Sacrificial anode assembly

A sacrificial anode and component technology, which is applied in the field of marine engineering, can solve problems such as low current efficiency, negative open circuit potential, and small anode capacitance, and achieve the effects of low manufacturing cost, convenient installation, and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

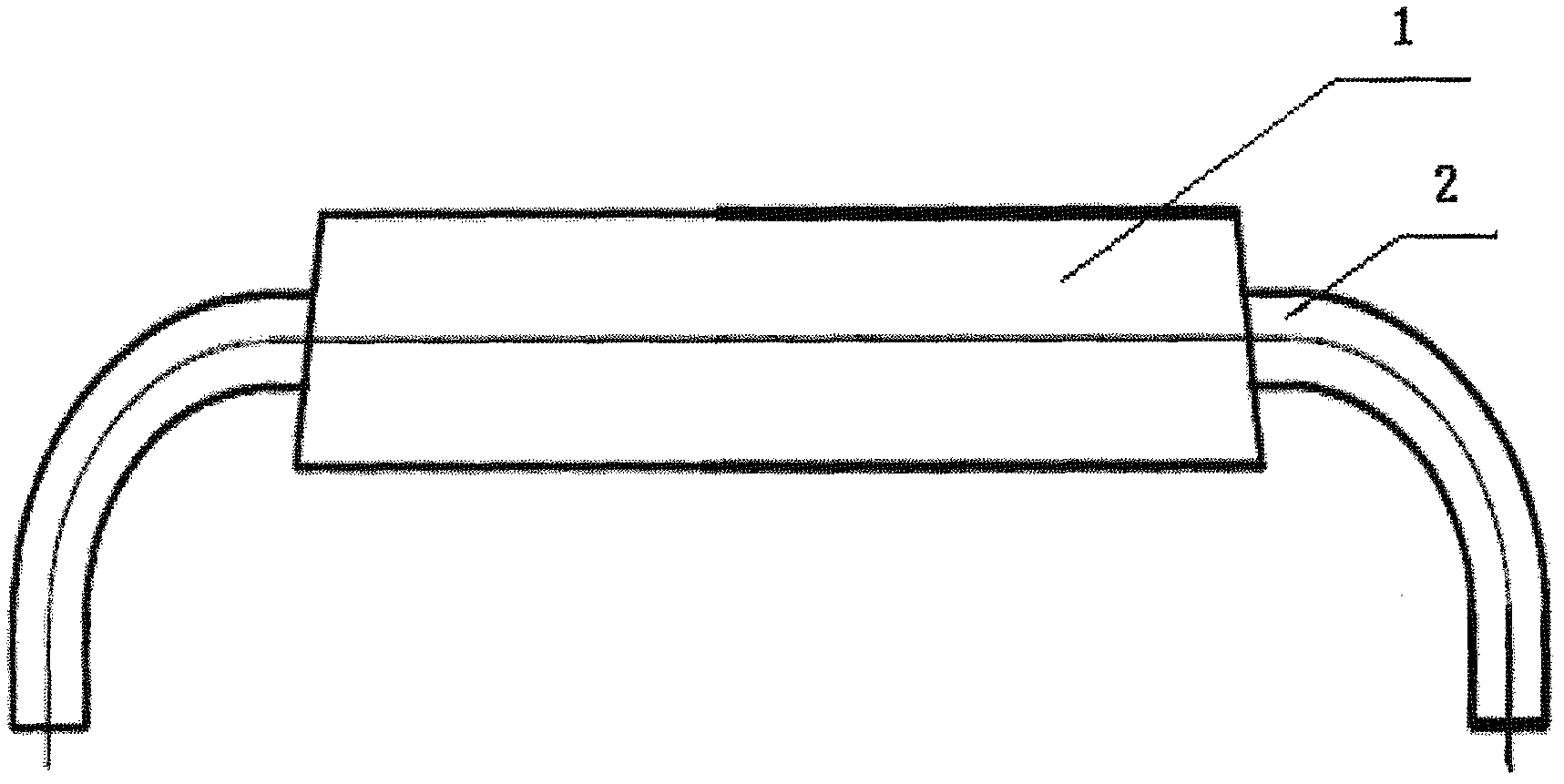

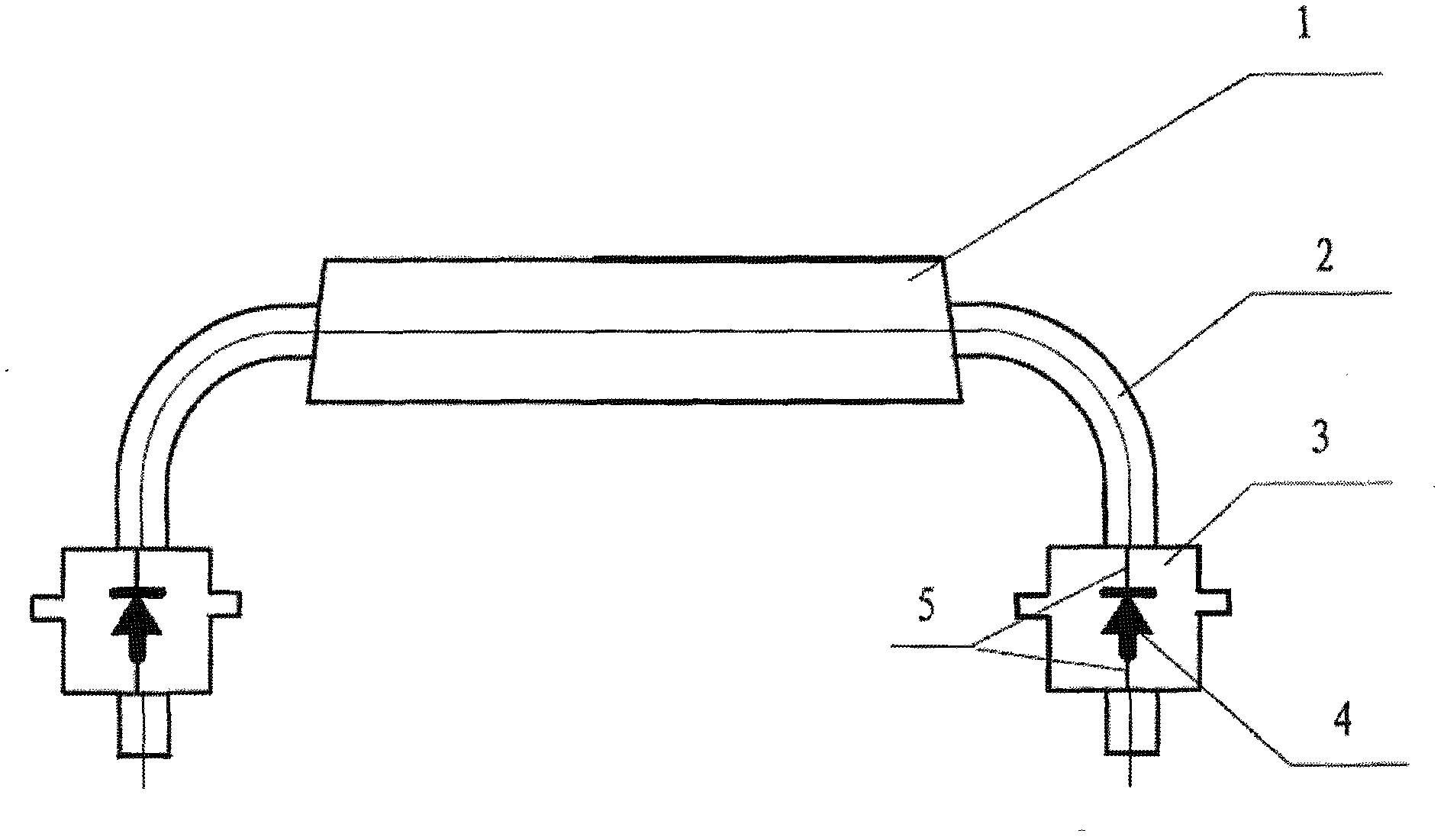

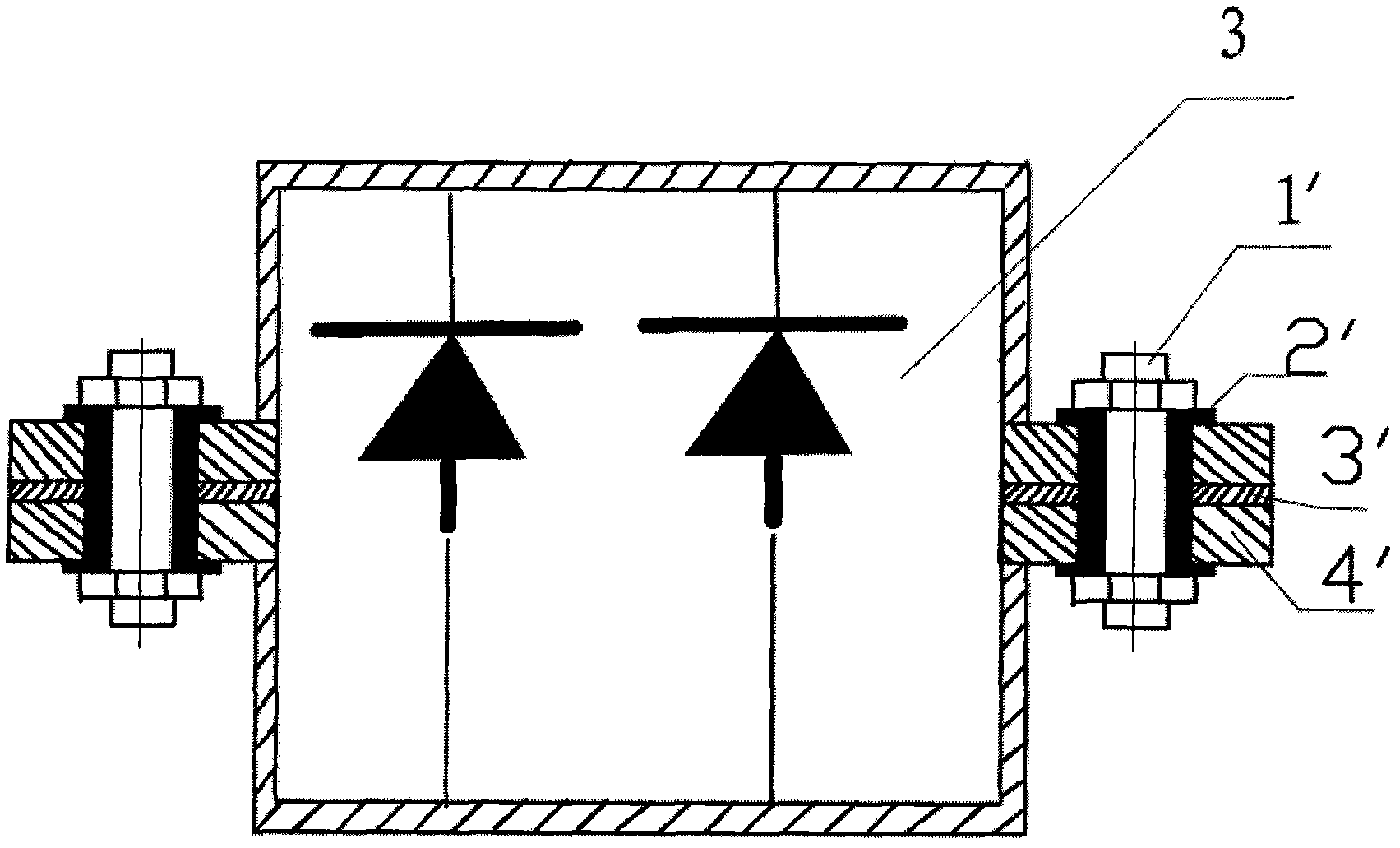

[0021] Such as Figure 2-Figure 4 As shown, the present invention includes: an anode body 1 , an anode leg 2 , a diode 4 and a steel protection box 3 . The anode body 1 is sleeved on the outside of the anode leg 2, and the material of the anode body 1 is aluminum, zinc, magnesium, aluminum-zinc composite material, zinc-magnesium composite material, aluminum-magnesium composite material or aluminum-zinc-magnesium composite material. The diode 4 is connected in series to the anode leg 2 through the wire 5, and the diode 4 is placed in the steel protection box 3; wherein, each anode leg 2 is connected in series with a diode 4, and the number of the diode 4 connected in series can be 1 or more, and the multiple diodes 4 connected in series are connected in parallel. The purpose of connecting multiple diodes in series is to disperse the large current, so that the current passing through each diode 4 becomes smaller, so as to prevent a certain The diode 4 is damaged so that the who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com