Contact lens material, contact lenses, and manufacturing method for contact lenses

A technology of contact lenses and manufacturing methods, applied in glasses/goggles, instruments, optics, etc., can solve the problems of glasses inflammation, bacterial growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In one embodiment of the present invention, the present invention provides a contact lens material, and the contact lens material has a hydrophilic surface and can form a contact lens with high oxygen permeability and high water content.

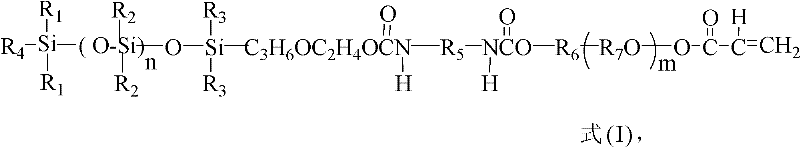

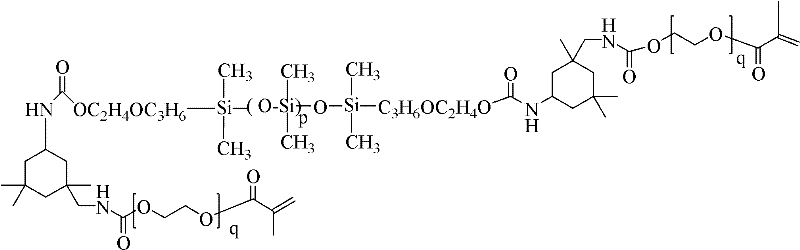

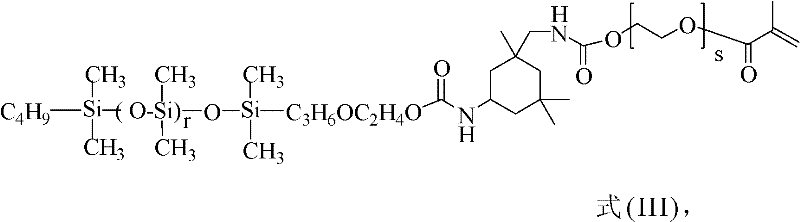

[0049] The contact lens material provided by the present invention may comprise a siloxane polymer represented by formula (I), at least one hydrophilic monomer, a crosslinking agent or a siloxane polymer represented by formula (II) and Initiator, but not limited thereto, wherein the molecular weight of the siloxane polymer represented by formula (I) is about 1000 to 10000, and formula (I) and formula (II) are respectively as follows:

[0050]

[0051] In formula (I), R 1 , R 2 with R 3 for C 1 -C 4 Alkyl, R 4 for C 1 -C 6 Alkyl, R 5 Residues obtained by removal of NCO groups from aliphatic or aromatic diisocyanates, R 6 with R 7 is an alkylene group, and n is an integer of about 4-80, m is an integer of about 3-40, and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com