Feedforward control method of furnace top pressure of blast furnace

A feedforward control, blast furnace technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problem of low precision of large-lag control objects, and achieve the effect of overcoming slow response speed, forward running and increasing output, and improving control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

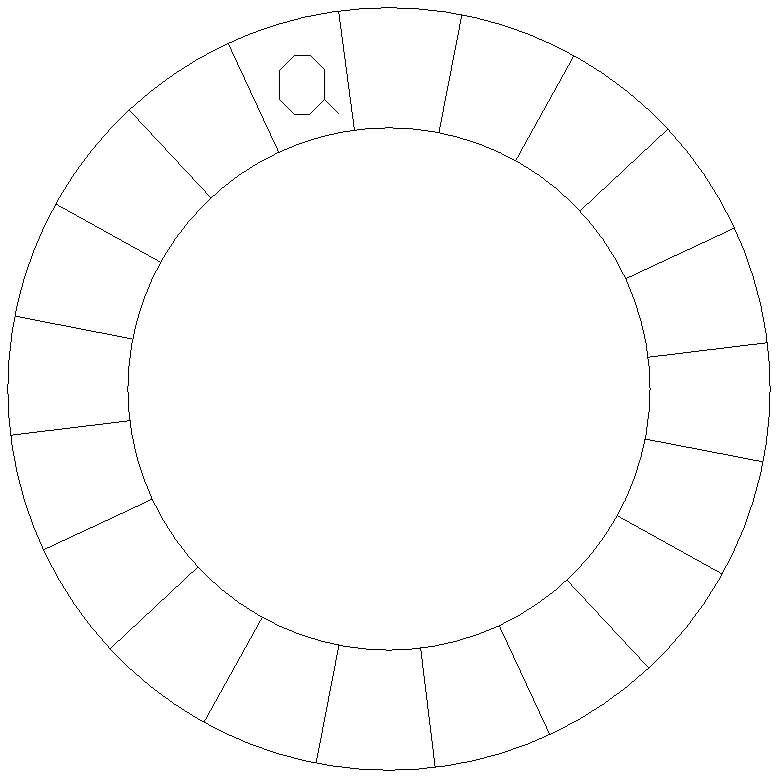

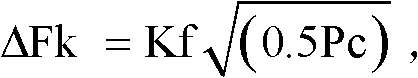

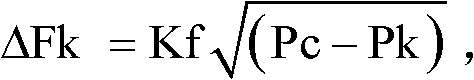

[0020] The feed-forward control method for blast furnace roof pressure provided by the present invention is specifically as follows: by analyzing the technological process of the blast furnace, it is considered that the pressure equalization of the furnace roof distribution and the distribution tank is the main factor affecting the stability of the furnace roof pressure in the normal production process of the blast furnace. The internal relationship of its relevant parameters is used to establish the top pressure feed-forward control mathematical model of the furnace top distribution and pressure equalization process, and the corresponding stator vane angle control value in the process is calculated as the feed-forward amount, using the PID+feed-forward mathematical model method to control the top pressure; the top pressure feedforward control can act on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com