Oil burner with high-efficiency burning and low pollution emission

An oil burner, low-pollution technology, applied in the direction of burner, lighting and heating equipment, etc., can solve the problems affecting the normal use of the ignition burner, the ignition burner's own combustion loss, and the ignition air duct combustion loss, etc., to reduce carbon The effect of reducing black production, reducing emissions, and ensuring stable ignition and combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

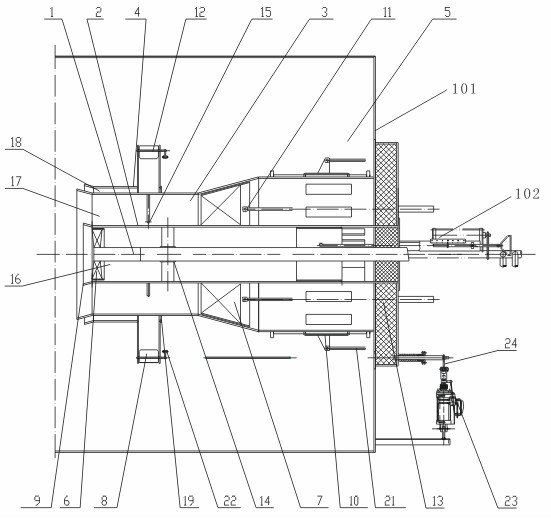

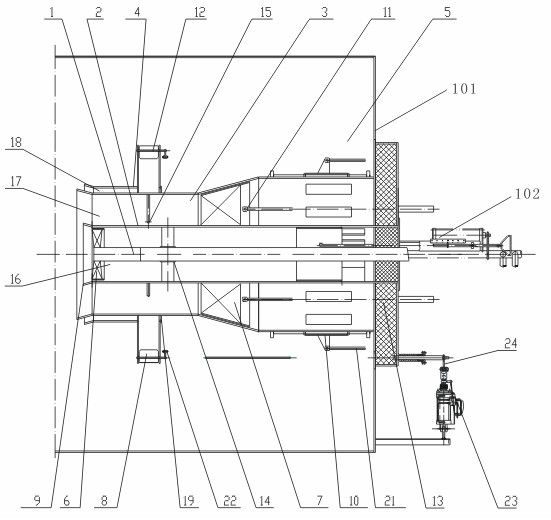

[0030] like figure 1 As shown, the high-efficiency combustion and low-pollution emission oil burner of the present invention includes an oil burner body 101, an oil burner nozzle 102 and an equal pressure air box 5. The oil burner body 101 is arranged in the equal pressure air box 5, and the equal pressure air box 5 The outside of the air box 5 is provided with a thermal insulation sealing box 13, and all the air supply for the oil burner comes from the isobaric air box 5. The oil burner body 101 includes an oil gun sleeve 1 arranged on its central axis and a primary air duct 2, a secondary air duct 3 and a classification air duct 4 which are sequentially sleeved on the periphery of the oil gun sleeve 1. The classification air duct 4. Both the secondary air duct 3 and the primary air duct 2 have the same central axis as the oil gun sleeve 1; specifically, the outer wall of the oil gun sleeve 1 is fixed with a first support frame 14, and the primary air duct 2 passes through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com