Electroplating hanging tool and manufacturing method thereof

An electroplating hanger and electroplating layer technology, applied in the electrolytic process, electrolytic components and other directions, can solve the problems of uneven thickness of the electroplating layer, affecting product performance, etc., to achieve uniform thickness of the electroplating layer, improve product performance, and overcome the effect of edge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

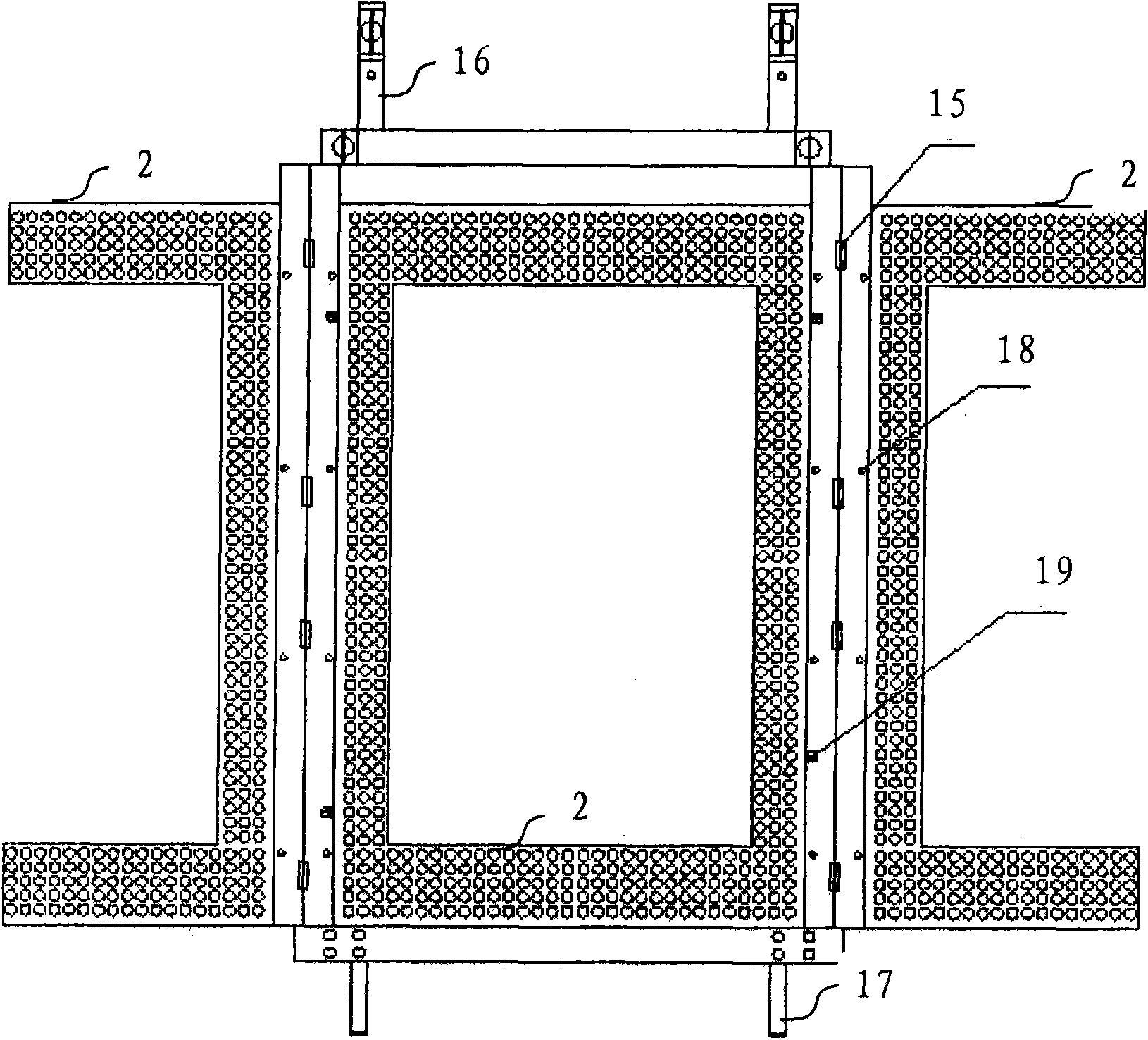

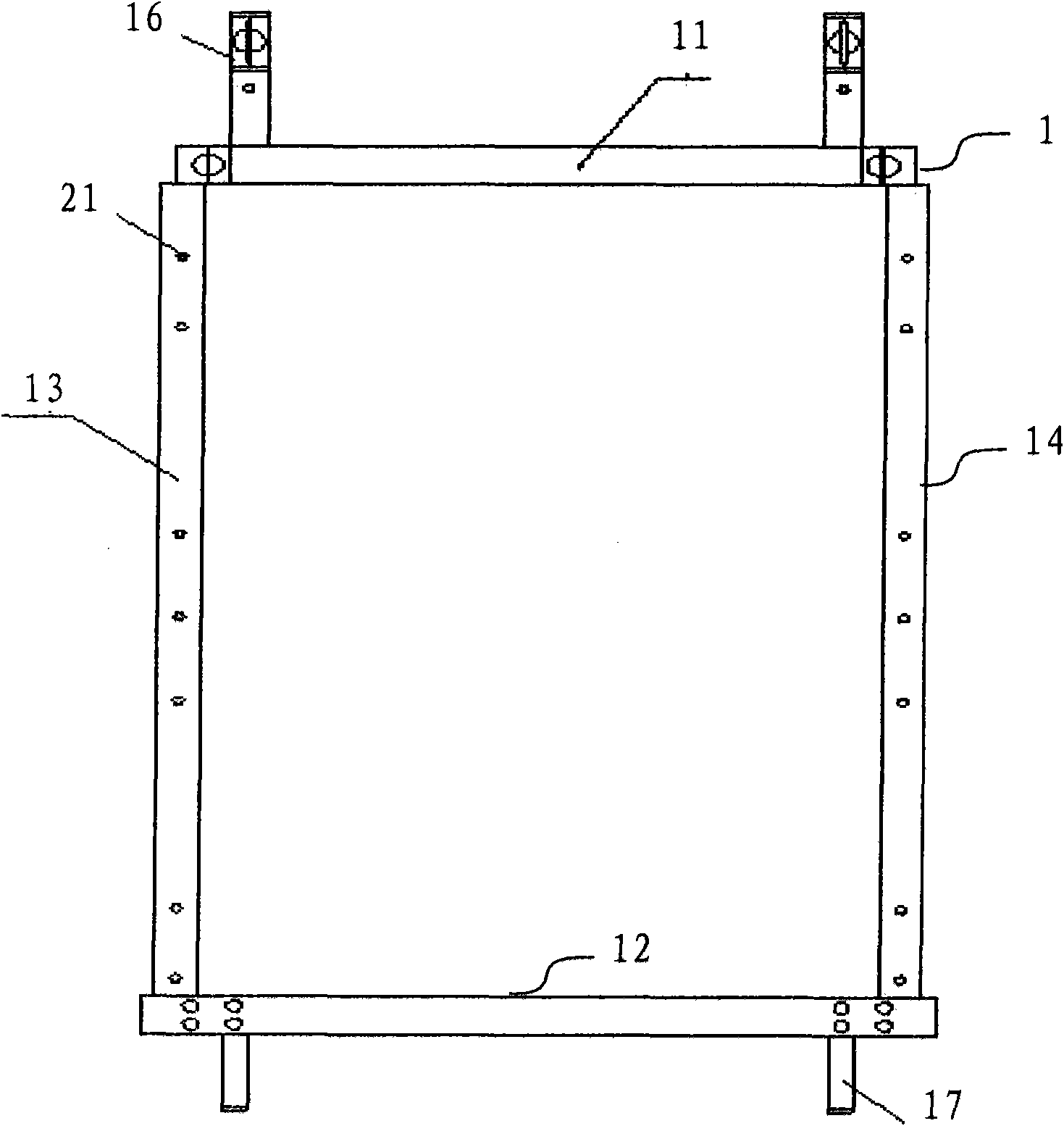

[0032] A kind of preparation method of electroplating hanger of the present invention is characterized in that, comprises:

[0033] Install the circuit board on the hanger;

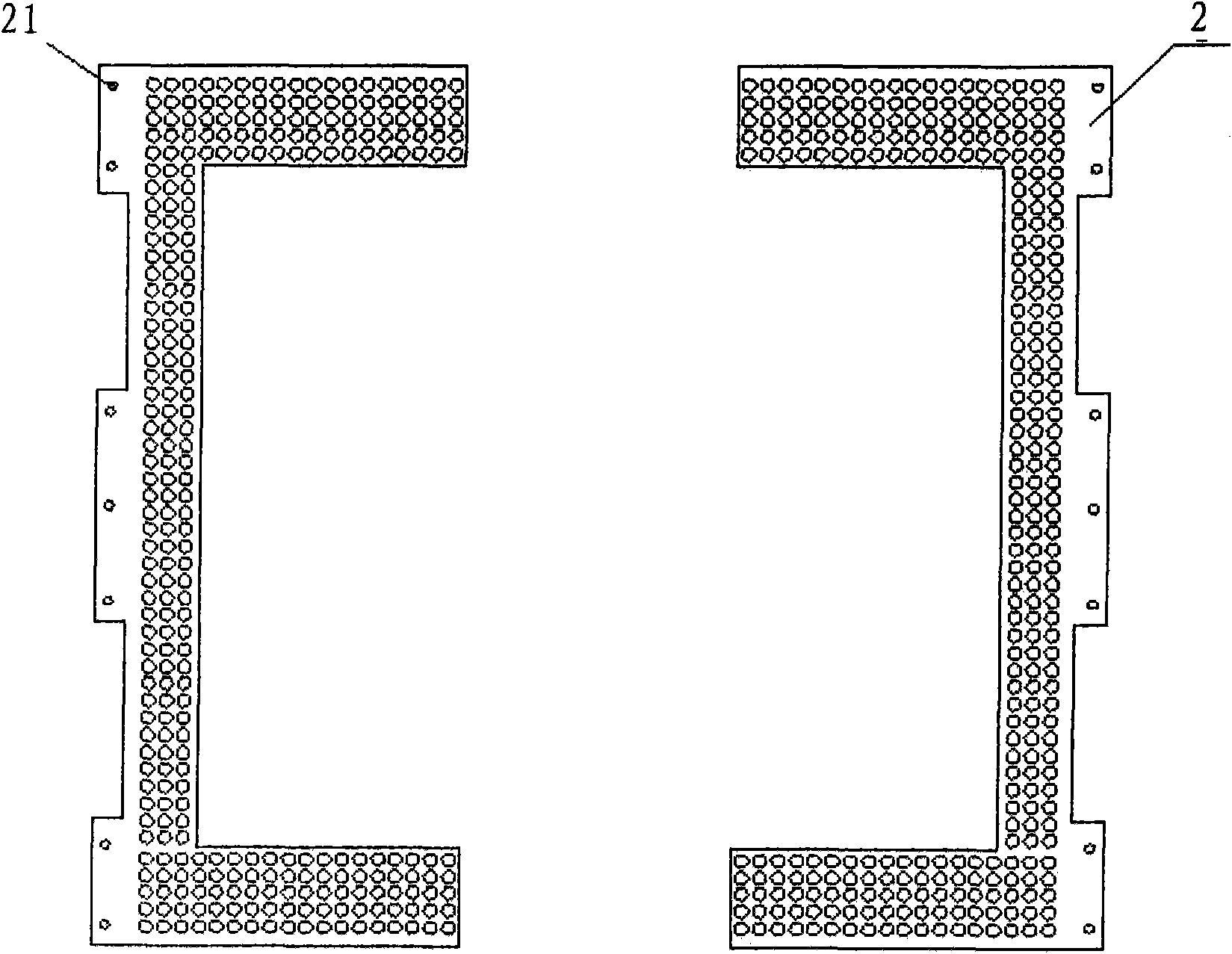

[0034] Making a shielding plate, wherein, the shielding plate is provided with a plurality of through holes, and the shielding plate is made of non-conductive material;

[0035] The shielding plate is installed on the hanger, so that: when the circuit board is installed on the hanger, the shielding plate shields the edge part or the whole plating area of the electroplating area of the circuit board.

[0036] Preferably, in each embodiment of the present invention, after the step of installing the circuit board on the hanger and before the step of making the shielding board, further include:

[0037] Carry out electroplating to the circuit board that is installed on the hanger;

[0038] Measure the thickness of the electroplating layer on each part of the surface of the electroplated circuit board, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com