Hoisting rack for hoisting and mounting condenser shell module

A hoisting frame and condenser technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as poor economy, influence of condenser shell modules, and inability to lift the condenser over obstacles, etc., to achieve Convenient transportation, convenient on-site disassembly and assembly, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

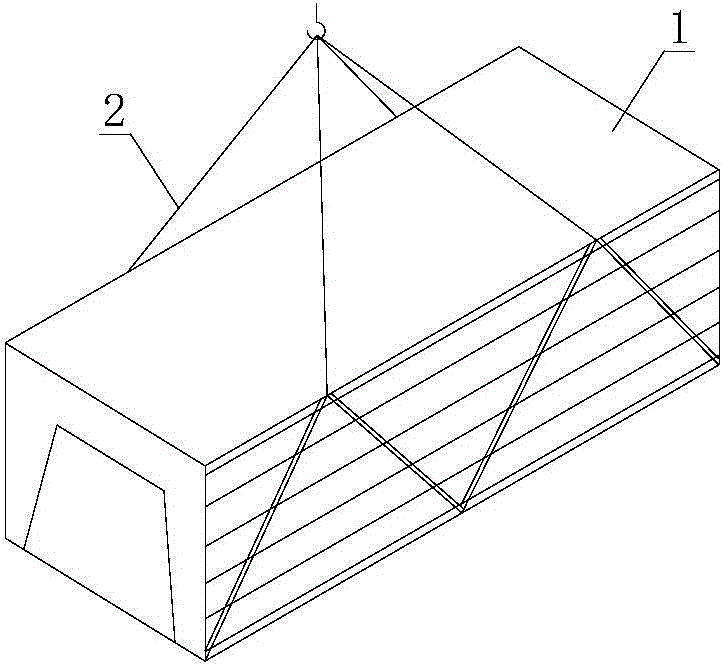

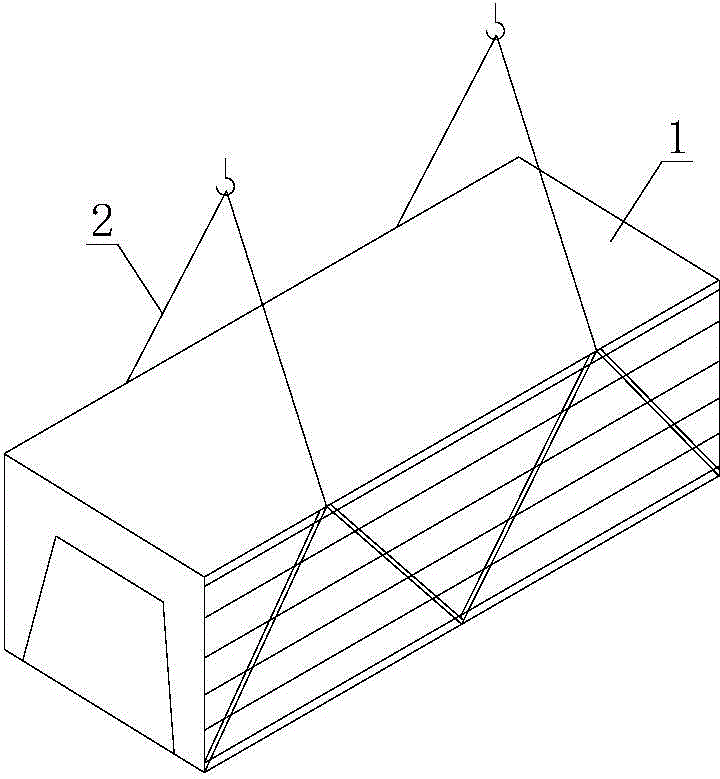

[0026] The hoisting frame for hoisting and installing the condenser shell module of the present invention will be further described in detail below in conjunction with the accompanying drawings.

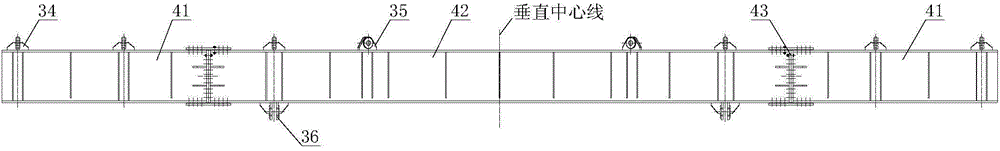

[0027] Such as Figure 2a , 2b , 2c, the hoisting frame used to install the condenser shell module in this example includes a main beam 31, a transverse strut 32, an oblique strut 33, a top transverse lug 34, and a top oblique lug 35 And bottom surface lug 36. Each part of the hoisting frame is welded by section steel or steel plate. The structure is simple and compact, and it is easy to process and manufacture. The components are connected by flanges, which is convenient for installation and removal. There are two main beams, and the two main beams are connected by transverse struts and oblique struts to jointly form the main frame of the hoisting frame for load bearing. The two main beams are symmetrically arranged on the longitudinal centerline of the main frame. On both sides;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com