Packaging belt embossed tension adjusting device and packaging belt production line

A tension adjustment device and technology of packing belts, which are applied in the directions of transportation and packaging, winding strips, sending objects, etc., can solve the problems of uneven thickness, poor skewness, and different widths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

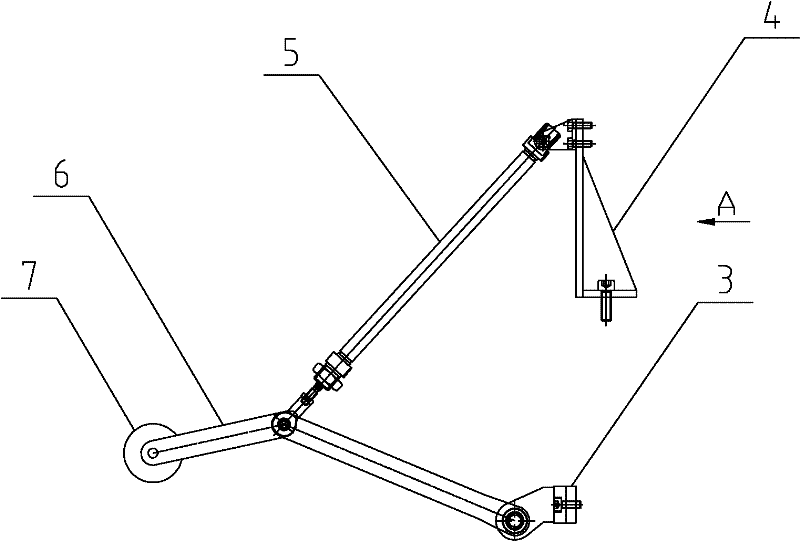

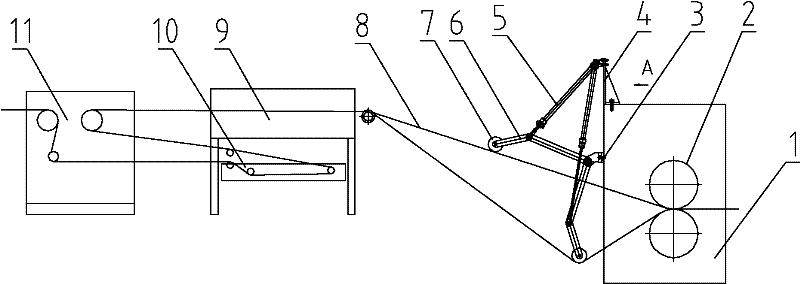

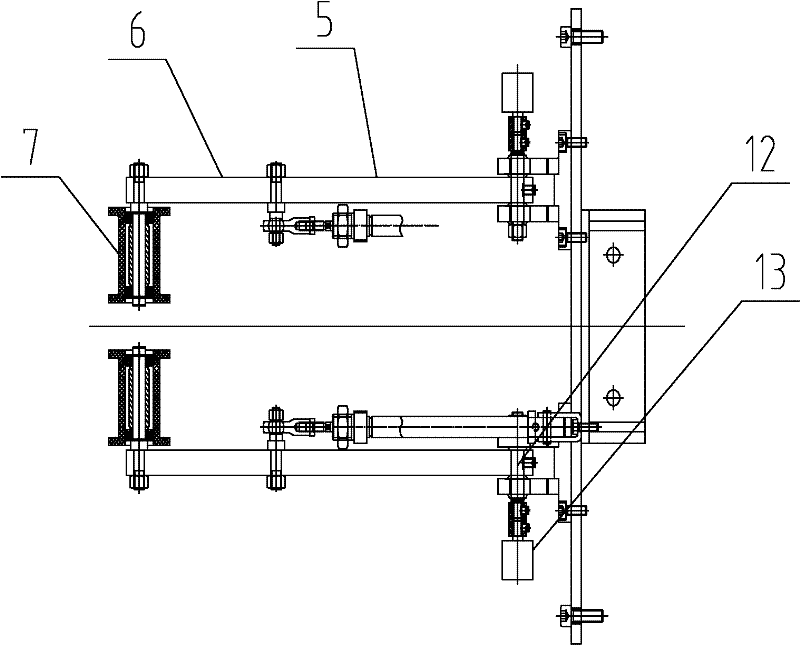

[0020] The basic idea of the preferred embodiment of the present invention is to ensure that the tension balance of the packing belt between the embossing machine and the third pulling machine after embossing is ensured. It is based on the following reasons: the strap enters the embossing machine for embossing after being stretched and deformed. Since the plastic is heated, stretched and deformed, internal stress will be generated in the strap, so it is necessary to eliminate the internal stress of the strap through a shaping oven and a shaping cooling water tank. , the tension of the belt is very critical when the stress is relieved. If the internal stress of the belt can be eliminated evenly while ensuring the balanced tension, the deformation of the belt during winding can be very small, so that a high-quality packing belt can be finally obtained.

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap