Servo direct-driven oil pumping unit

A kind of pumping unit, direct-drive technology, applied in the direction of electromechanical device, control of mechanical energy, extraction of fluid, etc., can solve the problems of restricting the popularization and application of beamless pumping unit, high power consumption of motor, difficult maintenance, etc. Significant energy-saving effect, improved transmission efficiency, convenient adjustment of counterweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

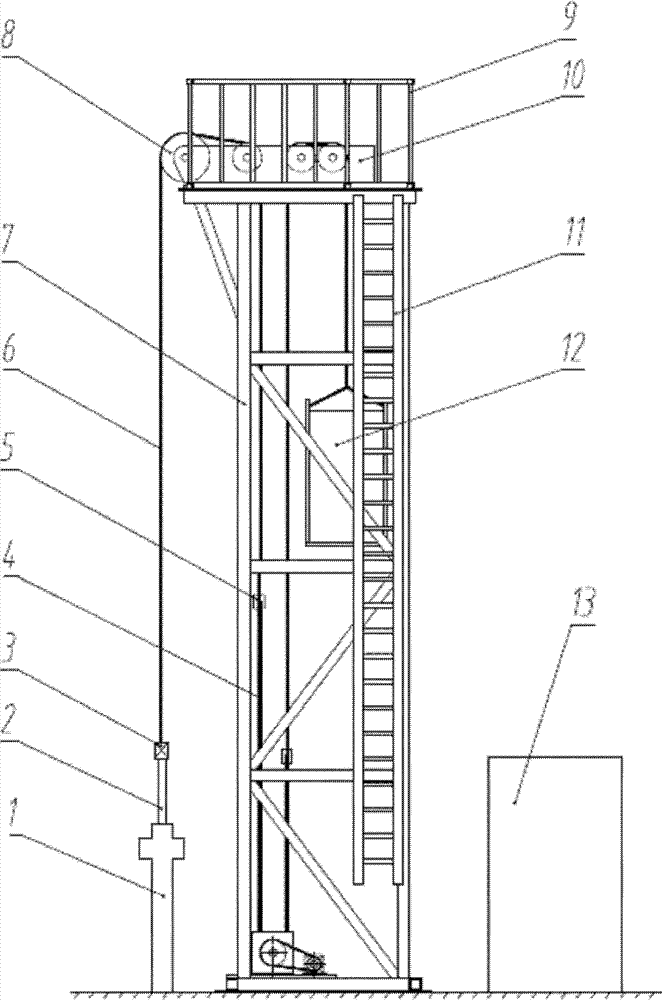

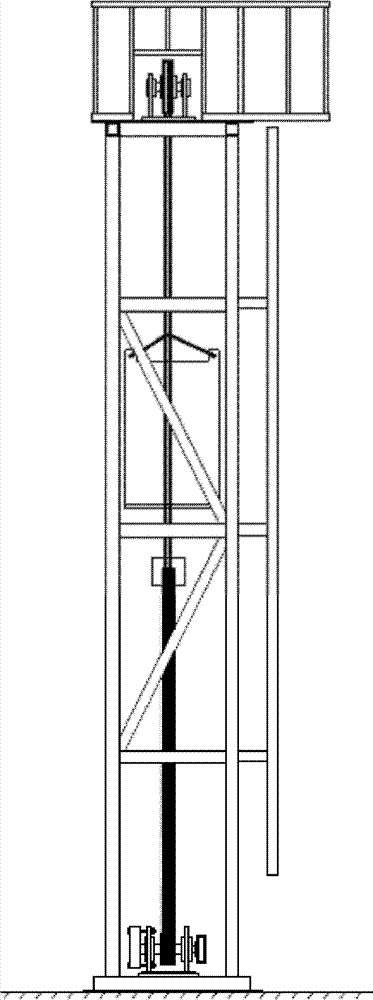

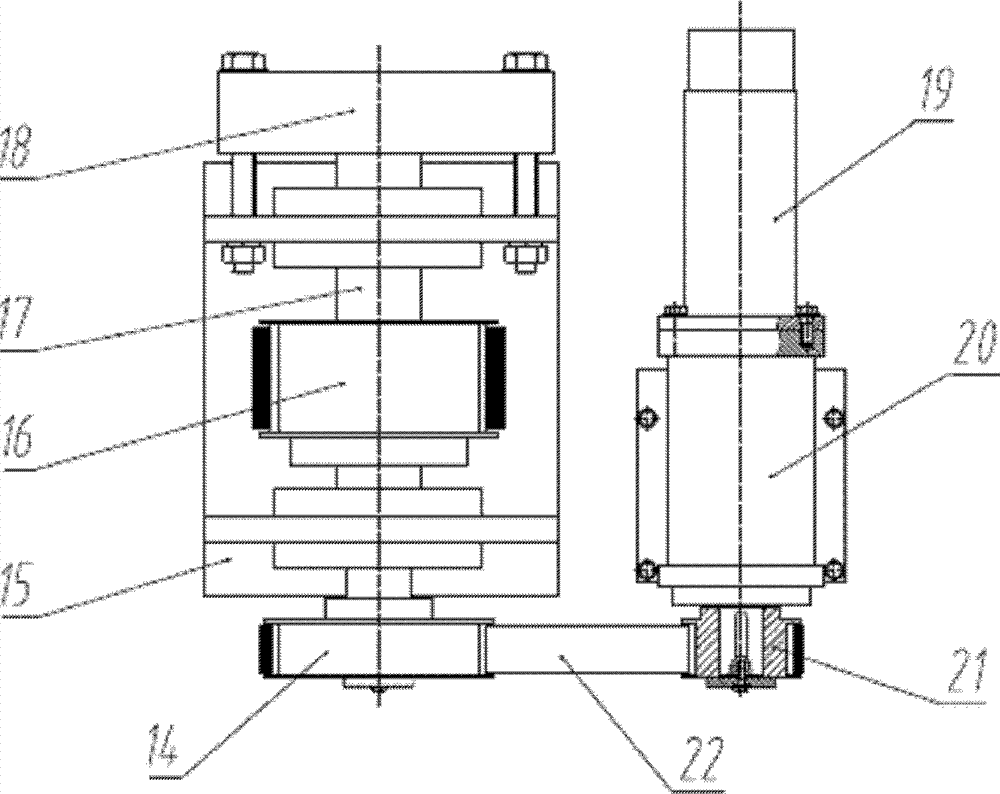

[0027] refer to figure 1 and figure 2 , a servo direct-drive pumping unit, comprising a frame 7, a servo motor 19, a reducer 20, a small transmission synchronous pulley 21, a large transmission synchronous pulley 14, a synchronous toothed belt 22, a brake 18, and a main synchronous belt Wheel 16, drive shaft 17, drive wheel seat 15, guide pulley 8, pulley seat 10, open timing belt 4, steel wire rope 6, counterweight box 12, electric control cabinet 13, guardrail 9, climbing ladder 11 etc. Described frame 7 is integral welding frame, and it is welded by section steel and steel plate, and structure is simple, firm and reliable. The reducer 20 is a two-stage planetary gear reducer. The brake 18 is an electromagnetic friction brake, and brakes when there is no power. The guardrail 9 is installed on the top of the frame 7 by bolts. Described climbing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com