Chemical-mechanical polishing liquid

A chemical-mechanical, polishing liquid technology, used in polishing compositions containing abrasives, electrical components, semiconductor/solid-state device manufacturing, etc., to achieve the effect of small scratches and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

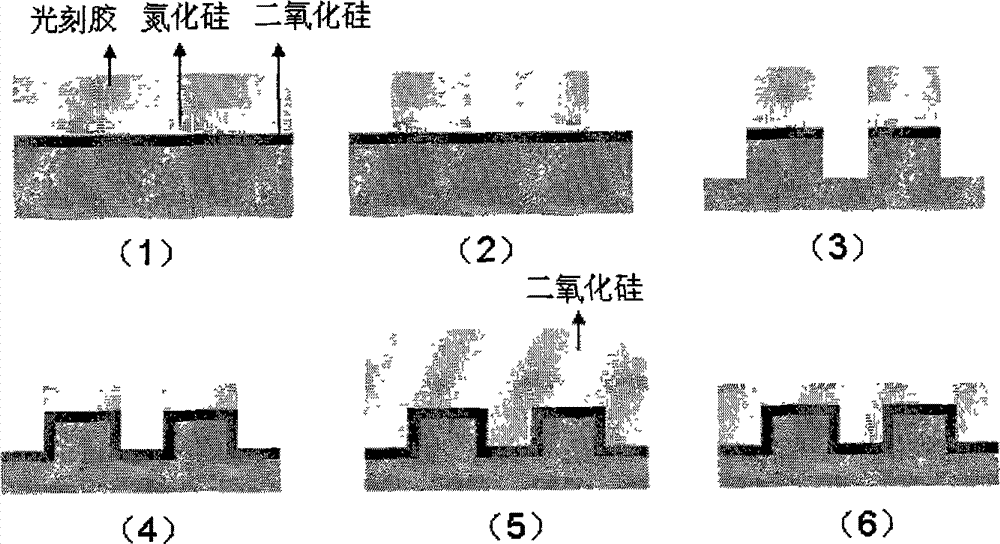

Image

Examples

Embodiment Construction

[0009] The present invention will be further explained by the method of examples below, and the present invention is not limited to the scope of the described examples.

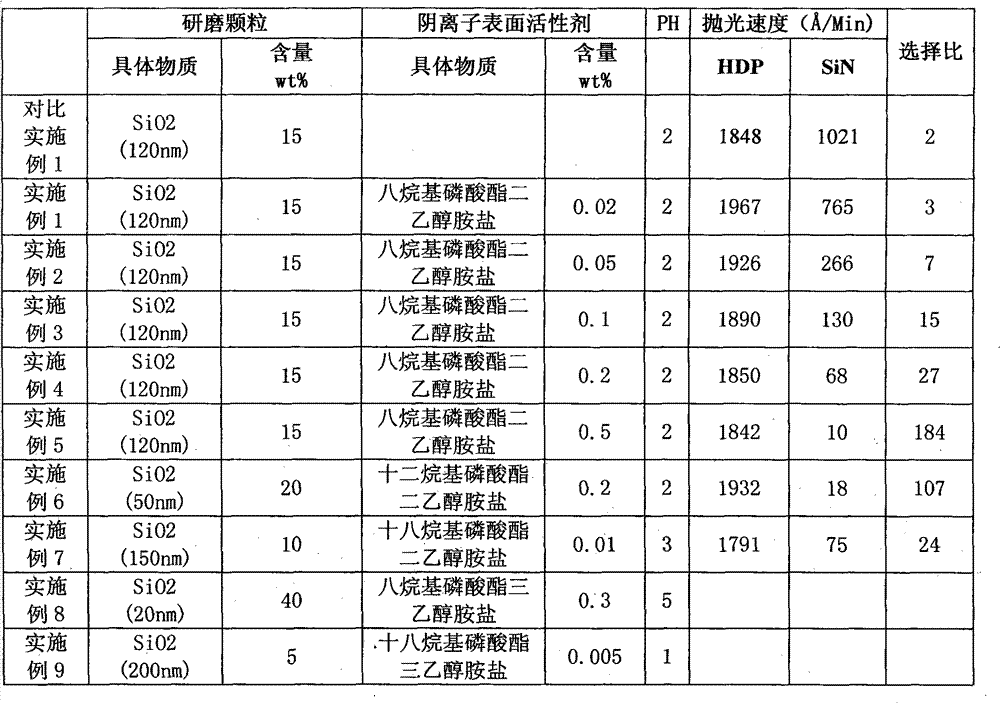

[0010] Table 1 shows the formulas of Examples 1-9 of the chemical mechanical polishing liquid of the present invention and the comparative examples. According to the formula in the table, the ingredients are simply and uniformly mixed, the balance is water, and then potassium hydroxide, ammonia and nitric acid are used. Adjusting to a proper pH value, the polishing liquid of each embodiment can be prepared.

[0011] Table 1 Chemical mechanical polishing liquid examples 1-9 and comparative examples of the present invention

[0012]

[0013] Using the polishing liquid of Comparative Example 1 and Examples 1-7 of the present invention, the blank HDP-Oxide wafer and the blank Si 3 N 4 The wafer is polished. Polishing conditions: the polishing pad is PPG 14', the down pressure is 4psi, the rotating speed is polishing di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com