Thermostatic bath for verifying temperature sensor paired with calorimeter

A technology of temperature sensor and constant temperature bath, which is applied in the field of constant temperature bath, can solve problems such as uneven heating and uneven temperature distribution, and achieve the effects of preventing energy waste, improving measurement accuracy, and improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings. Those skilled in the art should understand that the following examples are only for the convenience of understanding and implementing the present invention, and should not limit the scope of the present invention to specific structures.

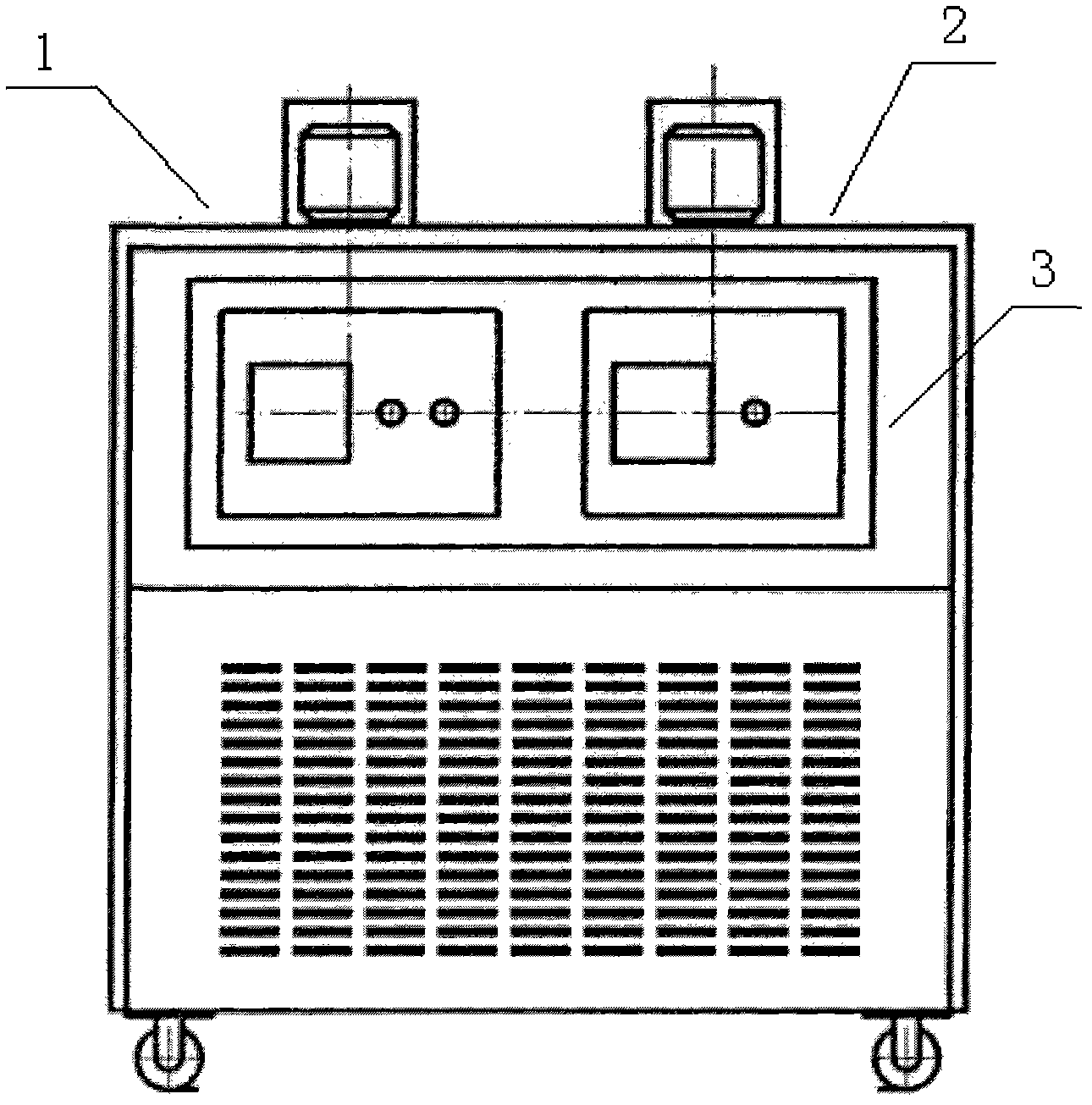

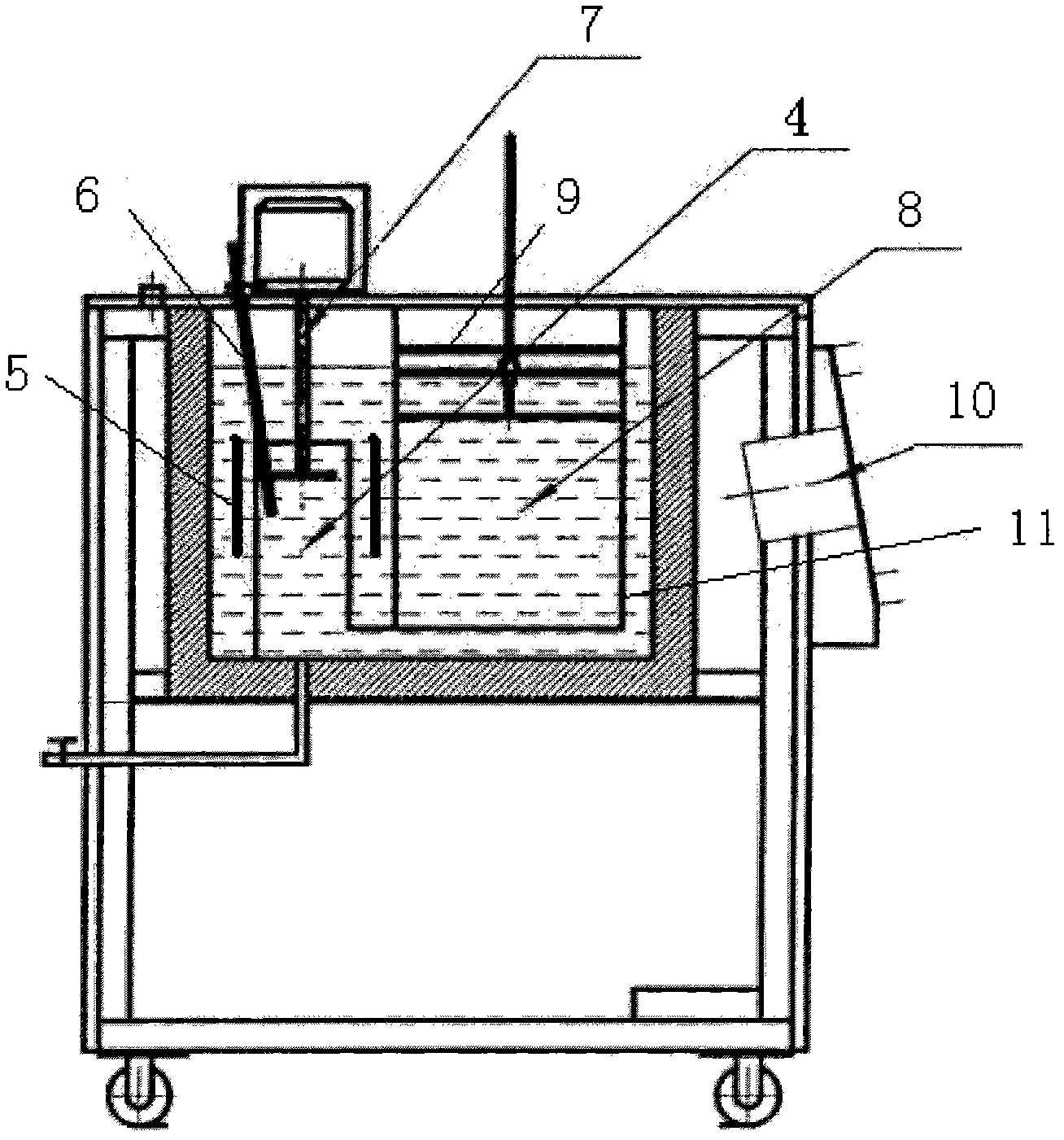

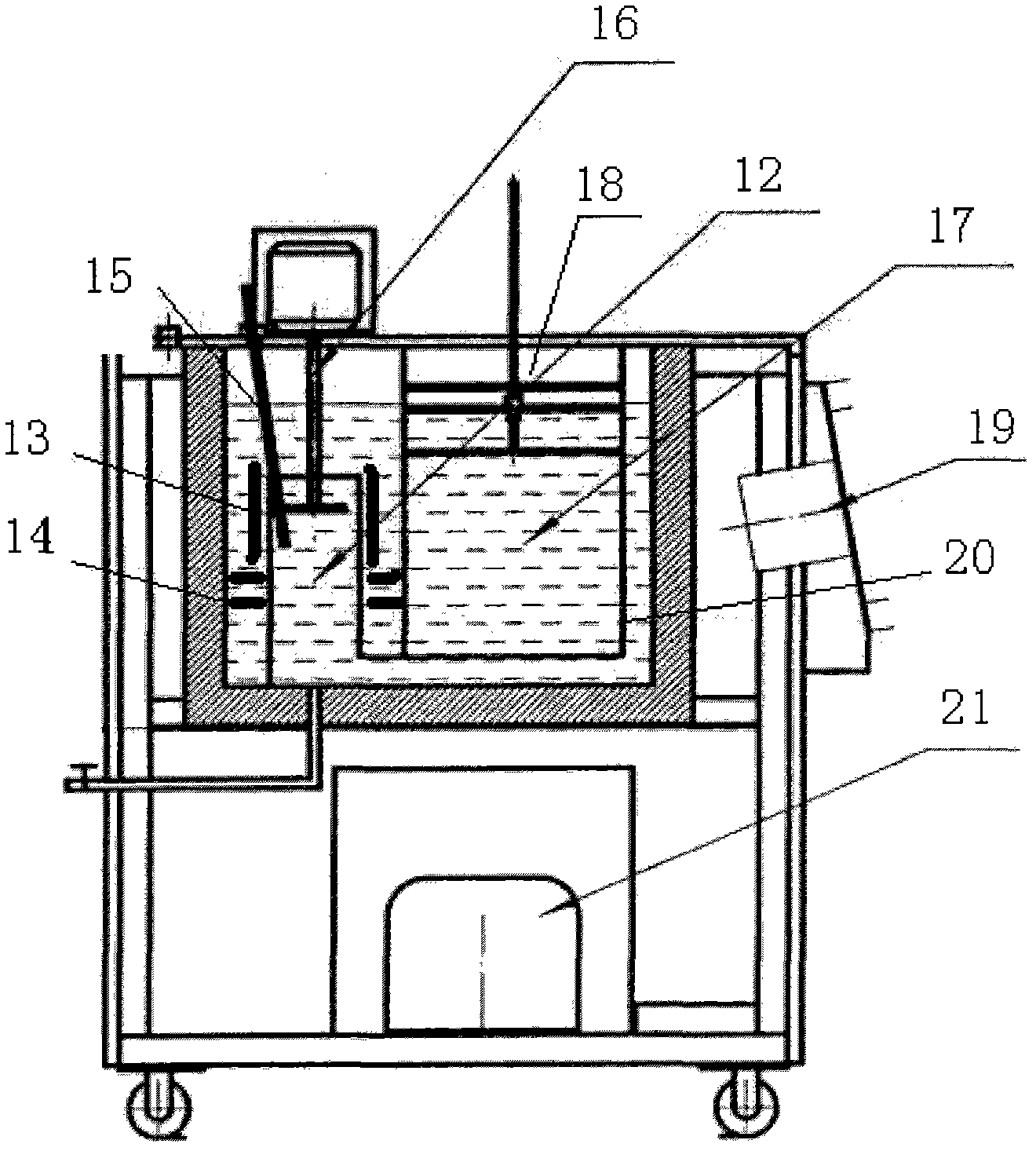

[0017] Such as figure 1 The shown temperature sensor verification constant temperature tank device includes a first tank body 1 and a second tank body 2 with different temperatures, and a control panel 3 for controlling and operating various functions of the constant temperature tank. The temperature range of the first tank 1 is: room temperature to 90°C; the temperature range of the second tank 2 is: 5°C to 90°C; the temperature of the first tank 1 and the second tank 2 can be controlled through the control panel 3, It specifically includes a large-scale temperature adjustment part and a small-scale fine-tuning part. The first tank bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com