Secondary oil cylinder of wood splitting machine

A two-stage oil cylinder and wood splitter technology, which is applied in the direction of fluid pressure actuation devices, can solve the problems of large shape and installation distance, and achieve the effects of reducing transportation costs, shortening the installation distance of the shape, and improving speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

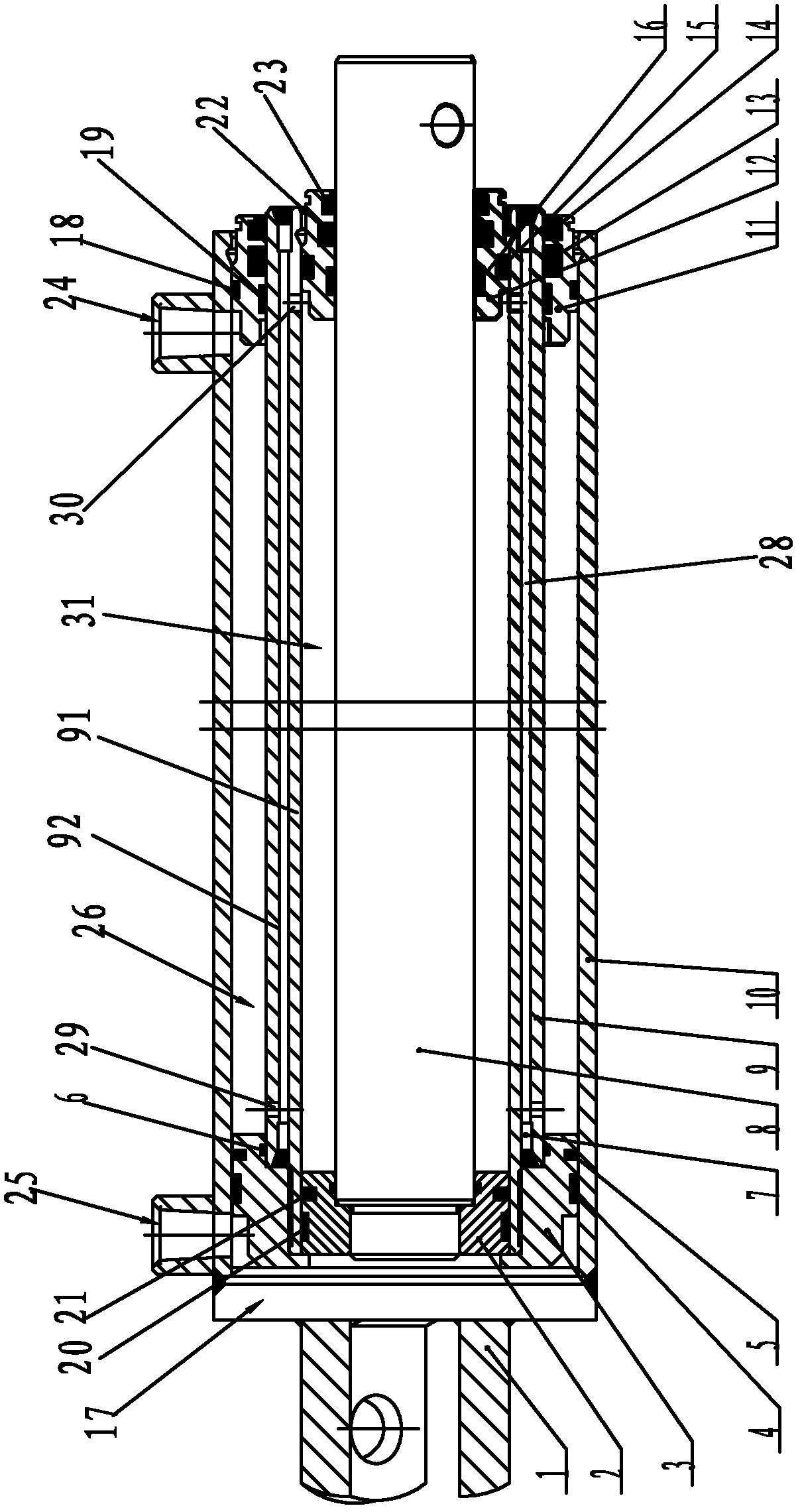

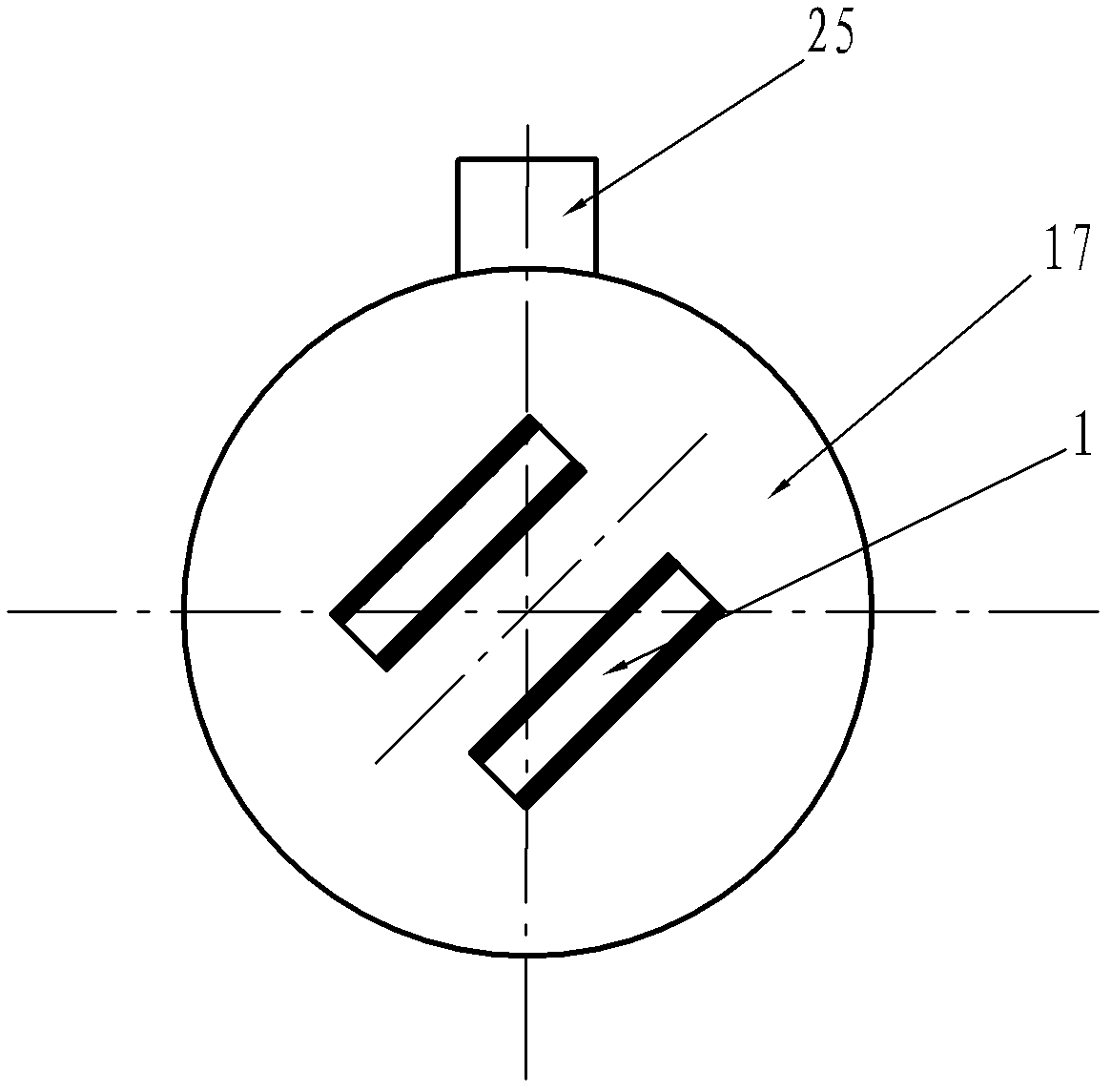

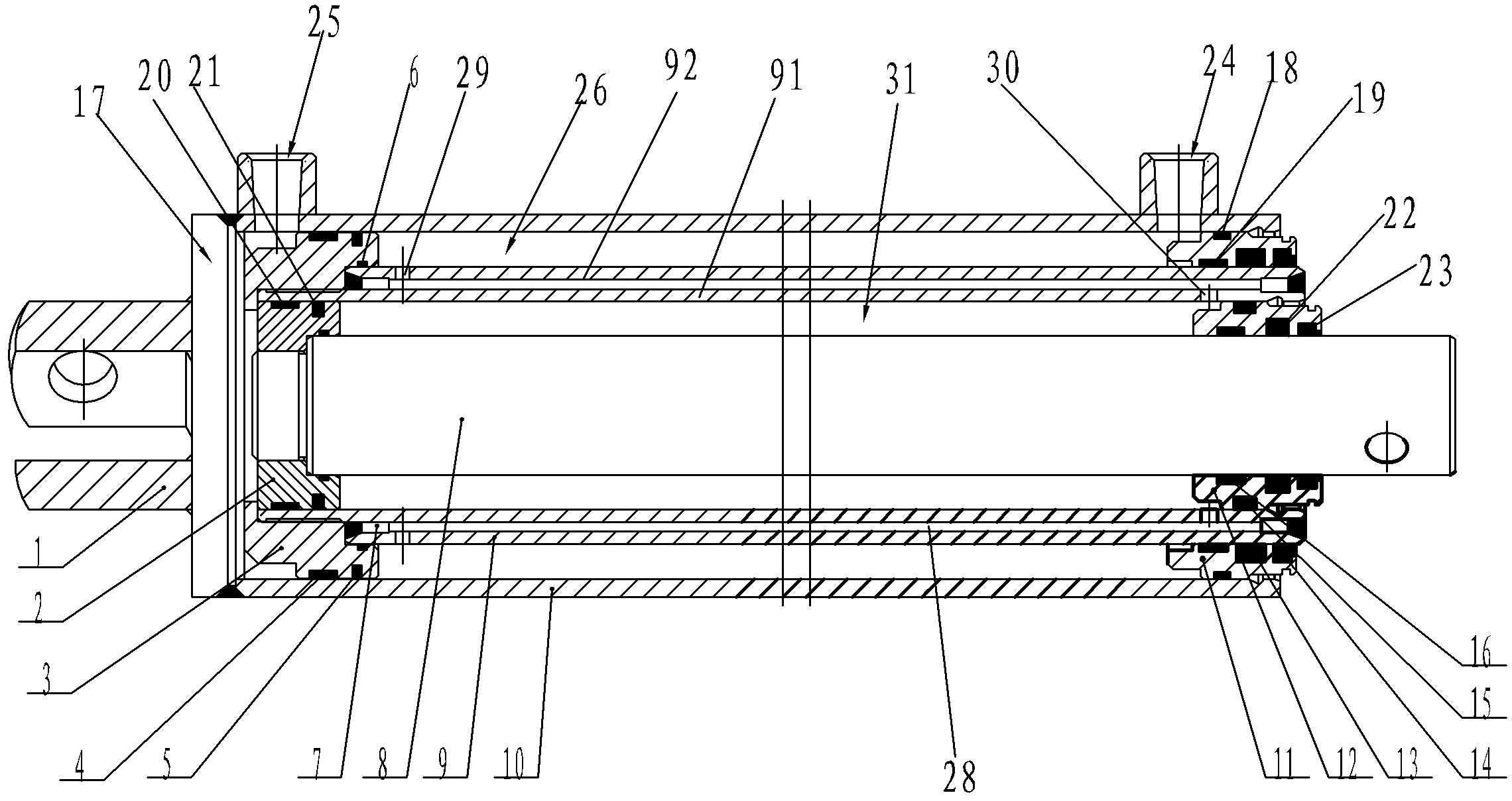

[0013] Such as figure 1 , 2 As shown, the secondary oil cylinder of the wood splitter of the present invention comprises a cylinder barrel 10, a cylinder chassis 17, a primary guide sleeve 11, a secondary guide sleeve 12, a primary piston 3, a secondary piston 2, a primary piston rod 9, a secondary Piston rod 8, the bottom end of cylinder barrel 10 is welded with cylinder chassis 17, and the bottom of cylinder chassis 17 is welded with cylinder bottom welding block 1, and first-stage piston 3 is arranged in cylinder barrel 10, and the first-stage piston 3 and cylinder barrel 10 are arranged between first-stage piston 3 and cylinder barrel 10. A support ring 4 is sealed with the first combination oil seal 5. The first-stage piston rod 9 includes an inner cylinder 91 and an outer cylinder 92. The bottom ends of the inner cylinder 91 and the outer cylinder 92 are respectively welded to the first-stage piston 3, and the first-stage piston 3 is connected to the outer cylinder. An ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com