Fixing lock for ball retainer for slide rail

A cage and fixed lock technology, applied in the field of slideways and slide rails, can solve the problems of increased man-hours, complicated installation and disassembly processes, increased production costs, etc., and achieves the effects of easy manufacture, simple structure, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

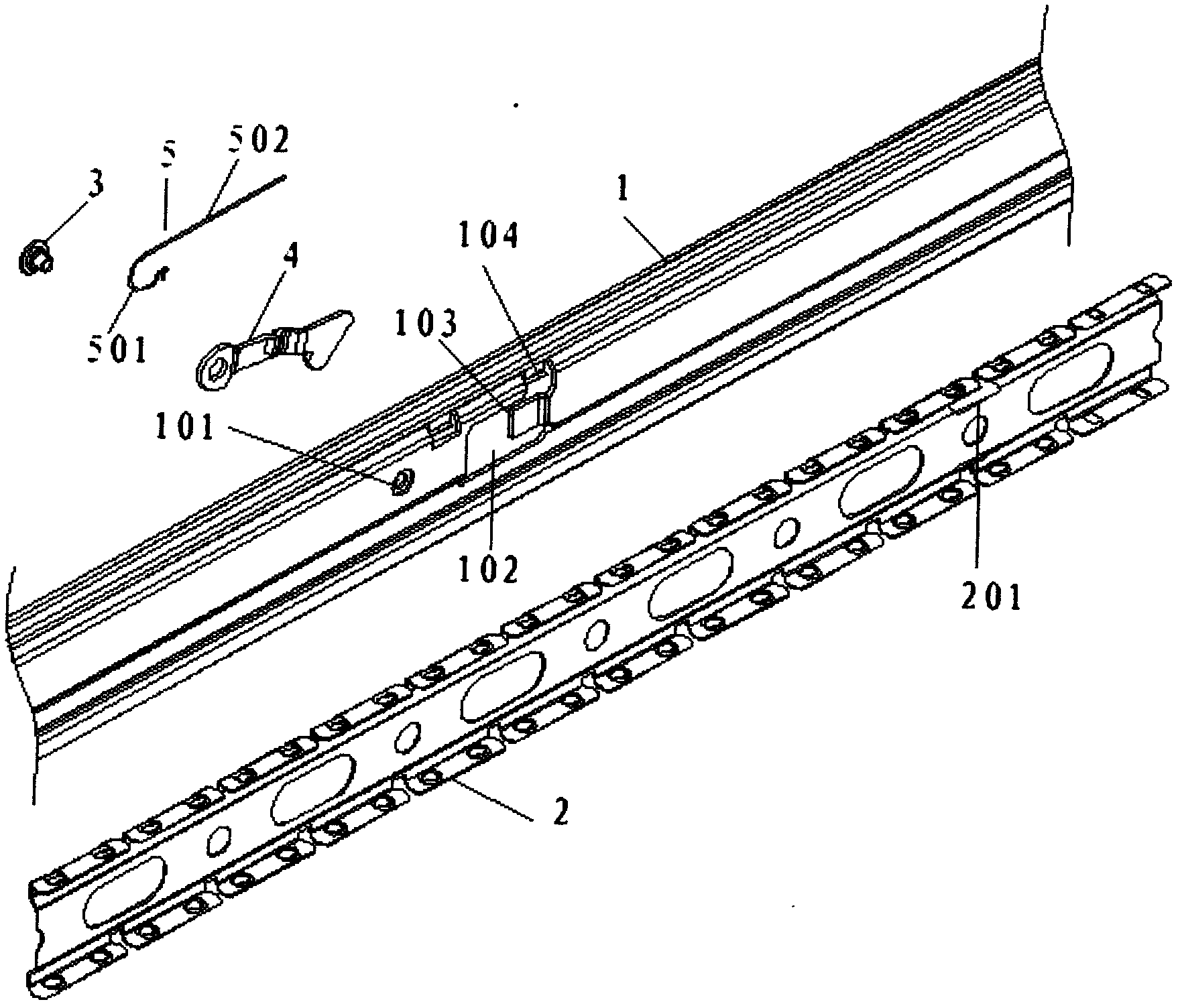

[0023] see figure 1 As shown, a ball cage fixed lock for a slide rail includes a slide rail outer frame 1 and a ball cage 2 slidably arranged in the slide rail outer frame 1 , on the slide rail outer frame 1 A fixed hole 101 and a movable cavity 102 are provided, the fixed hole 101 is located on one side of the movable cavity 102, and one end of a self-locking mechanism 4 is rotatably fixed to the outer frame 1 of the slide rail by a rivet 3 On the fixed hole 101, the other end is located in the movable cavity 102; the side of the ball cage 2 is provided with a drop groove 201, and the self-locking mechanism 4 is located at one end of the movable cavity 102. fall into the drop groove 201, thereby locking the ball cage 2 to prevent it from sliding further.

[0024] Further, one side of the movable cavity 102 is a limit stop 103 for preventing the self-locking mechanism 4 from laterally shifting, and the limit stop 103 is fixed on the outer frame 1 of the slide rail.

[0025] ...

Embodiment 2

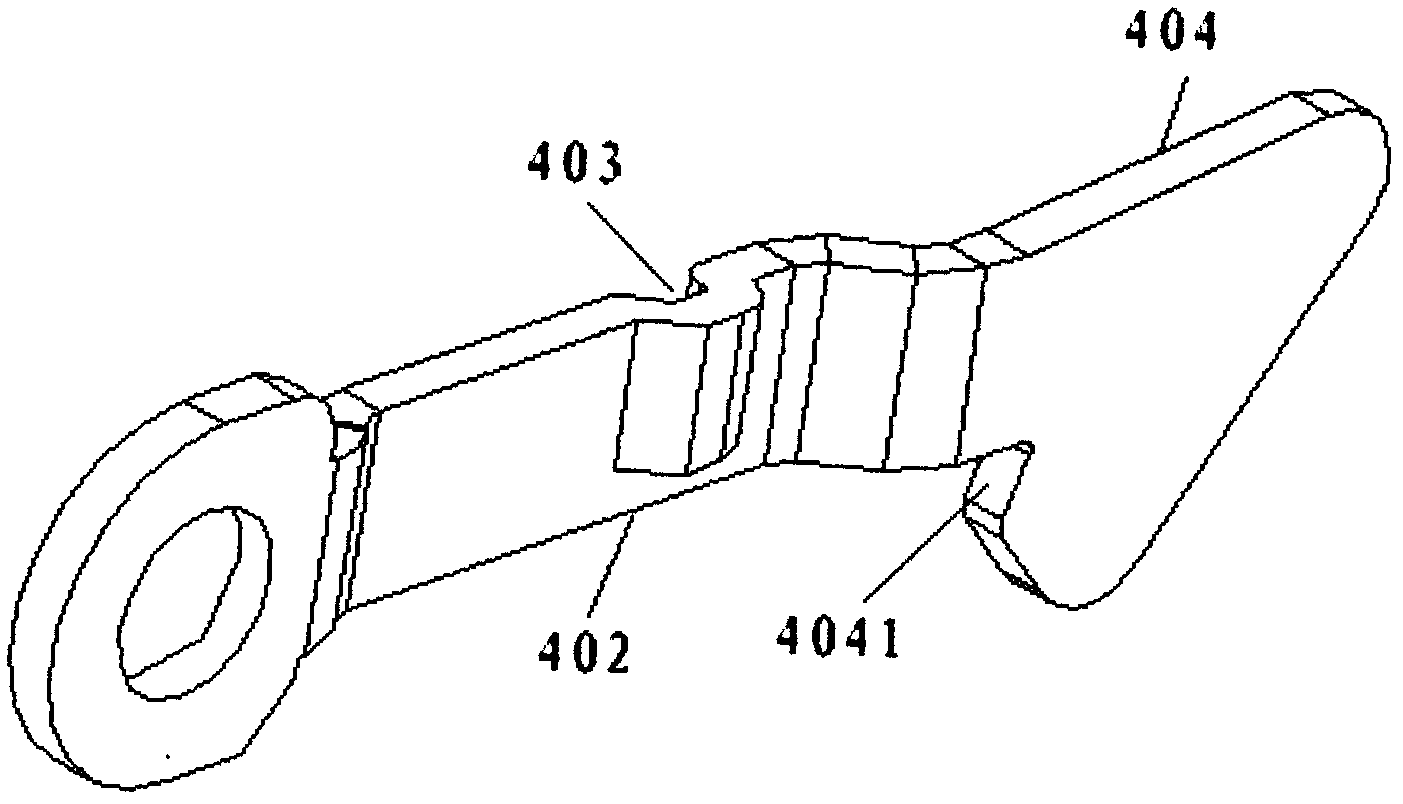

[0028] see figure 2 As shown, a ball cage fixed lock for a slide rail includes a slide rail outer frame 1 and a ball cage 2 slidably arranged in the slide rail outer frame 1 , on the slide rail outer frame 1 A fixed hole 101 and a movable cavity 102 are provided, the fixed hole 101 is located on one side of the movable cavity 102, and one end of a self-locking mechanism 4 is rotatably fixed to the outer frame 1 of the slide rail by a rivet 3 On the fixed hole 101, the other end is located in the movable cavity 102; the side of the ball cage 2 is provided with a drop groove 201, and the self-locking mechanism 4 is located at one end of the movable cavity 102. fall into the drop groove 201, thereby locking the ball cage 2 to prevent it from sliding further.

[0029] Further, one side of the movable cavity 102 is a limit stop 103 for preventing the self-locking mechanism 4 from laterally shifting, and the limit stop 103 is fixed on the outer frame 1 of the slide rail.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com