Filling device capable of filling high-temperature and high-viscosity materials

A filling device and high-viscosity technology, which is applied in the field of filling devices capable of filling high-temperature and high-viscosity materials, can solve the problems of unsmooth filling, inaccurate filling volume, and material retention in the material pipe, so as to improve production efficiency and improve Filling speed, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

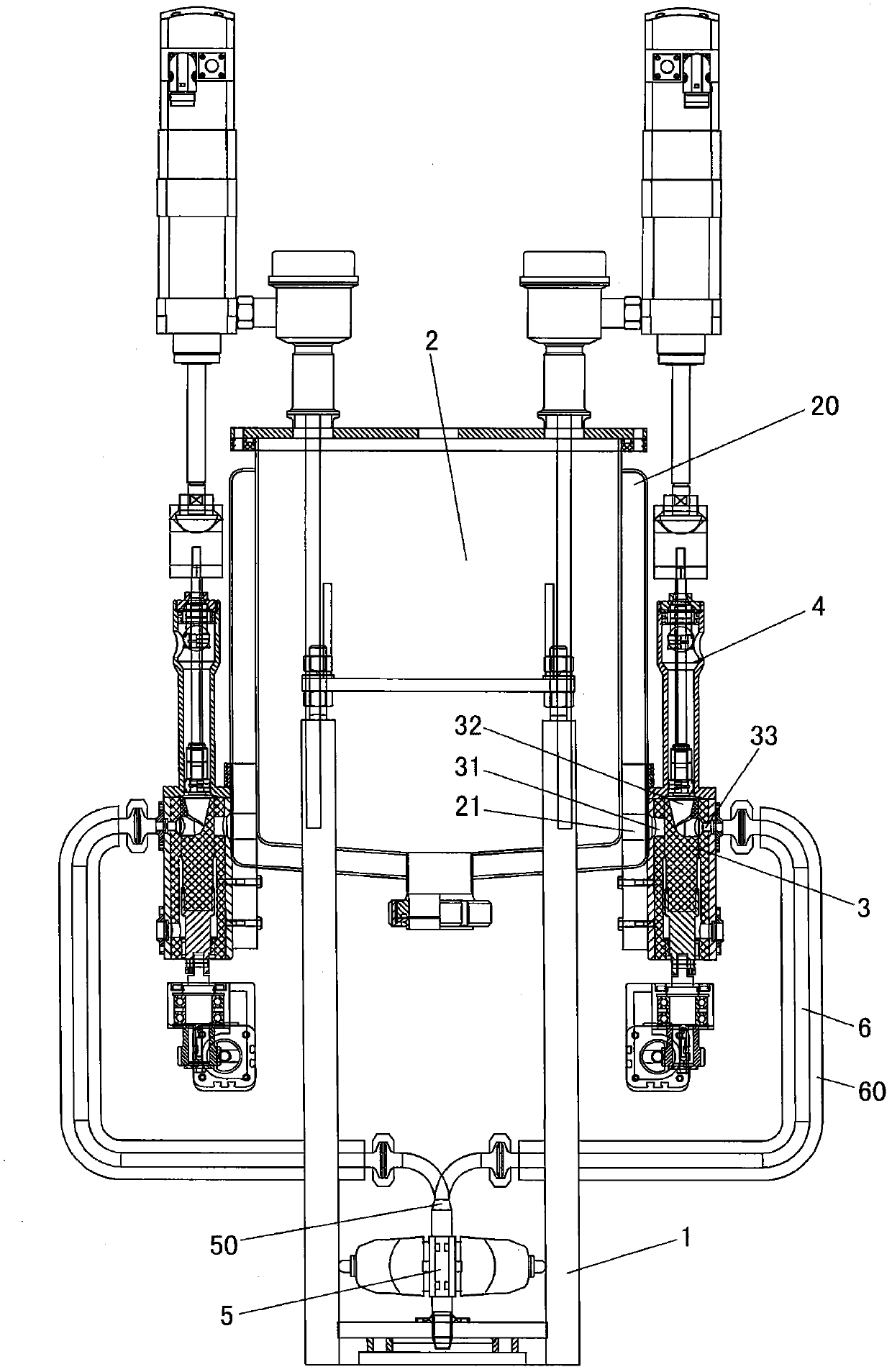

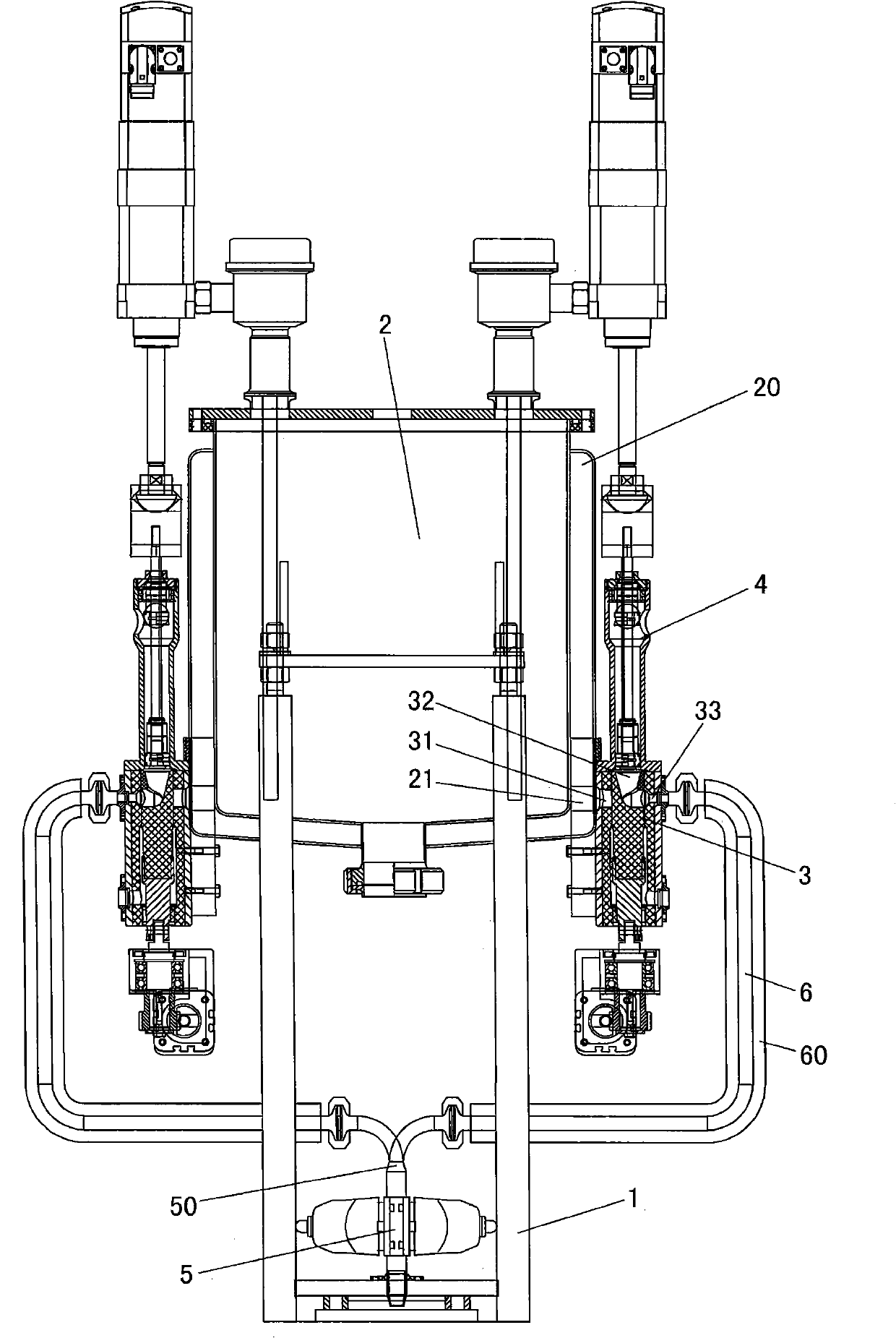

[0017] As shown in the drawings, the filling device in this preferred embodiment that can be filled with high-temperature and high-viscosity materials includes a frame 1, a material barrel 2, a reversing valve 3, a filling pump 4, and a filling head 5. The above-mentioned material barrel 2, filling The pump 4 and the filling head 5 are respectively arranged on the frame 1, the above-mentioned reversing valve 3 is directly arranged on the material barrel 2, and the feed port 31 of the above-mentioned reversing valve 3 is directly connected with the discharge port 21 of the material barrel 2, and the above-mentioned The filling pump 4 is connected to the reversing passage 32 of the reversing valve 3 , and the material outlet 33 of the reversing valve 3 is connected to the feeding port 50 of the filling head 5 through the material pipe 6 .

[0018] The outer surface of the above-mentioned material barrel 2 is provided with a hot water insulation layer 20, through the hot water ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com