Shearing tester

A technology of shearing test and driving machine, applied in the field of shearing instrument, which can solve the problems of deformation of shearing box and lack of shearing tester, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

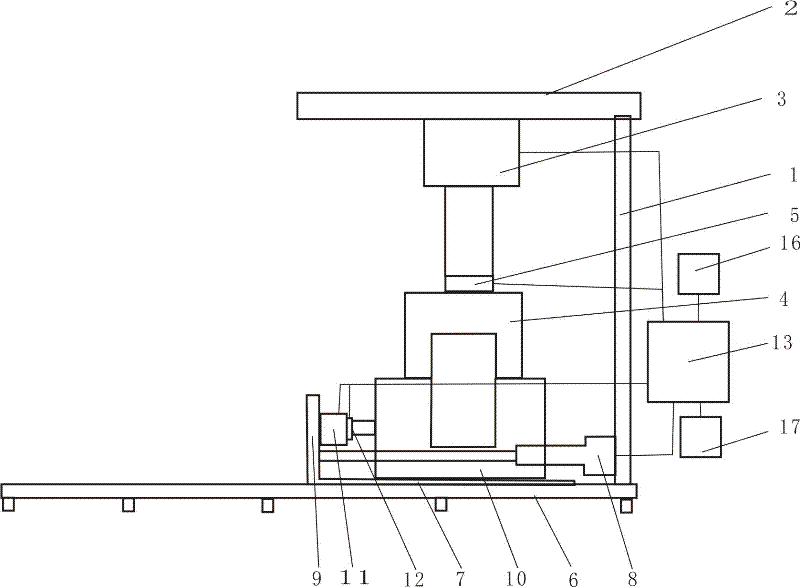

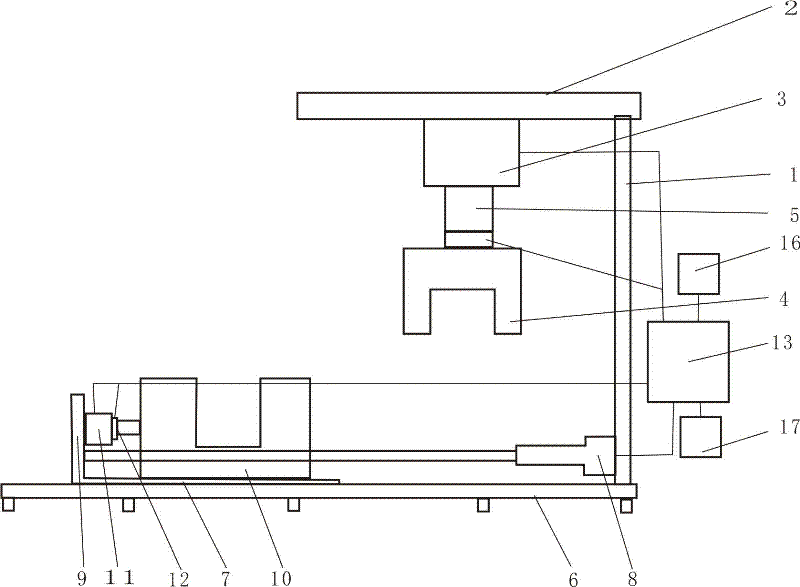

[0017] Such as figure 1 Shown, shear tester of the present invention, it comprises upper die assembly, lower die assembly and controller;

[0018] The upper mold assembly includes a bracket 1, a top block 2 fixed on the bracket, a vertical driving machine 3 is fixed below the top block 2, and the vertical driving machine 3 generally adopts an oil cylinder or an air cylinder. The lower end of machine 3 fixes upper half mold frame 4. A vertical pressure sensor 5 may be placed between the vertical driving machine 3 and the upper half frame 4 , and the vertical pressure sensor 5 is connected to a control module 13 for signals.

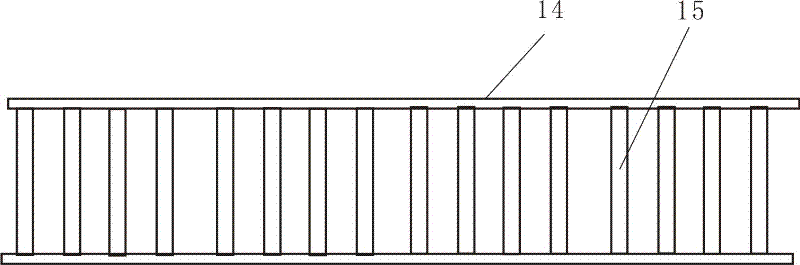

[0019] Described lower mold assembly comprises rail 6, the horizontal moving frame 7 on described rail 6, and described rail 6 comprises two parallel main rails 14, is arranged between described two parallel main rails. There are several rollers 15 (see image 3 ).

[0020] The horizontal moving frame 7 is connected with the support 1 through a horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com