Inflator embedded with pressure gage

A technology for pressure gauges and pumps, applied in the field of pumps, can solve the problems of pressure gauge 40 loosening, unfavorable industrial design, and inability to effectively improve the efficiency of manufacturing and assembly, so as to achieve the effect of improving manufacturing and assembly efficiency and improving the quality of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

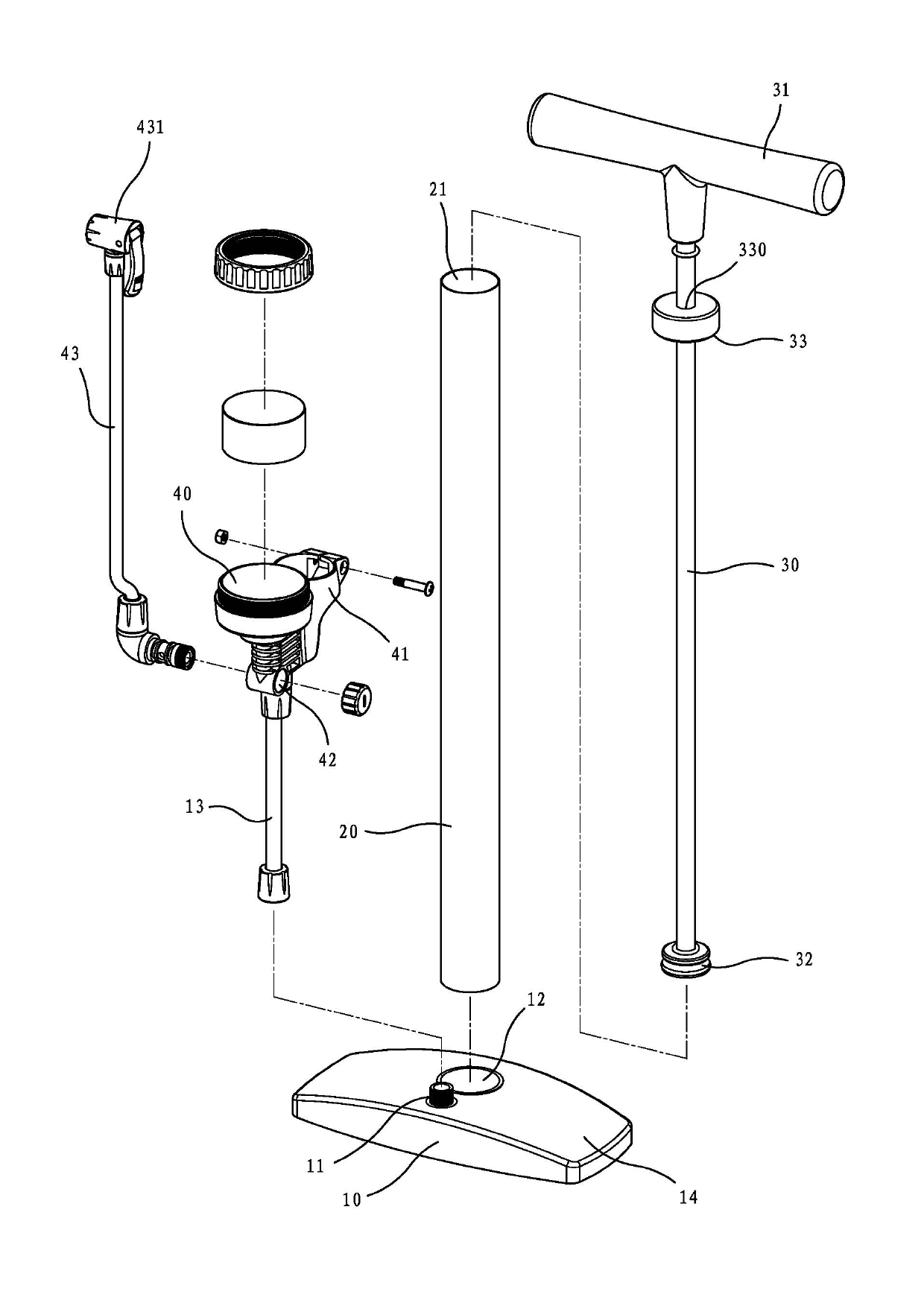

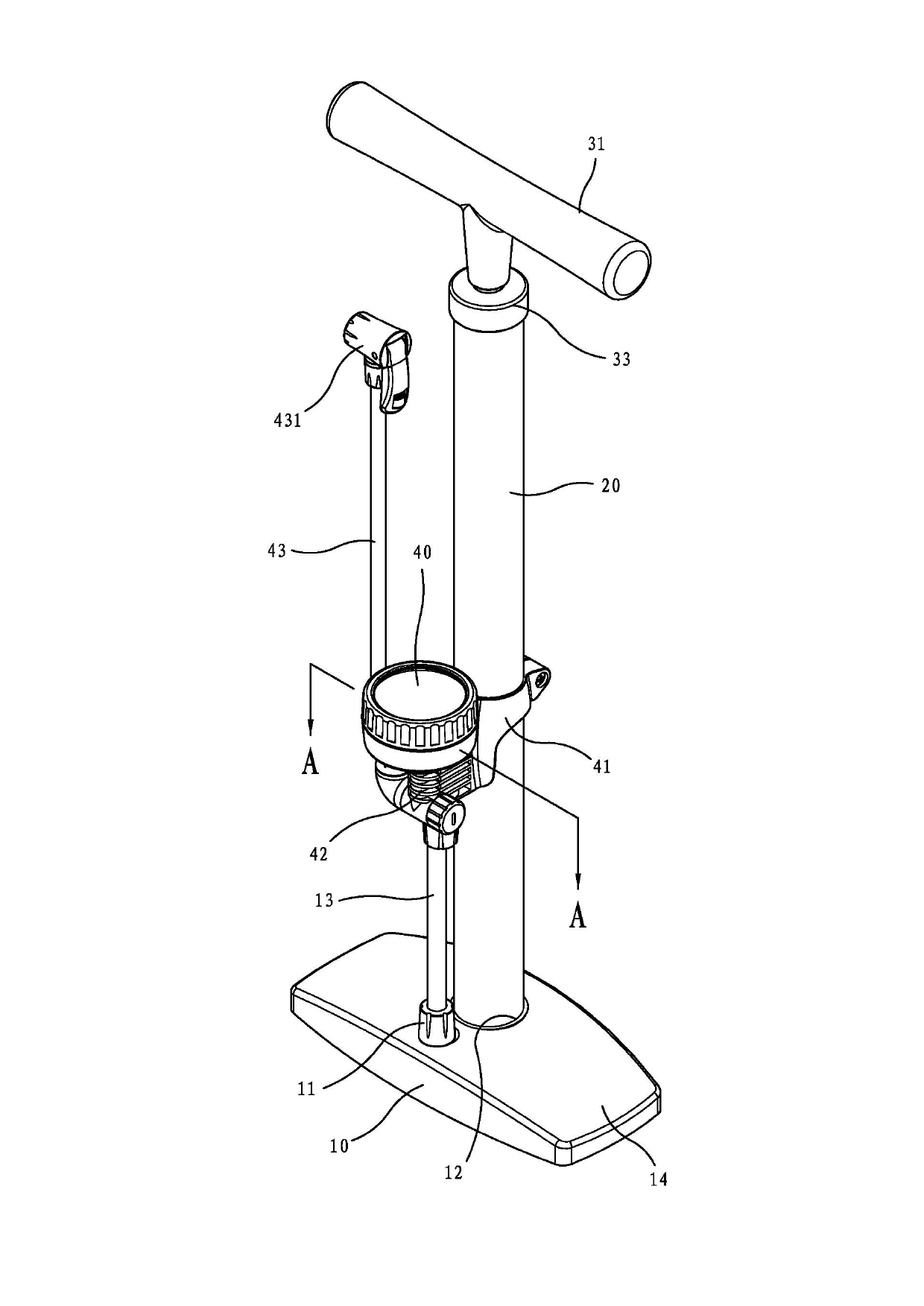

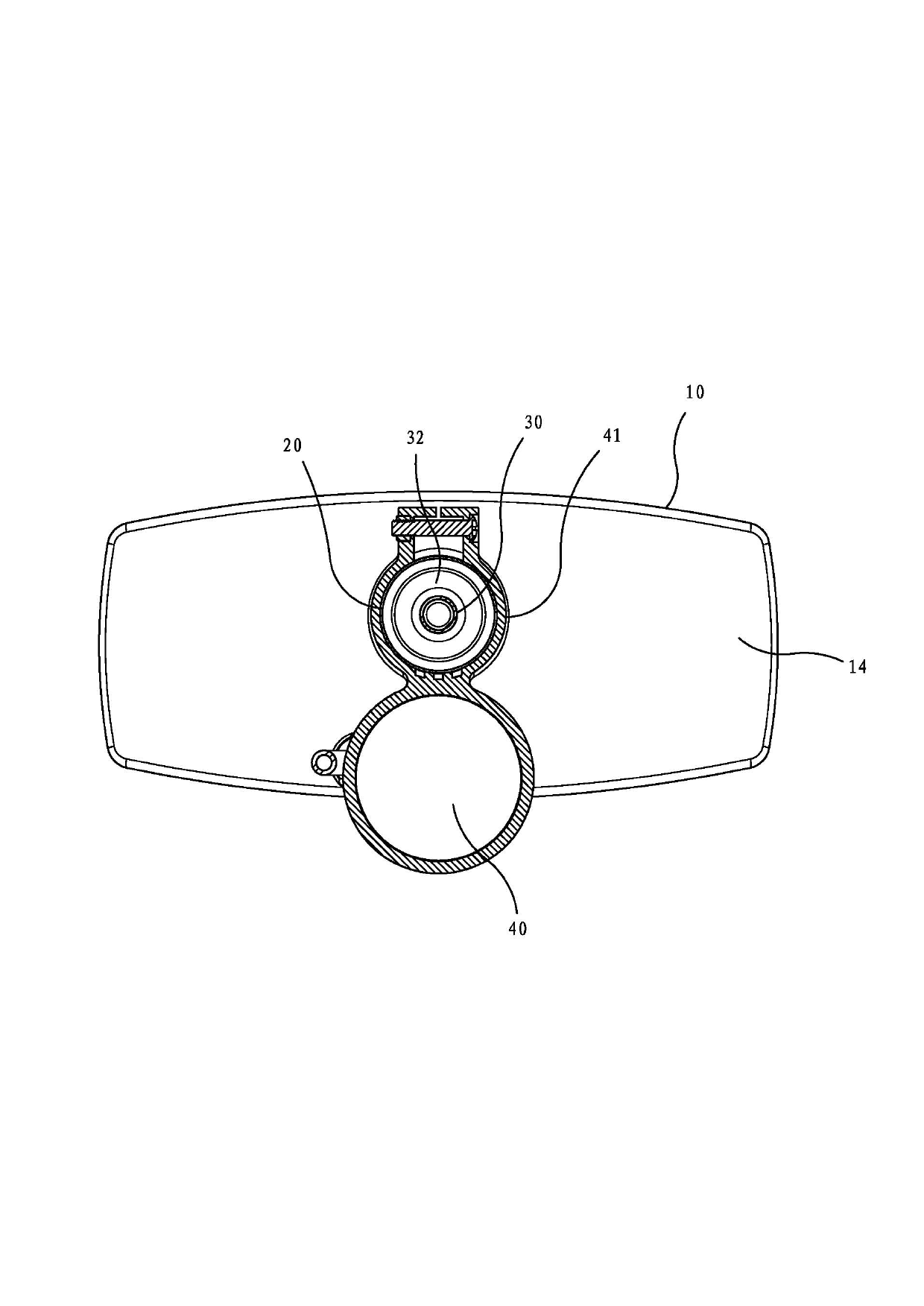

[0076] see Figure 4 to Figure 12 , the present invention includes:

[0077] A base 50, which is provided with a connection hole 511 and an assembly hole 512 with a larger diameter in the central part of the top surface, respectively. 511, the assembly hole 512, and a valve member 53 is installed in the cross passage 52. The valve member 53 has a concentric shaft portion 530 with a smaller diameter in the assembly hole 512. The top surface of the shaft portion 530 is provided with an air delivery hole 531 and a bottom. The end is radially outwardly expanded to form a shoulder 532, and the shoulder 532 is connected with a manifold 533 extending into the cross channel 52, and the manifold 533 is connected with a joint 534 protruding from the connecting hole 511. The joint 534 can provide One end of the air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com