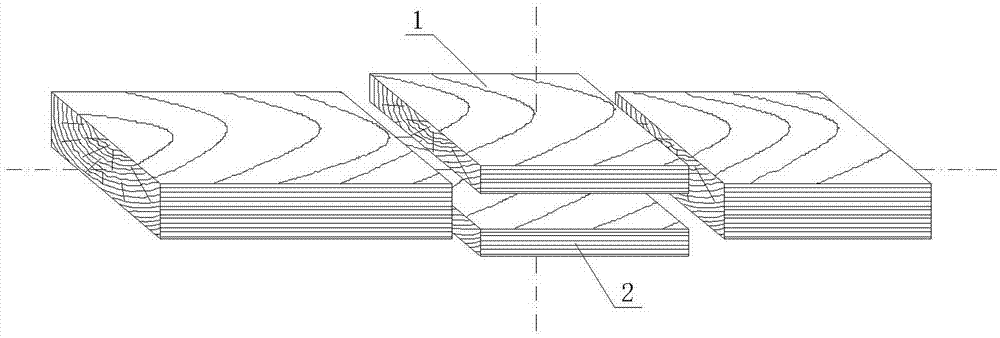

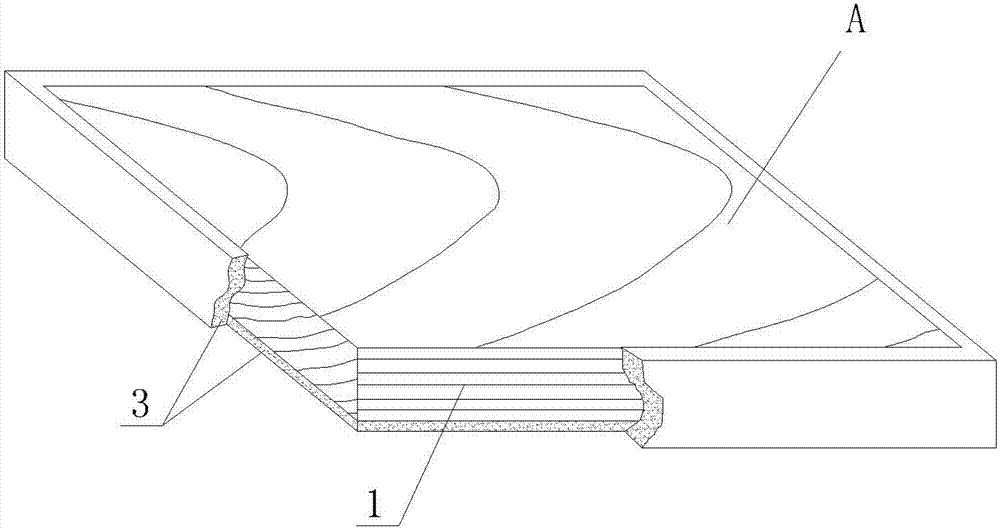

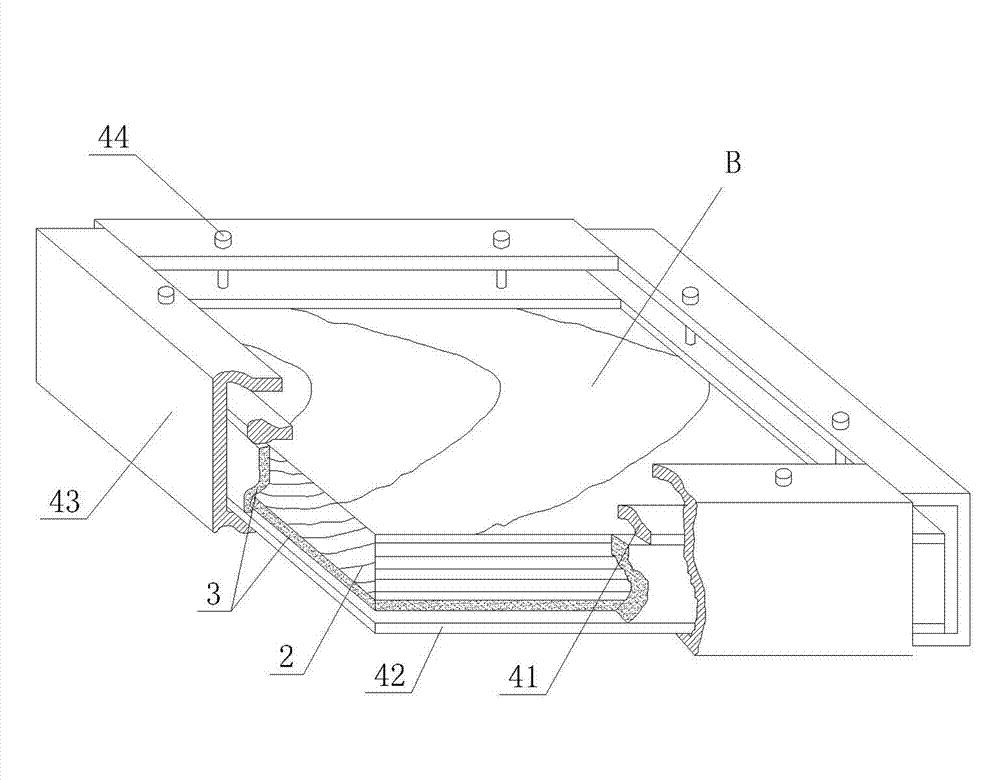

[0014] like Figure 1 to Figure 3 As shown, a wood drying method provided by the present invention is mainly a method for controlling the wood drying process through wood stress, comprising the following steps: a) Before wood drying: two pieces of wood are sawed from the dried wood that has never entered the drying kiln. A stress test piece, seal the five faces of one of the stress test pieces to form the first stress test piece 1, seal the same five faces of the other stress test piece, and then fix these five faces with a fixing sleeve to form the first stress test piece 1. Second stress test piece 2; b) Initial stage of wood drying: observe the curvature of the first stress test piece 1 at any time, and adjust the temperature and humidity of the drying medium according to its curvature; c) During and later wood drying: observe the curvature of the second stress test piece 1 at any time The curvature of the piece 2, combined with the curvature of the first stress test piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com