Intelligent compensation device for elongation quantity of cage carrying rope and intelligent compensation method thereof

A compensation device and compensation method technology, used in transportation and packaging, lifting equipment in mines, elevators, etc., can solve problems such as high requirements for stopping the tank, lifting wire ropes, affecting the life of wire ropes, etc., to achieve good economic benefits and social benefits. effect, stable entry and exit of the cage, and good practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings.

[0027] An intelligent compensation device for the elongation of the steel wire rope carried by the cage, including a PLC and a weighing device; weighing devices are installed at the wellhead and underground, and the PLC is used to receive the weight signal output by the weighing device and judge the lifting winch to stop releasing the wire rope. starting point.

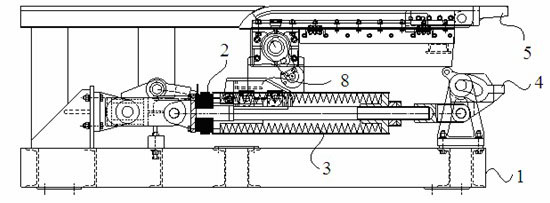

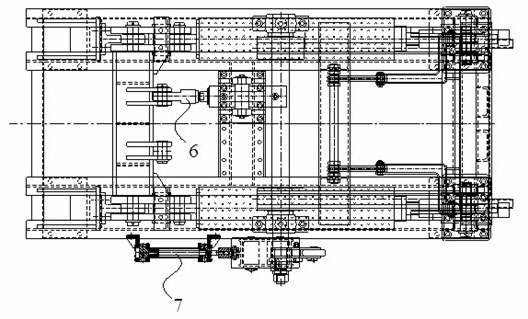

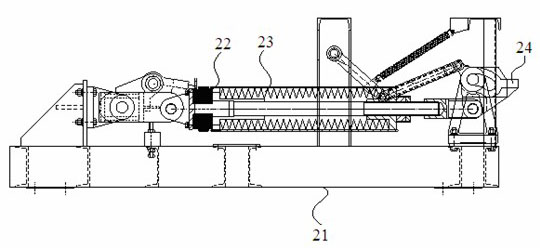

[0028] There are 4 typical weighing devices, 2 at the wellhead and 2 at the bottom. Such as figure 1 and figure 2 As shown, the structures of the two wellhead cage weighing support tanks are exactly the same, and the main components are composed of frame 1, weighing device 2, buffer 3, supporting claw 4, rocker arm 5, trolley 8, claw cylinder 6 and trolley cylinder 7 . Frame 1 is a square frame, fixed by bolts. The weighing device 2 can be an ordinary load cell, preferably an axle load type load cell. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com