High-pressure self-sealing cup assembly for reseatable packers

A technology of packer and leather cup, which is applied in the directions of sealing/isolation, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of unsealed operation, shoulder shear damage, and downhole high-pressure operation, etc. To achieve the effect of damage control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

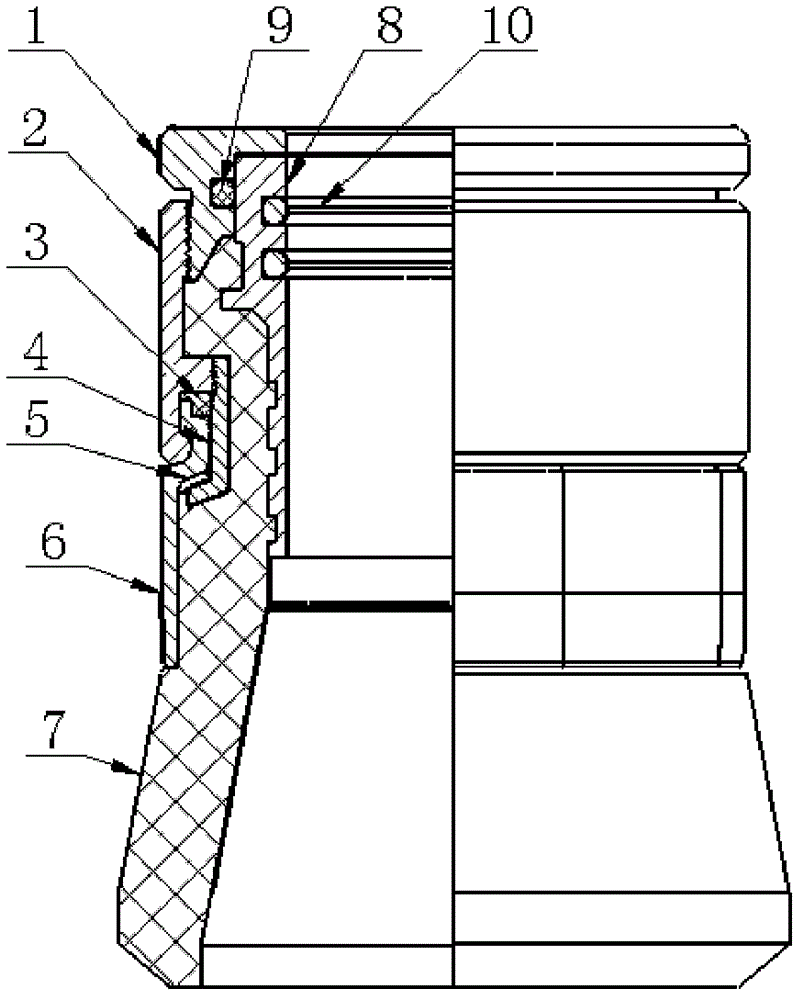

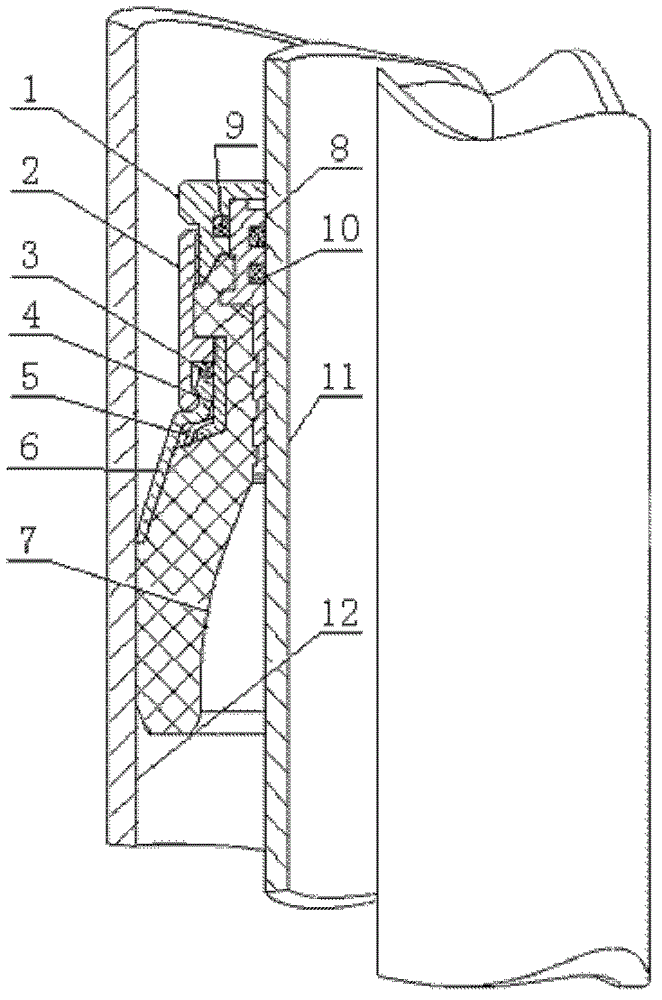

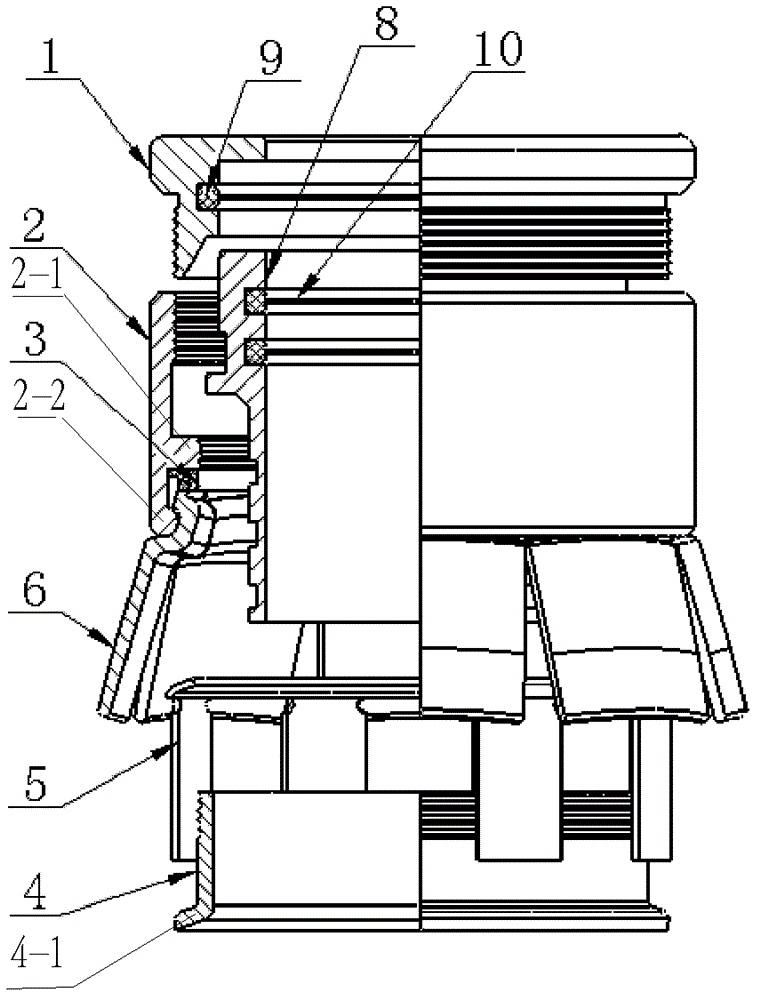

[0017] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a high-pressure self-sealing cup assembly that can be repeatedly seated for a packer includes a rubber cup 7 sleeved on a sealing slip ring 8, and a cup pressure cap 1 is connected to the top of the rubber cup. The shoulder circumference of the rubber cup is provided with several cup shoulder guards 6, and the cup shoulder guard is close to the rubber cup, which can be glued and can also be fixed by a wire rope at the periphery. The leather bowl shoulder guard 6 is a multi-block combined structure, and the leather bowl shoulder guard can be injection molded into one with the rubber leather cup 7. When the plate is launched with the rubber cup, the lower end of the cup shoulder guard can coincide with the inner wall of the sleeve pipe 12, and the cup shoulder guard bears the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com