Precise rotary table bearing with time grating detection and control

A turntable bearing and time grid technology, applied in the direction of rotating bearings, bearings, bearing components, etc., can solve the problem of not meeting the needs of high precision, and achieve the effect of simple structure, high precision measurement and control and positioning, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be described in detail with reference to the accompanying drawings.

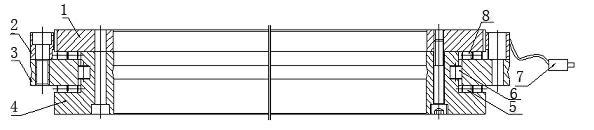

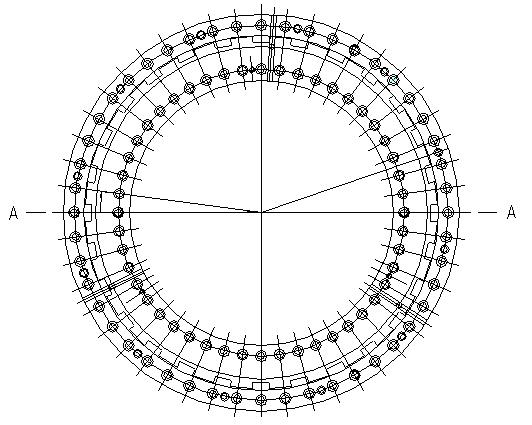

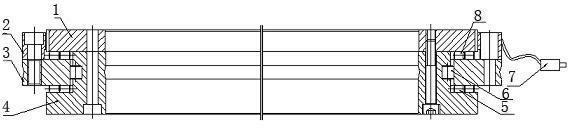

[0012] The precision turntable bearing with time grid measurement and control of this embodiment is composed of a second moving coil 1, a time grid sensor 2, a static ring 3, a first moving coil 4, a first group of cylindrical rollers 5, a second group of cylindrical rollers 6. A microprocessor 7 is formed by a third group of cylindrical rollers 8. The second moving coil 1 is installed on the end face of the first moving coil 4, and the outer circle of the second moving ring of the bearing is processed with evenly distributed teeth, and the equally divided teeth and the second moving coil are an integral structure; or on the second moving ring of the bearing The outer circle of the second moving coil is equipped with evenly distributed equally divided teeth, and the equally divided teeth are in a separate structure from the second moving coil. The equally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com