Defective recording element detecting apparatus and method, and image forming apparatus and method

一种记录元件、检测设备的技术,应用在电气元件、图像通信、印刷等方向,能够解决摆动或弯曲、图像读取光学系统摇摆等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0082]

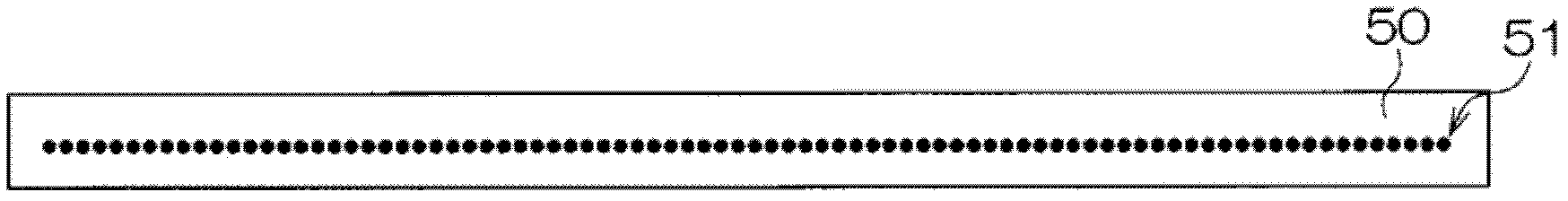

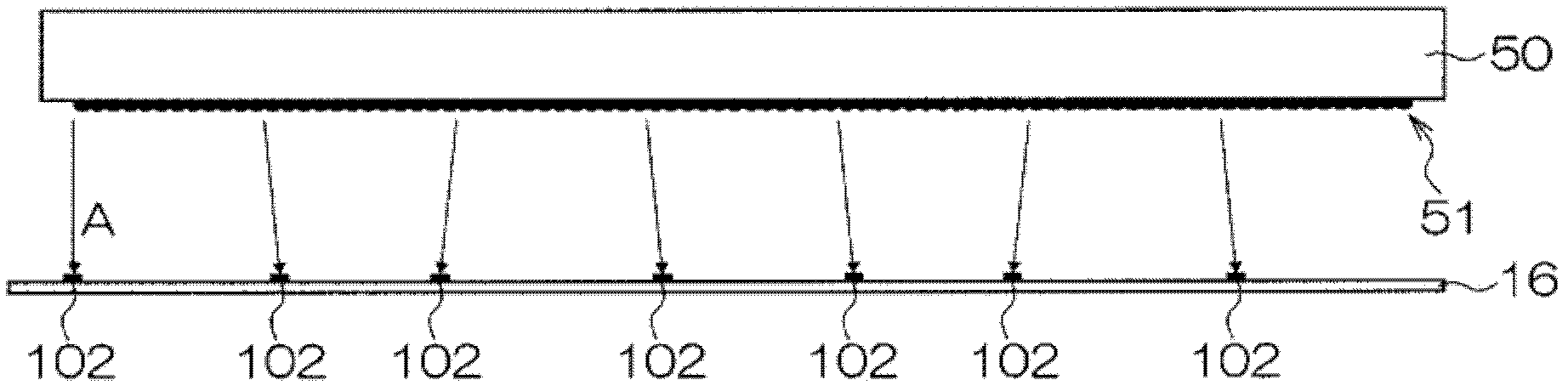

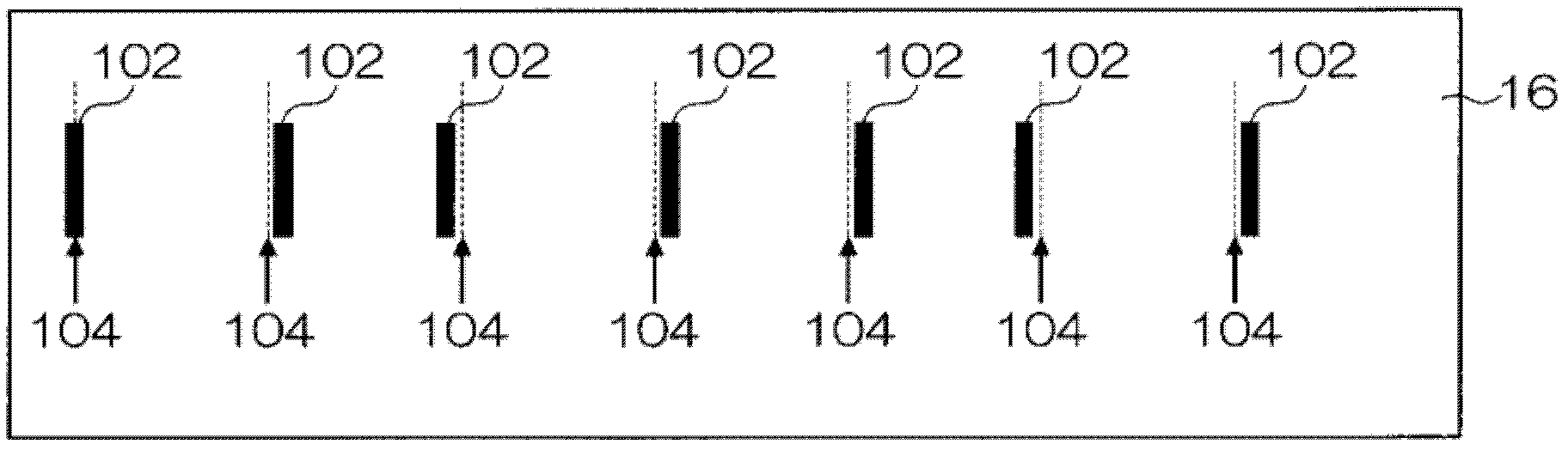

[0083] An error in an ink droplet deposition position (recording position) is introduced as an example of an error caused by a defective nozzle. Figure 1A to Figure 1C is a schematic diagram schematically illustrating a state where the deposition position of the ink droplet ejected from the nozzle deviates from the ideal deposition position on the recording medium. Figure 1A It is a plan view showing a line arrangement of a plurality of nozzles 51 in the head 50 . Figure 1B is a schematic diagram of a state in which ink droplets are ejected from nozzles 51 toward a sheet of recording medium or paper (hereinafter referred to as "recording paper") 16 viewed from the lateral direction. exist Figure 1B , arrow A schematically indicates the ejection direction of ink droplets from nozzles 51 . Figure 1C is a schematic diagram showing an example of a test pattern 102 formed on the recording paper 16 by ink droplets ejected from the nozzle 51 and deposited on the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com